5 Key Industrial Applications of Mica You Should Know

Mica stands out in industry for its unique combination of dielectric strength, heat resistance, and chemical stability. Companies rely on mica in many sectors because it , keeping its structure and function over time. The most common applications of mica include , where it improves durability, insulation, and performance.

Key Takeaways

Mica is a powerful natural insulator that protects electrical equipment from heat and electrical damage, making devices safer and more reliable.

Its excellent heat resistance helps industries save energy and stay safe by preventing damage in high-temperature environments like furnaces and engines.

In construction, mica improves material strength and durability, creating smoother surfaces and fire-resistant buildings that last longer.

Mica adds shine and protection to paints and coatings, keeping surfaces bright and resistant to weather, wear, and fading.

Automotive and aerospace industries rely on mica for insulation and safety, helping vehicles and aircraft perform better under tough conditions.

1. Electrical Insulation

Dielectric Properties

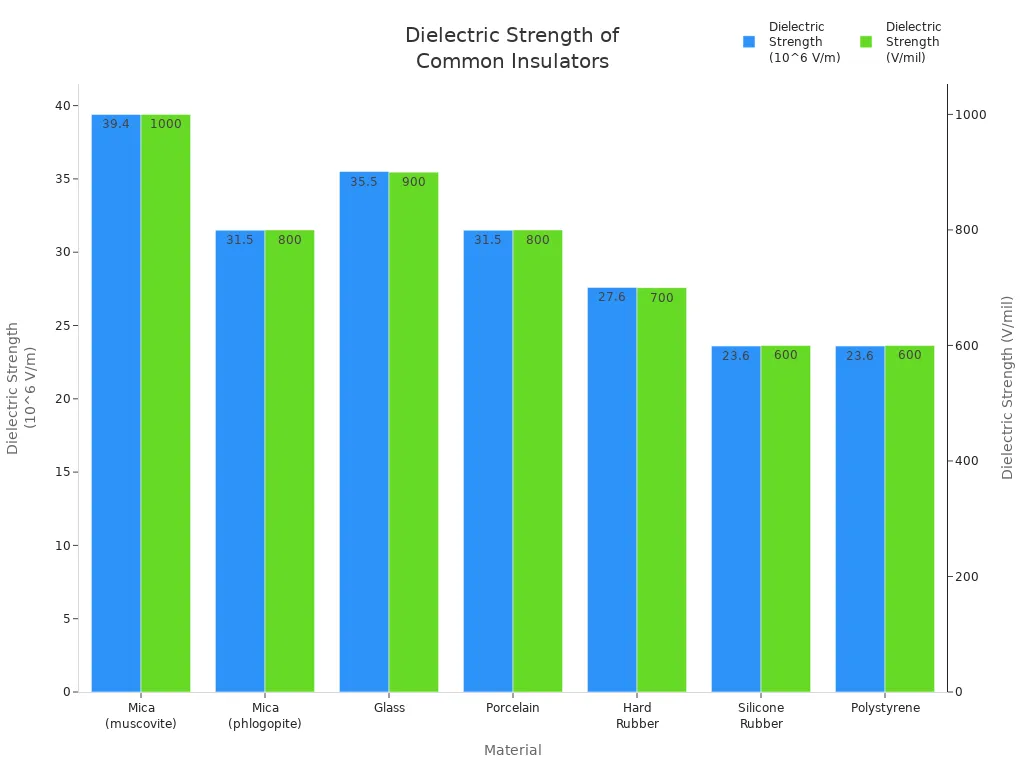

Mica stands out as one of the best natural electrical insulators. Its , which means it can withstand very strong electric fields without breaking down. This property makes mica more reliable than many other common insulating materials. For example, muscovite mica has a dielectric strength of , which is higher than glass, porcelain, and several types of rubber. The table below shows how mica compares to other materials:

| Material | Dielectric Strength (10^6 V/m) | Dielectric Strength (V/mil) |

|---|---|---|

| Mica (muscovite) | 39.4 | 1000 |

| Mica (phlogopite) | 31.5 | 800 |

| Glass | 35.5 | 900 |

| Porcelain | 31.5 | 800 |

| Hard Rubber | 27.6 | 700 |

| Silicone Rubber | 23.6 | 600 |

| Polystyrene | 23.6 | 600 |

Mica’s high dielectric strength, combined with its thermal stability and chemical resistance, allows it to perform well in high-voltage and high-temperature environments. These qualities make mica a top choice for many applications of mica in the electrical industry.

Industrial Uses

Manufacturers use mica in because it resists electrical breakdown and maintains its properties under stress. In electric motors, , which helps prevent electrical faults and improves safety. Capacitors use mica as a safely and reliably. High-voltage cables and switchgear equipment also rely on mica sheets to prevent leakage and ensure safe operation.

The electrical and electronic industries use several forms of mica, including . in motors and transformers, providing insulation that stands up to high temperatures and voltages. to fit specific components, making it useful in capacitors, transformers, and electrical panels. Mica tubes protect cables and heating elements, offering both durability and flexibility.

Tip: The applications of mica in electrical insulation help protect equipment from electrical discharges and overheating, making devices safer and more efficient.

2. Thermal Insulation

Heat Resistance

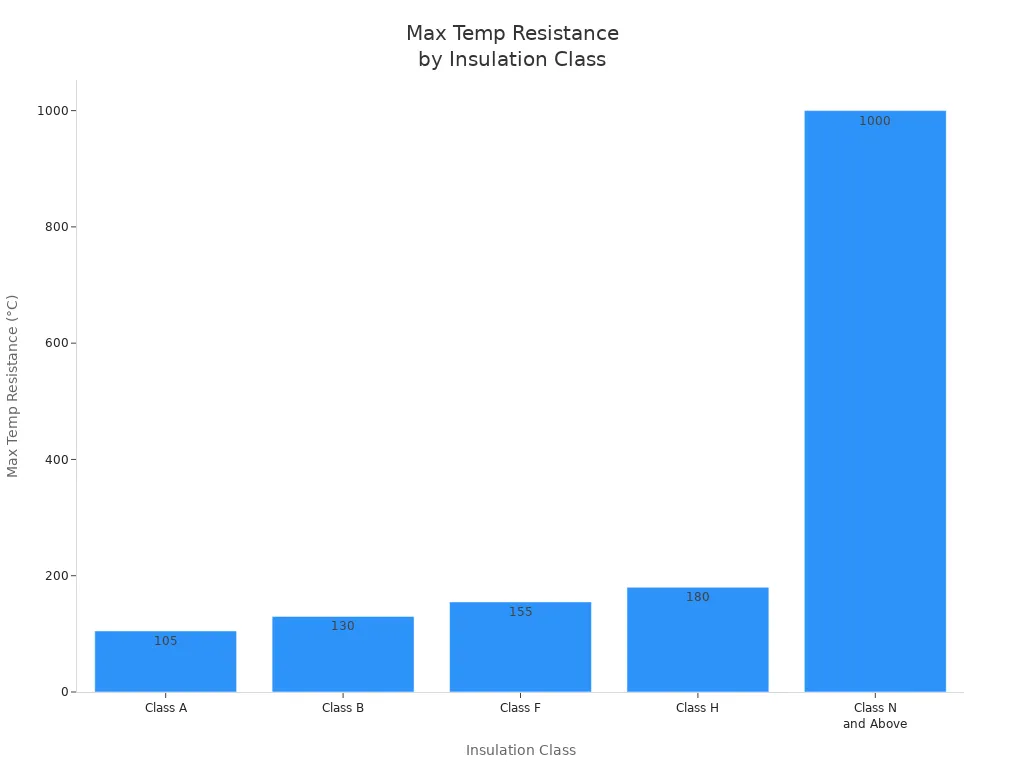

Mica stands out as a top performer in thermal insulation due to its ability to withstand extreme temperatures. . This level of heat resistance surpasses many other common insulation materials. The following table compares the :

| Insulation Material | Maximum Service Temperature |

|---|---|

| Calcium Silicate | Approximately 649°C |

| Fibrous Glass | Approximately 482°C |

| Mica (Phlogopite) | Up to 1000°C |

Mica not only resists high temperatures but also maintains its structure and insulating properties over time. This makes it a reliable choice for environments where both heat and electrical insulation are critical. The chart below highlights how mica’s :

Applications of Mica

Industries choose mica for thermal insulation in settings where safety and performance matter most. , kilns, and incinerators. and shield themselves from intense heat. Power plants and nuclear reactors use mica to protect equipment and maintain efficiency during high-temperature operations.

Mica’s nonflammable and nontoxic nature makes it ideal for fire-prone industries. Electrical manufacturers use mica in heating elements, transformers, and high-voltage cables to ensure safe operation even under extreme heat. The defense sector uses mica for fireproofing in passenger cabins, tank interiors, and missile systems. Automotive and aerospace engineers select mica for components exposed to both heat and electrical stress.

Note: The applications of mica in thermal insulation help industries achieve both safety and energy efficiency, even in the harshest environments.

3. Refractory Materials

Metallurgical Uses

Mica plays a crucial role in the production of refractory bricks and furnace linings. Manufacturers add mica to these materials to improve their flexibility and durability. In induction furnace linings, mica acts as a . This feature allows the lining to expand and contract during heating and cooling cycles without cracking. As a result, the ceramic lining stays protected, and maintenance becomes easier because the lining can be removed without damaging the furnace structure.

Mica’s adaptability stands out in the variety of sizes and temperature grades available for lining materials. These options help protect furnace coils and extend the life of furnace linings. Mica also provides , which keeps heat inside the furnace and improves energy efficiency. Its electrical insulation properties make it an essential ingredient in insulating firebricks, ceramic fiber blankets, ropes, and tapes. These products help industrial furnaces, kilns, and foundries operate safely and efficiently.

Note: Mica-infused refractory materials help reduce downtime and maintenance costs, making them a smart choice for heavy industry.

High-Temperature Performance

Mica’s stability at high temperatures makes it indispensable in metallurgical processes. Phlogopite mica, in particular, maintains its structure and performance at temperatures . Its unique crystalline structure, rich in magnesium, iron, and aluminum silicates, gives it exceptional thermal stability. This allows mica to withstand rapid temperature changes without cracking or breaking apart.

Mica’s low thermal conductivity and resistance to thermal shock protect equipment from sudden heat spikes. Its chemical stability means it , which helps prevent corrosion in harsh environments. Metallurgical plants use mica sheets and gaskets to insulate heating elements, electrodes, and arc protection components. These applications keep equipment safe from heat and electrical damage, extending service life and improving operational safety.

| Mica Type | Max Temperature | Key Benefit |

|---|---|---|

| Muscovite | Up to 700°C | Good insulation |

| Phlogopite | Above 1000°C | Superior thermal stability |

Mica’s unique combination of flexibility, heat resistance, and chemical inertness makes it a top choice for high-temperature industrial applications.

4. New energy vehicles

Insulation Components

Automotive engineers rely on mica for a wide range of insulation components. Mica’s unique properties make it a preferred material in both traditional and electric vehicles. Its high dielectric strength and heat resistance help protect sensitive systems from electrical faults and extreme temperatures. that use mica and their specific functions:

| Insulation Component Type | Specific Function(s) |

|---|---|

| Mica Sheets | Electrical insulation to prevent shorts and failures, ensuring longevity and reliability of electrical systems. |

| Heat Shielding Components | Protect sensitive parts from high engine and exhaust temperatures, maintaining optimal system temperatures. |

| Mica-based Gaskets and Washers | Provide sealing under high temperature and pressure to prevent fluid leakage, enhancing durability. |

| Flame Retardant Barriers | Slow the spread of fire, improving vehicle safety, especially critical in electric vehicles. |

| Thermal Insulation around Battery Packs | Thermal management and electrical isolation in electric vehicles, protecting battery systems. |

| Custom Seals and Spacers | Mechanical durability and electrical insulation in starters, alternators, turbo gaskets, and other components. |

. Mica-based barriers and spacers also appear in chargers, EV stations, and thermal battery systems. These components help vehicles operate safely and efficiently under demanding conditions.

Safety and Efficiency

Mica enhances both safety and efficiency in automotive systems. Its outstanding dielectric strength insulates electrical cables, preventing shocks and short circuits. Mica’s thermal resistance allows gaskets and brake linings to withstand high temperatures, reducing the risk of overheating and system failure. In electric vehicles, mica provides thermal management and electrical isolation for battery packs, which improves battery efficiency and extends lifespan.

in harsh automotive environments. It resists vibration, abrasion, and corrosion, helping maintain system integrity. The following list summarizes mica’s key contributions to automotive safety and efficiency:

, preventing electrical hazards.

High thermal resistance ensures components maintain performance at elevated temperatures.

Mica’s lightweight and durable nature simplifies installation and reduces maintenance needs.

Efficient insulation reduces power loss and heat transfer, boosting energy efficiency.

Chemical stability protects against corrosion, supporting long-term reliability.

Tip: Mica’s unique combination of electrical and thermal properties makes it essential for modern automotive design, especially as vehicles become more electrified and safety standards rise.

5. Aerospace

Heat and Electrical Insulation

Mica plays a vital role in aerospace engineering due to its unique combination of properties. Engineers select mica for its ability to withstand extreme temperatures and provide reliable electrical insulation. The material’s natural fire resistance and lightweight structure make it ideal for demanding aerospace environments.

Mica offers , protecting critical components from intense heat in aircraft and spacecraft.

Its excellent electrical insulation safeguards sensitive avionics and control systems from electromagnetic interference.

The material acts as a flame barrier, enhancing safety in both aircraft interiors and exteriors.

Mica’s durability and low weight meet the strict requirements for aerospace insulation materials.

The layered structure of mica provides shock resistance, which is especially important in military and high-performance aerospace applications.

Mica serves as a dielectric in radar and communication equipment, improving signal accuracy and blocking unwanted interference.

Engineers use mica in thermal insulation for airframes, propulsion systems, battery packs, flight recorders, and electrical systems in .

Note: Mica’s help maintain the stability and longevity of aerospace equipment, even under extreme conditions.

Performance in Aircraft

Aircraft components face harsh environments, including rapid temperature changes, high pressure, and exposure to chemicals. Mica enhances the performance and reliability of these components in several ways.

Mica provides exceptional thermal insulation for heat shields, thrust reversers, and engine gaskets, protecting them from .

The material acts as a fire and flame retardant barrier, improving safety for passengers and crew.

Mica ensures the insulation of flight recorders, preserving critical data during emergencies.

It offers robust protection for battery systems, supporting safe and reliable power management.

Mica-based insulation shields avionics and engine parts from electrical interference and heat damage.

The chemical inertness of mica allows it to resist harsh chemicals and moisture, maintaining performance in challenging conditions.

Lightweight mica solutions reduce overall aircraft weight while maintaining structural strength and durability.

Aircraft manufacturers trust mica for its proven track record in . Its ability to absorb thermal stress, resist degradation, and comply with strict industry standards makes it a cornerstone of modern aerospace design.

FAQ

What makes mica different from other insulating materials?

Mica offers high dielectric strength, heat resistance, and chemical stability. These properties allow mica to perform in harsh environments where many other materials fail. Engineers choose mica for its reliability in both electrical and thermal insulation.

Can mica withstand exposure to chemicals?

Yes. Mica resists acids, alkalis, and most solvents. This chemical stability makes mica suitable for use in industries where materials face harsh or corrosive conditions. Mica maintains its structure and performance over time.

Is mica safe for use in consumer products?

Mica is non-toxic and non-flammable. Manufacturers use mica in paints, cosmetics, and appliances. Safety standards require testing, and mica meets these requirements in approved applications.

How does mica improve the durability of construction materials?

Mica strengthens cement, plaster, and joint compounds. Its platy structure fills gaps and prevents cracks. Builders use mica to create smoother, longer-lasting surfaces in walls and floors.

Where can companies source industrial-grade mica?

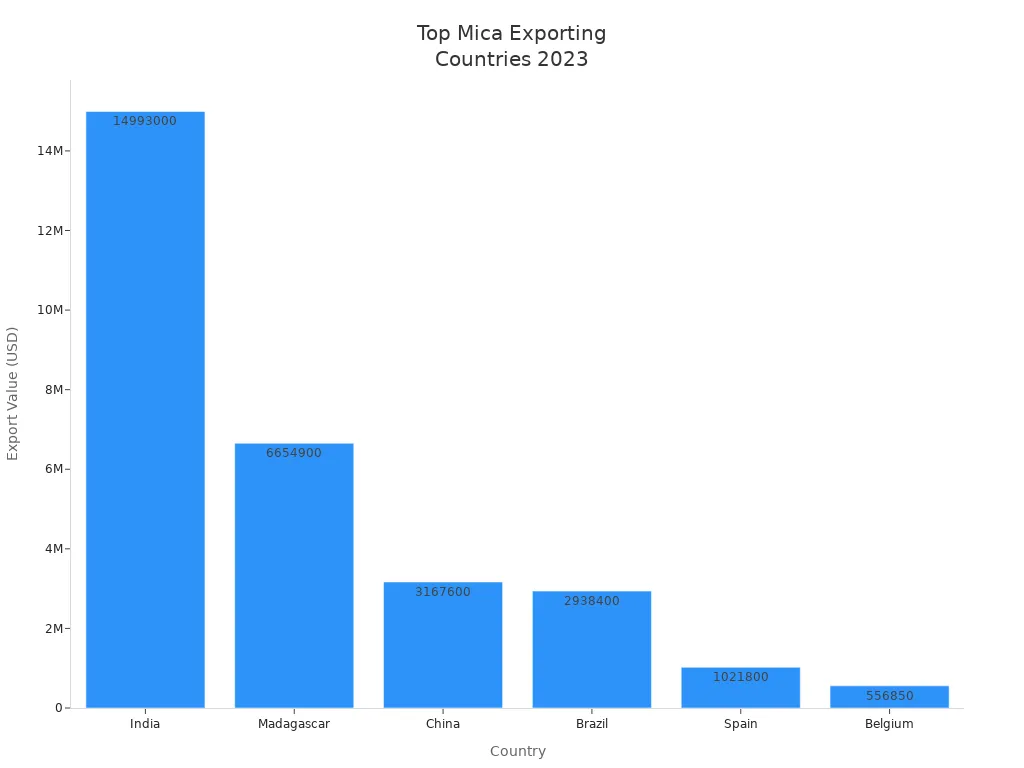

Companies can source mica from major producers in India, China, Madagascar, and Brazil. Suppliers offer mica in various forms, such as sheets, flakes, and powders, to meet different industrial needs.

Previous Page

Next Page