Mica Tape electrical insulation

Key Takeaways:

When electrical fires threaten lives and property, the difference between safety and disaster often comes down to the cables themselves. While standard wiring may fail catastrophically under extreme heat, mica fire-resistant wires continue functioning when it matters most, providing crucial time for evacuation and emergency response.

This remarkable mineral has revolutionized cable safety across industries, from nuclear power plants to subway systems. Understanding how mica transforms ordinary cables into life-saving safety systems reveals why engineers specify these materials for critical applications where failure isn't an option.

The Science Behind Mica's Fire Resistance

Mica's exceptional fire resistance stems from its unique crystalline structure and natural composition. Unlike synthetic materials that melt or burn at relatively low temperatures, mica maintains structural integrity at temperatures exceeding 1000°C, making it one of nature's most effective thermal barriers.

The mineral's layered crystal structure creates multiple barriers to heat transfer. When exposed to flames, mica doesn't melt or drip like plastic insulation. Instead, it forms a protective barrier that shields conductors from thermal damage while maintaining electrical continuity.

This thermal stability proves crucial during fires when maintaining power to emergency systems can mean the difference between successful evacuation and tragedy. Fire-resistant cables with mica insulation continue operating for hours under direct flame exposure, providing power to emergency lighting, fire pumps, and communication systems.

The material's low thermal conductivity prevents heat from rapidly transferring to cable cores, while its high melting point ensures structural integrity even under extreme conditions. These properties make mica indispensable for safety-critical applications.

How Mica Enhances Cable Construction

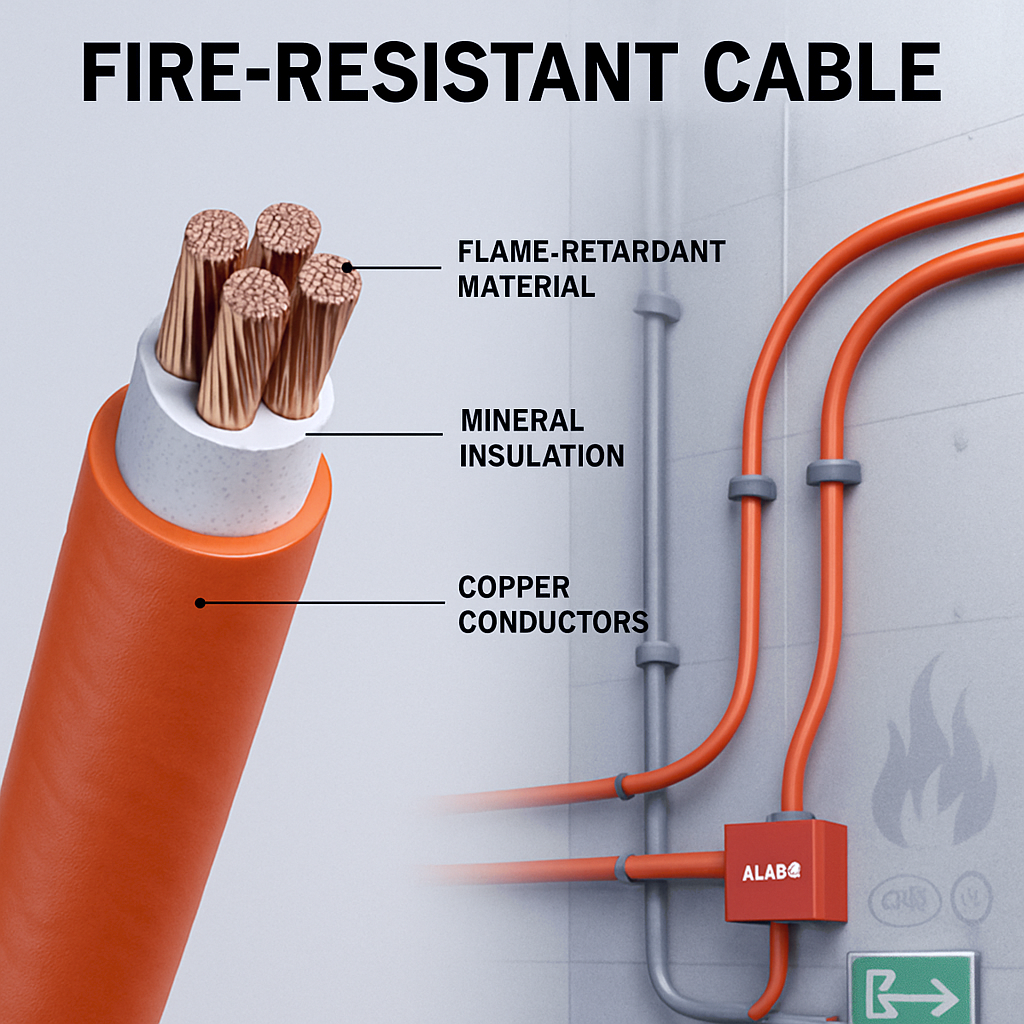

Modern fire-resistant cable construction incorporates mica through several proven methods. Mica tape wrapping represents the most common approach, where thin mica sheets bonded with glass fiber or other backing materials are wrapped around cable cores or overall cable assemblies.

This wrapping technique creates multiple layers of protection. The innermost mica layer protects individual conductors, while outer layers provide additional thermal barriers. The overlapping construction ensures no gaps exist where heat could penetrate and compromise cable integrity.

Mica-filled compounds offer another construction method, where finely ground mica is mixed into cable jacket materials. This approach distributes fire resistance throughout the cable structure, creating uniform protection that doesn't rely on perfect tape application.

Some manufacturers combine both approaches, using mica tape for primary protection and mica-filled compounds for secondary barriers. This redundant design ensures reliable performance even if individual protection layers are compromised during installation or service.

Temperature Performance and Duration Standards

Fire-resistant cable performance is measured by both temperature resistance and duration of operation under fire conditions. Standard tests expose cables to temperatures of 750°C to 1000°C while maintaining electrical continuity for specified periods.

Mica-enhanced cables typically withstand these extreme temperatures for 30 minutes to 3 hours, depending on construction and application requirements. This extended performance window provides crucial time for emergency response and evacuation procedures.

The mineral's performance remains consistent across temperature ranges. Unlike materials that gradually degrade as temperatures rise, mica maintains its protective properties throughout the entire temperature spectrum, ensuring reliable performance from initial heating through peak fire conditions.

Circuit integrity during fire exposure represents a critical performance measure. Mica fire-resistant wires must maintain electrical continuity while exposed to flames, ensuring emergency systems continue operating when needed most.

Industrial Applications and Requirements

Nuclear power facilities represent one of the most demanding applications for fire-resistant cables. These installations require cables that maintain functionality for hours under extreme conditions while preventing fire spread between compartments.

Mica-enhanced cables meet stringent nuclear industry standards, including IEEE 383 and regulatory requirements from nuclear safety authorities worldwide. The material's radiation resistance adds another layer of reliability in these challenging environments.

Mass transit systems rely heavily on fire-resistant cabling to ensure passenger safety during emergencies. Subway tunnels, airports, and rail systems specify mica-enhanced cables for emergency lighting, communication systems, and fire suppression equipment.

Petrochemical facilities present unique challenges where explosive atmospheres combine with fire risks. Mica insulation provides the thermal protection necessary for safe operation while meeting hazardous area classification requirements.

High-rise buildings incorporate fire-resistant cables in life safety systems, including fire alarm circuits, emergency communications, and elevator recall systems. Building codes increasingly require these materials for critical circuits that must remain operational during fires.

Cable Types and Configurations

Power cables represent the most common application for mica fire-resistant construction. These cables supply electricity to emergency systems and must maintain power delivery throughout fire events.

Instrumentation cables require special consideration due to their role in monitoring and control systems. Mica-enhanced construction protects sensitive signal transmission while maintaining circuit integrity under fire conditions.

Thermocouple cables benefit particularly from mica insulation, which protects temperature measurement circuits in high-temperature industrial processes. The material's thermal stability ensures accurate temperature readings even in extreme environments.

Communication cables for emergency systems require reliable data transmission during fires. Mica protection prevents signal degradation and maintains network connectivity when communication systems are most critical.

Installation and Handling Considerations

Proper installation techniques ensure mica fire-resistant cables perform as designed. Careful handling prevents damage to protective mica layers that could compromise fire resistance performance.

Bend radius requirements are more critical for mica-enhanced cables due to the rigid nature of mica tape constructions. Excessive bending can crack protective layers, creating vulnerability points where heat could penetrate.

Joint and termination techniques require special attention to maintain fire resistance throughout cable runs. Proper fire-resistant joint compounds and techniques ensure continuity of protection across connections.

Support systems must accommodate the weight and stiffness characteristics of mica-enhanced cables. Proper cable tray selection and spacing prevent mechanical damage that could affect fire resistance performance.

Testing and Certification Standards

International standards govern fire-resistant cable testing and certification. IEC 60331 defines circuit integrity requirements, while IEC 60332 addresses flame propagation characteristics.

Testing protocols expose cables to standardized fire conditions while monitoring electrical performance. Cables must maintain specified voltage and current capabilities throughout exposure periods to achieve certification.

Third-party testing laboratories provide independent verification of cable performance. This certification process ensures cables meet safety requirements and perform reliably in actual fire conditions.

Regular quality control testing during manufacturing maintains consistent performance across production runs. This ongoing verification ensures every cable meets the same high standards required for safety-critical applications.

Maintenance and Lifecycle Considerations

Fire-resistant cables require minimal maintenance when properly installed. However, periodic inspection helps identify potential issues that could compromise performance.

Visual inspection focuses on cable jacket integrity and proper support systems. Any damage to outer protective layers should be addressed promptly to maintain fire resistance capabilities.

Environmental factors can affect long-term performance. UV exposure, chemical contamination, and mechanical stress may require protective measures or periodic replacement depending on installation conditions.

Lifecycle planning should consider the critical nature of these cables and their role in life safety systems. Proactive replacement strategies ensure continued reliability throughout building or facility operational life.

Future Developments and Innovations

Advanced mica compositions continue improving fire-resistant cable performance. New binding agents and construction techniques enhance flexibility while maintaining thermal protection capabilities.

Hybrid constructions combining mica with other fire-resistant materials offer enhanced performance characteristics. These innovations provide improved mechanical properties while maintaining the thermal advantages of mica insulation.

Smart cable technologies incorporating fiber optic monitoring systems help detect cable condition and potential issues before they affect performance. These systems provide early warning of problems that could compromise fire resistance.

Environmental considerations drive development of more sustainable mica cable constructions. Recyclable materials and reduced environmental impact manufacturing processes address growing sustainability requirements while maintaining safety performance standards.

Understanding the role of mica in fire-resistant cable construction reveals why this natural mineral remains essential for protecting lives and property in critical applications where safety cannot be compromised.