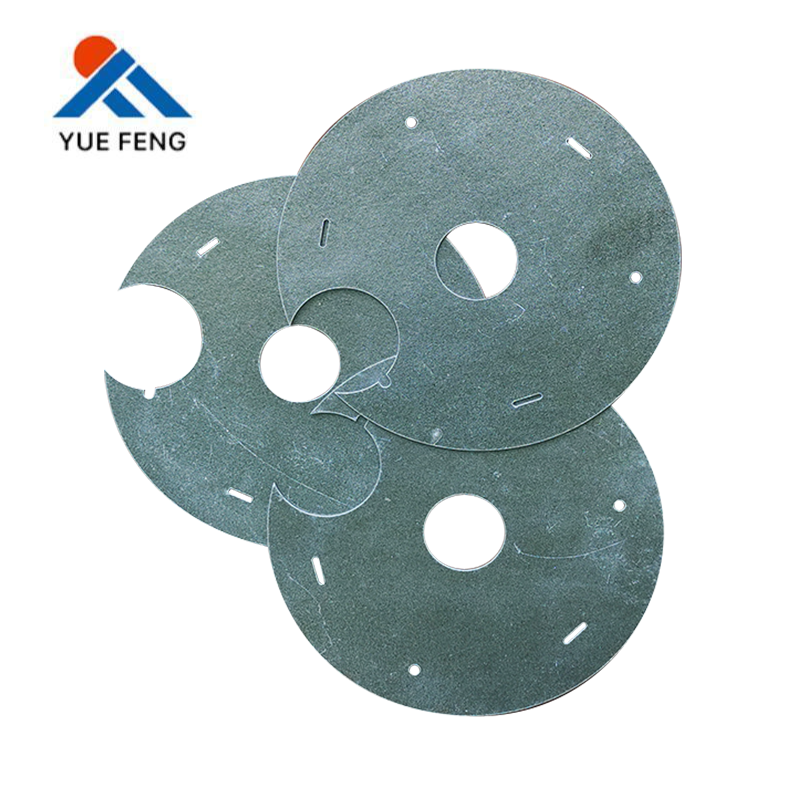

Custom Fabricated Mica Parts

Custom fabricated mica parts deliver precise solutions for complex industrial needs. Engineers value their use in specialized applications, from household appliances to automotive components. The table below highlights the market distribution:

Types and Shapes

Industrial clients request a wide range of Mica Parts, .

.

Mica tubes and sleeves provide cylindrical insulation for wires and cables.

Mica channels and troughs protect wiring in confined spaces.

Mica plates and sheets act as insulation layers or heat shields.

Complex shapes and composites meet unique industrial requirements.

Tip: Custom fabrication allows engineers to specify thickness, flexibility, and geometry, ensuring optimal performance for each application.

Key Properties

Mica Parts stand out due to their exceptional properties:

Mechanical strength and durability in harsh environments

Flexibility for intricate designs and precise tolerances

Chemical inertness, resisting corrosion and degradation

Manufacturers use several precise methods to fabricate custom mica components. Each technique offers unique advantages for different shapes, tolerances, and production volumes.

Punching: This method uses dies to cut mica sheets into specific shapes. It works well for high-volume production of washers, discs, and gaskets.

Drilling: Engineers use drilling to create holes or slots in mica plates. This process ensures accurate placement for mounting or assembly.

Milling: Milling machines remove material from mica blocks or sheets to achieve complex geometries and tight tolerances.

Die-Cutting: Die-cutting produces intricate shapes quickly and efficiently, making it ideal for thin mica sheets and high-precision parts.

Machining: Advanced CNC machining enables the creation of custom parts with detailed features and smooth finishes.

Stamping: Stamping presses form mica into desired shapes, supporting both simple and complex designs.

The choice of fabrication method directly impacts the of finished components. State-of-the-art equipment and proven processes, such as precision cutting and forming, help ensure that each part meets exact specifications. Experienced engineers optimize designs and select materials that align with mica’s unique properties, enhancing both durability and performance. Quality verification at every stage supports dimensional accuracy and long-term reliability.

Quality Control

Quality control stands at the core of every successful mica fabrication project. Manufacturers implement strict inspection protocols to detect and address defects before parts reach customers. The table below outlines :

| Defect | Description & Detection Method | Causes | Remedies & Prevention |

|---|---|---|---|

| Delamination | Surface layers peel or flake off; detected visually by surface flaking | Contamination, incompatible materials, excess release agents, moisture | Pre-dry materials, ensure clean resin, redesign mold, control release agents |

| Discoloration | Color streaks or spots visible on surface; detected visually | Residual pellets, unstable colorants, uneven mixing | Clean equipment, use stable colorants, ensure uniform mixing |

| Short Shot | Incomplete filling of mold cavities; detected by missing part sections | Blocked gates, low pressure, trapped air, cold mold, high viscosity | Redesign gates, increase pressure, raise mold temperature, improve venting |

| Burn Marks | Dark or discolored spots; detected visually and by odor | Overheated air, poor venting | Clean mold, improve venting, adjust injection speed |

| Splay | Silver or mica-like streaks on surface; visible visually | Excess moisture, overprocessing | Dry materials, optimize processing temperature and time |

| Knit Lines | Seams where flow fronts meet; visible as weak lines or seams | Mold design, flow front meeting points | Relocate gates, improve venting, allow overflow at knit lines |

| Sink Marks | Small depressions on surface, especially near ribs or bosses; visible visually | Thick projections, insufficient material injection | Redesign part thickness, add material carefully, use foaming or gas-assist molding |

| Warping | Distortion of part shape; detected visually | Non-uniform cooling, filler shape | Adjust cooling, change filler type |

| Marbling | Color inconsistency or streakiness; visible visually | Poor additive dispersion, undermixing | Increase mixing time, adjust screw speed and back pressure, reformulate colorants |

Advanced equipment, such as automated inspection systems and AI-driven quality control, further enhance precision and reduce waste. Manufacturers also use rapid prototyping to accelerate development and refine designs, ensuring high quality and reliability.

Tip: Mica’s , along with its resistance to heat, moisture, and chemicals, helps maintain the integrity of finished parts even in harsh environments.

Supplier Selection

Selecting the right supplier for custom fabricated mica parts requires careful evaluation. The following :

Manufacturer Capabilities: Choose suppliers with expertise in custom fabrication, prototyping, and assembly tailored to your requirements.

Certifications: Look for ISO 9001:2015 certification and other quality management credentials.

Compliance with Industry Standards: Ensure products meet safety and environmental standards, such as UL ratings and RoHS compliance.

Product Warranty: Review warranty policies covering defects, repairs, replacements, or refunds.

Pricing and Value: Consider overall value, including quality, experience, certifications, support, and shipping—not just cost.

: Assess the supplier’s ability to design, develop, and test custom insulation solutions.

Fabrication Technology: Confirm the use of advanced cutting and assembly technologies, such as laser and water jet cutting.

Environmental Responsibility: Evaluate the supplier’s commitment to sustainable mica sourcing and eco-friendly production.

Industry Uses

Many industries rely on for their unique properties and adaptability. The following :

| Industry | Primary Uses | Typical Volumes/Scale of Use |

|---|---|---|

| Automotive | Insulation, lightweight components, EV battery systems | Large-scale, growing with electric vehicle adoption |

| Construction | Fillers in paints, coatings, cement, and concrete | Significant, expanding with green building trends |

| Electronics | Capacitors, semiconductors, circuit insulation | Large-scale, increasing with advanced electronics |

| Cosmetics | Fillers for shimmer and texture in makeup | Notable, but smaller than industrial uses |

Aerospace, metallurgy, power generation, and appliance manufacturing also depend on mica parts for thermal and electrical insulation. Each sector demands specific properties, such as thermal stability in automotive and aerospace, or flexibility and dielectric strength in electronics.

Note: Custom fabrication allows engineers to specify thickness, shape, and performance, ensuring each part meets the exact requirements of its application.

Insulation and Heating

Mica parts play a vital role in electrical insulation and heating systems. Their make them ideal for demanding environments. Common forms include:

Mica tapes: Provide insulation in motors and transformers.

Mica gaskets and pads: Offer sealing and vibration damping in engines and high-temperature equipment.

These components prevent electrical faults, manage heat, and enhance safety. For example, , while thinner sheets in electronics protect sensitive circuits. The ability to ensures optimal performance in each application.

Custom fabricated solutions deliver .

What information should engineers provide for custom mica part orders?

Engineers should specify dimensions, material type, thickness, quantity, and application details. Clear drawings or CAD files help ensure accurate fabrication.

How does Yuefeng Mica ensure quality in custom parts?

Yuefeng Mica uses advanced inspection systems, strict process controls, and certified materials. Their team verifies each part meets customer specifications before shipment.

Can custom mica parts withstand extreme temperatures?

Yes, custom mica parts maintain structural integrity at temperatures up to 1600°C.

They resist thermal shock and provide