Mica Insulators for Automotive - Electric Vehicle

The electric vehicle revolution demands advanced materials that can handle extreme operating conditions while ensuring passenger safety. As automotive manufacturers push the boundaries of performance with higher voltages, increased charging speeds, and more compact battery designs, traditional insulation materials often fall short. This is where mica insulation emerges as the superior choice for electric vehicle applications.

Mica, a naturally occurring mineral with exceptional properties, has become indispensable in modern EV manufacturing. From battery thermal management to motor winding protection, this versatile insulation material provides the reliability and performance that electric vehicles require. Understanding how mica enhances EV safety and efficiency reveals why leading manufacturers consistently choose these advanced materials over conventional alternatives.

Why Electric Vehicles Need Advanced Insulation Materials

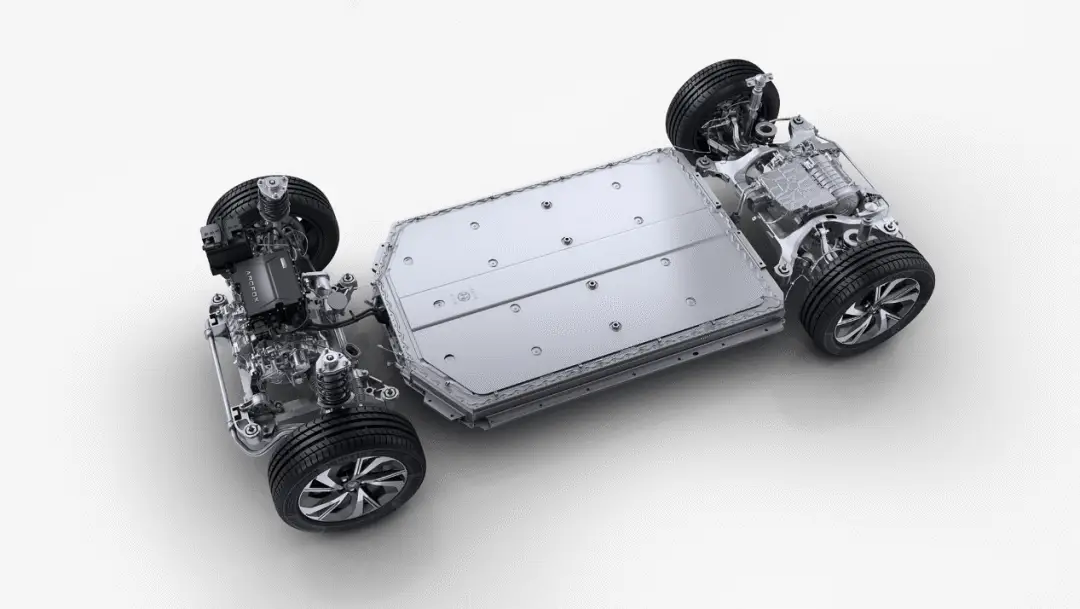

Electric vehicles operate under significantly more demanding conditions than traditional combustion engines. The shift to high voltage systems, often exceeding 800 volts in modern EVs, creates intense electrical stress that requires superior insulation protection. Additionally, rapid charging technologies generate substantial heat that must be managed effectively to prevent thermal runaway and ensure battery longevity.

The compact nature of EV designs compounds these challenges. Battery packs, electric motors, and power electronics must fit into limited spaces while maintaining safe operating temperatures. Traditional insulation materials like plastics and rubber often degrade under these extreme conditions, potentially compromising vehicle safety and performance.

addresses these challenges through its unique combination of electrical insulation and thermal stability. Unlike synthetic materials that can fail catastrophically when exposed to high temperatures, mica maintains its protective properties even under the most demanding EV operating conditions.

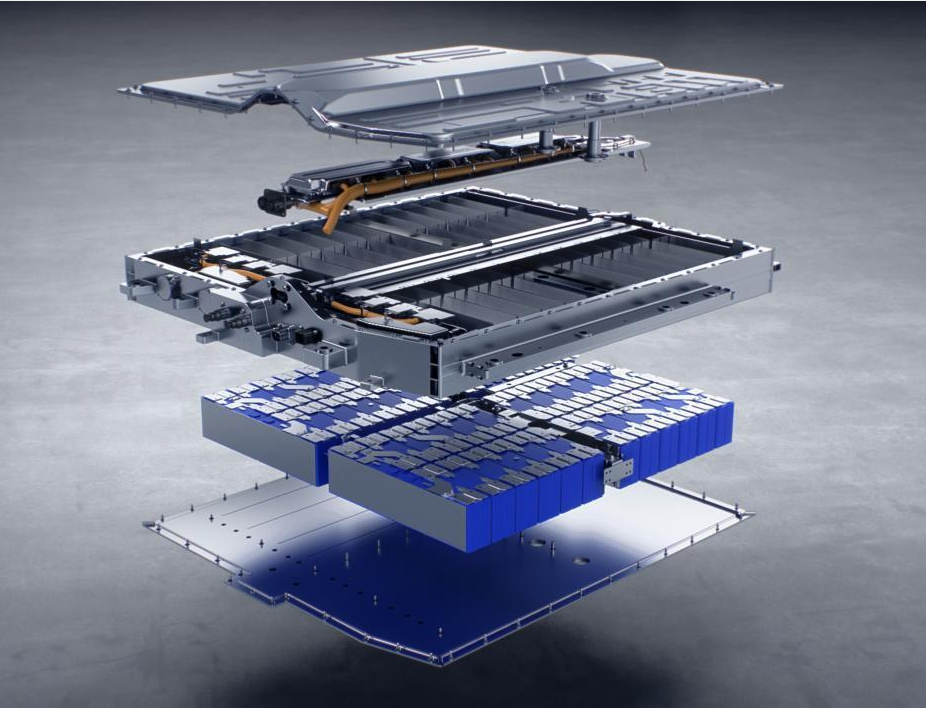

Battery Pack Thermal Management: The Critical Safety Component

Battery thermal management represents one of the most critical safety challenges in electric vehicle design. Lithium-ion batteries generate significant heat during charging and discharging cycles, and uncontrolled temperature increases can lead to thermal runaway - a dangerous condition that can result in fire or explosion.

Mica insulation provides essential high-temperature protection by creating thermal barriers between individual battery cells. When one cell begins to overheat, mica barriers prevent heat transfer to adjacent cells, effectively containing thermal propagation and maintaining overall pack safety. This protective function becomes especially important during high frequency charging cycles where rapid energy transfer generates intense heat.

The water resistant properties of mica also prove valuable in battery applications. Unlike traditional insulation materials that can absorb moisture and lose their protective properties, mica maintains consistent performance even when exposed to humidity or condensation. This reliability ensures long-term protection throughout the vehicle's operational life.

conform to complex battery pack geometries while maintaining their insulation layer integrity. This flexibility allows manufacturers to optimize pack designs for maximum energy density while ensuring comprehensive thermal protection.

Electric Motor Insulation: Performance Under Extreme Conditions

Electric vehicle motors operate under conditions that would destroy conventional insulation systems within months. These motors must handle high voltage electrical stress while generating tremendous mechanical forces and heat during operation. The combination of electrical, thermal, and mechanical stress requires insulation materials with exceptional durability.

Motor windings wrapped with mica insulation maintain their protective properties even when subjected to extreme highs of temperature and voltage. The material's natural corrosion resistance prevents degradation from exposure to moisture, oils, and other automotive fluids that could compromise insulation integrity.

High performance electric motors in premium EVs often operate at higher speeds than traditional automotive applications. The mechanical stress generated by high-speed rotation, combined with the thermal cycling from acceleration and regenerative braking, creates demanding conditions that only advanced materials like mica can withstand reliably.

The heat resistant characteristics of mica become particularly important during sustained high-power operation. While synthetic insulation materials may soften or degrade when exposed to continuous high temperatures, mica maintains its structural integrity and electrical properties, ensuring consistent motor performance throughout the vehicle's lifespan.

Power Electronics and Control Systems Protection

Modern electric vehicles incorporate sophisticated power electronics that manage energy flow between the battery, motor, and charging systems. These components operate with power cables carrying hundreds of volts and significant current loads, requiring robust insulation to prevent electrical faults and ensure system reliability.

Control cables throughout the vehicle carry critical signals that coordinate various EV systems, from battery management to motor control. These low-voltage circuits require protection from electromagnetic interference while maintaining signal integrity over a wide range of operating temperatures.

provide essential insulation for high-voltage connections in power electronics modules. These components must maintain their sealing and insulation properties despite exposure to thermal cycling, vibration, and potential fluid contamination.

The radio frequency interference generated by modern power electronics can disrupt sensitive control systems. Mica's natural electromagnetic shielding properties help protect control circuits while maintaining primary insulation functions, supporting the complex electronic integration required in advanced EVs.

Charging Infrastructure and Power Management

The transition to rapid charging technologies creates new challenges for insulation materials. DC fast charging systems can deliver power levels exceeding 350 kilowatts, generating substantial heat and electrical stress in charging cables and vehicle-side connections.

Power cords used in charging applications must maintain their insulation properties despite repeated flexing, exposure to weather conditions, and thermal cycling from ambient to elevated temperatures. Traditional insulation materials often crack or degrade under these demanding conditions, potentially creating safety hazards.

Mica-based insulation in charging infrastructure provides the thermal stability and electrical reliability required for safe rapid charging. The material's ability to withstand extreme temperatures ensures consistent protection even during extended high-power charging sessions.

Vehicle-side charging ports benefit from mica's flame-retardant properties, which provide additional safety margins in the event of electrical faults. This natural fire resistance, combined with excellent electrical insulation, makes mica an ideal choice for critical charging system components.

Industrial Applications and Manufacturing Advantages

The automotive industry's adoption of mica insulation reflects broader industrial applications where high temperature resistance and electrical reliability are essential. From rail transit systems to aerospace applications, mica has proven its value in demanding environments similar to those found in electric vehicles.

Manufacturing processes for mica-based insulation materials have evolved to meet automotive quality standards while maintaining cost-effectiveness. offers consistent properties and precision thickness control that supports automated manufacturing processes.

Quality control systems ensure that mica insulation materials meet stringent automotive standards for electrical power applications. Testing protocols verify performance under conditions that simulate years of vehicle operation, providing confidence in long-term reliability.

The scalability of mica production supports the growing electric vehicle market without compromising material quality. As EV production volumes increase, mica suppliers have demonstrated the ability to meet demand while maintaining the high standards required for automotive applications.

Environmental Benefits and Sustainability

Sustainability considerations increasingly influence automotive material selection, and mica offers several environmental advantages over synthetic alternatives. As a naturally occurring mineral, mica requires less energy-intensive processing compared to petroleum-based insulation materials.

The durability of mica insulation supports vehicle longevity by reducing component failures and maintenance requirements. This extended service life contributes to overall vehicle sustainability by minimizing replacement parts and reducing waste throughout the vehicle's lifecycle.

End-of-life recyclability becomes increasingly important as electric vehicle production scales. Mica components can be recovered and reprocessed more easily than complex synthetic materials, supporting circular economy principles in automotive manufacturing.

The heat resistance and chemical stability of mica eliminate the need for additional protective coatings or treatments that might introduce environmental concerns. This inherent stability simplifies material sourcing and processing while maintaining performance standards.

Future Developments in EV Insulation Technology

The electric vehicle industry continues evolving toward higher performance and greater efficiency, creating new opportunities for advanced mica applications. Solid-state battery technologies present unique insulation challenges that mica's properties may help address.

Wireless charging systems generate electromagnetic fields that require specialized insulation materials capable of handling both thermal and RF energy. Mica's natural properties position it well for these emerging applications.

Integration with smart sensors and monitoring systems may enable predictive maintenance of insulation components. capabilities continue advancing to support these intelligent material applications.

The development of autonomous vehicles creates additional reliability requirements for all vehicle systems, including insulation materials. Mica's proven track record in demanding applications provides confidence for autonomous vehicle designers.

Conclusion: Enabling the Electric Future

Mica insulation materials provide the foundation for safe, reliable electric vehicle operation across a wide range of applications. From battery thermal management to motor protection, these versatile materials deliver the performance characteristics that enable modern EV technology.

As the automotive industry continues its transition to electrification, the demand for high-performance insulation materials will only increase. Mica's unique combination of thermal stability, electrical reliability, and environmental compatibility positions it as an essential component in the electric vehicle revolution.