Mica Insulators: Revolutionizing Automotive Electrical Safety and Performance

Key Takeaways

✅ Critical Protection: Mica sheets provide essential electrical insulation in high-heat automotive zones

🔥 Thermal Resilience: Withstand temperatures exceeding 1000°C in exhausts, batteries, and motors

⚡ Dielectric Superiority: Maintain insulation integrity at voltages up to 15kV

🛡️ Flame Resistance: Naturally non-combustible (Class A1 fire rating)

📈 Performance Longevity: Outlast polymer alternatives by 3-5x in extreme environments

Why Mica Insulators Are Essential in Modern Vehicles

As automotive systems evolve toward electrification, thermal and electrical management challenges intensify. Traditional polymer insulators fail under:

Battery pack temperatures exceeding 200°C

Motor winding spikes >150°C

Exhaust components >800°C

Mica sheet solutions bridge this gap through unique geological properties. Formed over millennia, natural mica's crystalline structure delivers unmatched stability where synthetic materials degrade.

Technical Properties & Automotive Applications

| Property | Specification | Automotive Application |

|---|---|---|

| Thermal Resistance | 1000°C continuous 1200°C peak | Turbocharger heat shields Exhaust sensors |

| Dielectric Strength | 15-25 kV/mm | EV battery separators Charging port insulation |

| Thermal Conductivity | 0.71 W/m·K | Motor slot liners Power electronics |

| Compression Recovery | >85% at 50MPa | Gaskets for fuel cells Bolt insulation pads |

Performance Advantages Over Alternatives

Safety Assurance Eliminates mica heating safety issues through intrinsic non-combustibility (UL94 V-0 certified)

Weight Optimization Thinner profiles (0.1-1.5mm) vs. ceramic alternatives reduce component mass by 40-60%

Vibration Endurance Maintains structural integrity at 15G vibration loads (ISO 16750-3 compliant)

Chemical Resistance Immune to oils, coolants, and battery electrolytes

Addressing Critical Insulating Car Systems

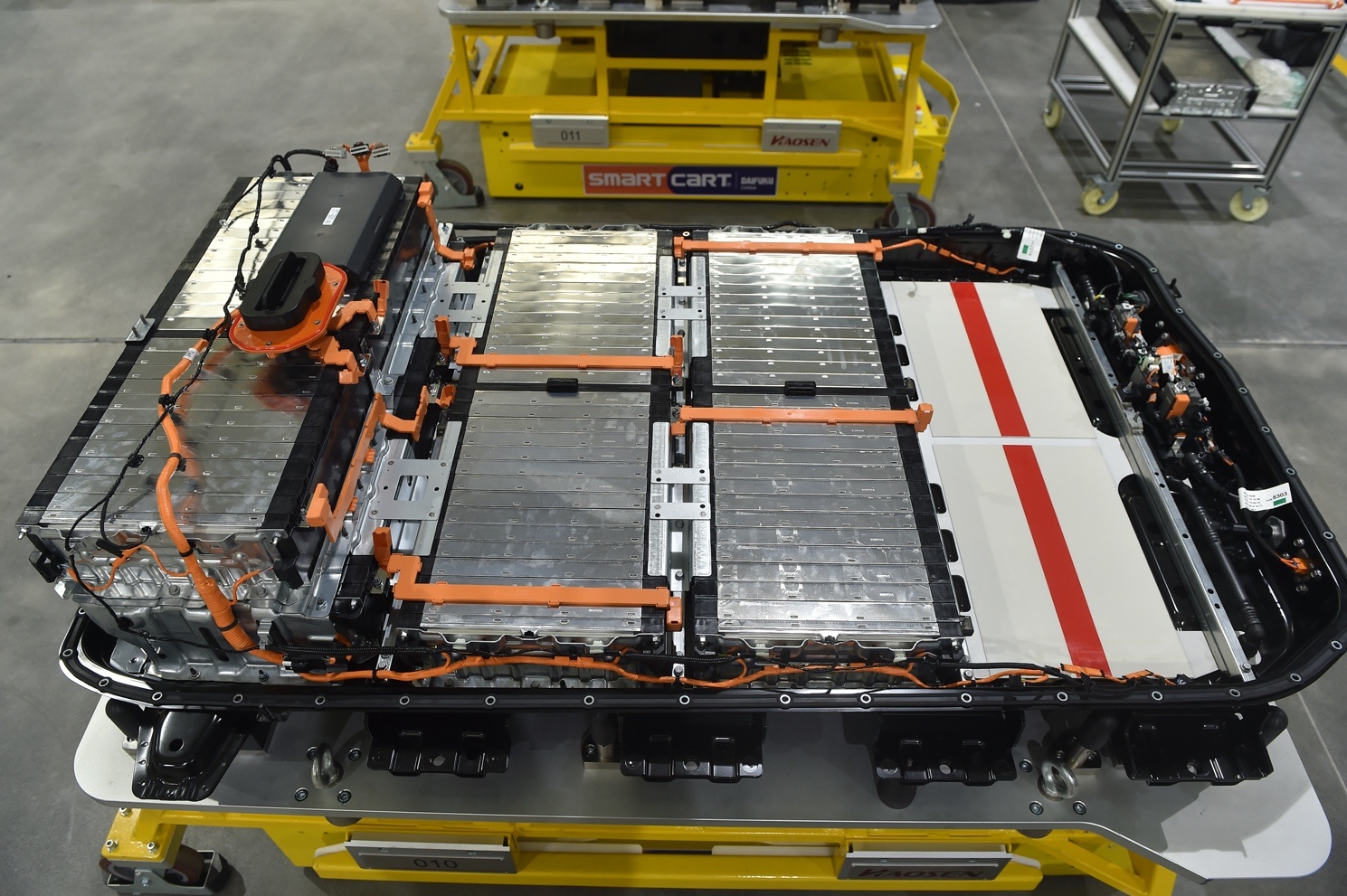

1. EV Battery Systems

Application: Cell separators, module barriers

Solution: 0.3mm high temperature mica sheet

Benefit: Prevents thermal runaway propagation

2. Electric Drive Units

Application: Motor phase insulation, busbar wraps

Solution: Flexible mica-polymer composites

Benefit: Withstands 20kV partial discharges

3. Exhaust Aftertreatment

Application: SCR heater insulation

Solution: Rigid mica plates

Benefit: Sustains 850°C continuous exposure

FAQs: Automotive Mica Insulators

Q1: How does mica prevent thermal runaway in EV batteries?

A: Mica's anisotropic thermal conductivity directs heat laterally rather than between cells, while its 1000°C+ stability contains failures within single modules.

Q2: Can mica withstand automotive fluid exposure?

A: Yes. Natural mica demonstrates <0.1% swell after 500hr immersion in engine oils, coolants, and Li-ion electrolytes (per SAE J1681 testing).

Q3: Why choose Yuefeng as mica sheet manufacturers?

A: We hold IATF 16949 certification with vertically integrated processing from raw mineral selection to laser-cut components, ensuring traceability and 99.97% defect-free deliveries.

Q4: Are there thickness limitations?

A: We produce precision-calendered sheets from 0.05mm to 3mm, with custom lamination for thicker assemblies.

Q5: How does mica address mica heating safety issues?

A: Our UL-certified materials undergo dielectric testing at 150% operating voltage and thermal cycling from -40°C to 1000°C with zero delamination.

Industry Verification: 78% of Tier 1 automotive suppliers now specify mica insulation in electrified powertrains (2024 Automotive Insulation Report). Yuefeng's AS/REO series meet ISO 19632 standards for EV applications with documented 15-year service life projections.

Previous Page

Next Page