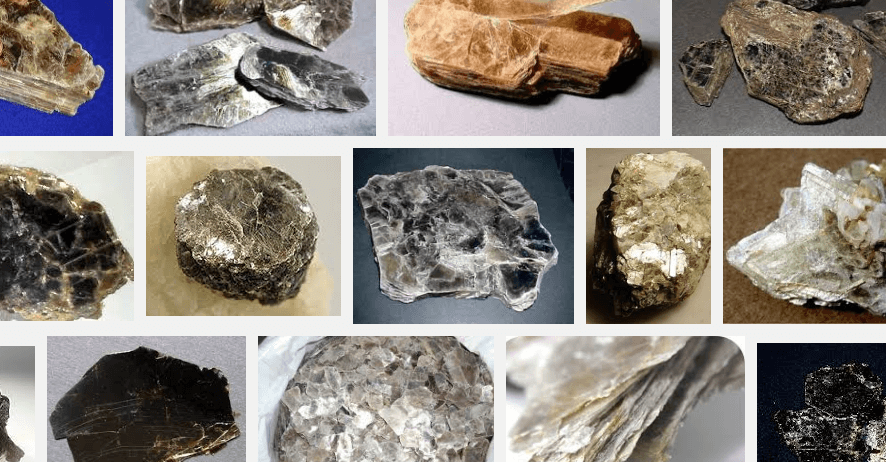

muscovite

Mica: Commonly Asked Questions

Key Takeaways:

When engineers encounter mica for the first time, questions flood in. What makes this mineral so special? Why do industries choose it over synthetic alternatives? How safe is it to handle? These questions reflect the growing interest in understanding one of nature's most versatile materials.

Mica has quietly powered modern technology for over a century, yet many professionals remain unfamiliar with its unique capabilities. From electrical insulation in power plants to heat shields in spacecraft, this remarkable mineral continues proving its worth across diverse applications.

This comprehensive mica FAQ addresses the most pressing questions about this fascinating material. Whether you're selecting materials for electrical equipment, exploring heat-resistant options, or investigating sustainable alternatives, you'll find the answers you need to make informed decisions.

What Is Mica and Where Does It Come From?

Mica represents a group of naturally occurring silicate minerals distinguished by their layered crystal structure. The name derives from the Latin word "micare," meaning "to shine," reflecting the mineral's characteristic lustrous appearance.

The two primary industrial types are muscovite (white mica) and phlogopite (brown mica). Muscovite dominates electrical applications due to its superior dielectric properties, while phlogopite excels in high-temperature environments thanks to its enhanced thermal stability.

Geologically, mica forms in igneous and metamorphic rocks through complex crystallization processes spanning millions of years. This natural formation creates the distinctive layered structure that gives mica its unique properties. The mineral's ability to split into incredibly thin, flexible sheets while maintaining structural integrity sets it apart from other materials.

Major mica deposits exist worldwide, with India, China, Brazil, and Madagascar leading production. Each region produces slightly different characteristics based on local geological conditions, affecting color, purity, and specific performance attributes.

How Does Mica Differ From Synthetic Insulating Materials?

The fundamental difference lies in mica's natural crystalline structure versus the manufactured composition of synthetic alternatives. This natural arrangement provides inherent stability that synthetic materials often struggle to match.

Temperature performance showcases mica's superiority dramatically. While many synthetic insulators begin degrading at 200-300°C, mica maintains its properties at temperatures exceeding 500°C continuously. Some grades withstand short-term exposure to temperatures over 1000°C without structural failure.

Chemical stability represents another key advantage. Mica resists degradation from acids, alkalis, and organic solvents that destroy synthetic materials over time. This chemical inertness ensures consistent performance throughout extended service life.

Electrical properties also favor mica significantly. Its dielectric strength typically ranges from 2,000 to 4,000 volts per millimeter, substantially higher than most synthetic options. The material's low dielectric loss factor ensures minimal energy waste in electrical applications.

Longevity differs markedly as well. Properly installed mica components often outlast the equipment they protect, while synthetic materials may require replacement multiple times during equipment life cycles.

What Are the Main Industrial Types of Mica?

Muscovite mica dominates electrical and electronics applications. Its light color, excellent dielectric properties, and superior electrical insulation make it ideal for capacitors, transformers, and precision instruments. The material's stability at high voltages ensures reliable performance in critical electrical systems.

Phlogopite mica serves high-temperature applications where muscovite might prove inadequate. Its darker color reflects a different mineral composition that provides enhanced thermal stability. This makes phlogopite valuable for heating elements, furnace insulation, and automotive applications where extreme heat resistance is essential.

Synthetic mica offers an engineered alternative created under controlled laboratory conditions. While providing consistent properties and eliminating natural variations, synthetic mica typically costs significantly more than natural varieties. It may not match natural mica's long-term stability or unique combination of properties.

Mica composites combine natural mica with binding agents to create sheets and formed parts. These materials balance mica's natural properties with improved mechanical characteristics, making them suitable for applications requiring both electrical performance and structural integrity.

Is Mica Safe to Handle and Work With?

Natural mica poses minimal health risks when handled properly. Unlike asbestos, which shares some visual similarities, mica's crystal structure and chemical composition create no significant respiratory hazards under normal conditions.

However, like any mineral dust, fine mica particles shouldn't be inhaled in large quantities. Industrial safety protocols recommend dust masks when cutting, grinding, or processing mica materials. Proper ventilation and dust collection systems minimize exposure risks in manufacturing environments.

Mica's chemical inertness means it doesn't react with skin or most substances, making handling relatively safe. The material won't release toxic gases when heated, unlike some synthetic alternatives that may emit harmful vapors at elevated temperatures.

Food-grade mica applications demonstrate its safety profile. When properly processed and certified, mica can contact food products without contamination concerns. Medical device applications also utilize mica where biocompatibility is essential.

Proper storage and handling procedures focus primarily on preventing material damage rather than safety concerns. Keeping mica dry and protected from contamination maintains its electrical properties while preventing degradation.

Which Industries Rely Most Heavily on Mica?

Electrical and electronics industries consume the largest volumes of mica globally. Power generation equipment, including transformers, generators, and switchgear, depends on mica insulation for safe, reliable operation. The semiconductor industry uses ultra-pure mica for specialized applications requiring exceptional electrical properties.

Automotive manufacturing incorporates mica in numerous applications. Heating elements for seat warmers, window defrosters, and cabin heating systems rely on mica's thermal properties. Electrical insulation in engine compartments must withstand extreme temperatures while maintaining electrical integrity.

Aerospace and defense applications demand materials performing reliably under extreme conditions. Mica's resistance to radiation, temperature fluctuations, and chemical exposure makes it suitable for satellite components, missile guidance systems, and aircraft electrical systems.

Industrial manufacturing uses mica across diverse applications. Furnace insulation, heating element supports, and high-temperature gaskets all benefit from mica's unique property combination. Glass manufacturing particularly values mica's ability to withstand molten glass temperatures without contamination.

Construction and building materials incorporate mica in fire-resistant coatings, thermal insulation, and specialty concrete applications. Its natural flame resistance enhances building safety while providing thermal barrier properties.

How Long Does Mica Last in Real-World Applications?

Mica's exceptional longevity stems from its stable crystalline structure and resistance to environmental degradation factors. Properly installed mica components regularly achieve service lives of 30-50 years or more in electrical applications.

Power transformers with mica insulation often operate for decades without insulation-related failures. The material's resistance to thermal cycling, which destroys many synthetic materials through expansion and contraction stress, contributes significantly to this longevity.

Environmental factors that degrade other materials have minimal impact on mica. UV radiation, ozone exposure, and chemical atmospheres that cause synthetic materials to break down leave mica largely unaffected.

However, mechanical abuse can damage mica prematurely. Impact, excessive vibration, or improper installation techniques may cause cracking or delamination. Proper installation and protection from mechanical stress ensure optimal service life.

Regular maintenance and inspection help identify potential issues before they become critical. Visual examination can detect developing problems, allowing preventive action to maintain system reliability.

Can Mica Be Recycled or Reprocessed?

Mica recycling presents unique challenges and opportunities. Clean mica waste from manufacturing processes can often be reprocessed into lower-grade applications where premium electrical properties aren't required.

Ground mica from recycled sources finds valuable use in paints, coatings, and plastic fillers. These secondary applications maintain material value while reducing waste disposal requirements. The cosmetics industry also uses recycled mica for various formulations.

Recovery from decommissioned electrical equipment faces contamination challenges. Oil-impregnated insulation and other contaminants may limit reuse options, though specialized cleaning processes can sometimes restore usability.

Economic factors influence recycling viability significantly. High-grade electrical mica commands premium prices, making recycling economically attractive for clean materials. Lower-grade applications may not justify recycling costs.

Environmental considerations drive increased interest in mica recycling. As sustainability concerns grow, manufacturers seek ways to minimize waste and extend material lifecycles through innovative recycling approaches.

What Factors Influence Mica Quality and Pricing?

Visual inspection reveals much about mica quality. Clear, unblemished sheets with uniform thickness and minimal inclusions indicate higher grades suitable for demanding electrical applications. Discoloration, spots, or irregular surfaces suggest lower quality materials.

Laboratory testing quantifies critical properties. Dielectric strength measurements, thermal stability tests, and mechanical property evaluations ensure materials meet specific application requirements. These tests form the basis for quality certification and grade classification.

Geological source significantly impacts quality characteristics. Some deposits produce consistently higher-grade materials, while others yield variable quality requiring careful sorting and processing. Mining techniques also affect final product quality.

Market dynamics drive pricing fluctuations. Supply disruptions in major producing regions can cause significant price increases, particularly for high-grade electrical materials. Demand from electronics manufacturing influences pricing for premium grades.

Processing costs contribute substantially to final pricing. Higher-grade materials require more extensive processing, sorting, and quality control, increasing production costs. Transportation from remote mining locations also affects pricing.

How Should Mica Materials Be Stored and Handled?

Proper storage maintains mica quality and performance characteristics. Dry conditions prevent moisture absorption that could affect electrical properties, particularly in humid environments. Controlled humidity storage facilities ensure optimal material condition.

Temperature control during storage isn't critical for mica itself, but extreme temperature changes can affect packaging materials and create condensation issues. Stable storage temperatures prevent handling difficulties and material damage.

Handling procedures should minimize mechanical stress that could cause cracking or delamination. Appropriate lifting equipment, padded storage surfaces, and careful transportation prevent damage during material movement.

Contamination prevention protects electrical properties and ensures material suitability for critical applications. Clean storage areas, covered materials, and proper handling procedures prevent contamination from oils, chemicals, or other substances.

Inventory rotation ensures materials maintain optimal condition. First-in, first-out practices prevent extended storage that might allow degradation or require retesting before use.

What Are the Most Common Mica Misconceptions?

Many people confuse mica with asbestos due to superficial visual similarities in some forms. However, mica's crystal structure and chemical composition differ completely from asbestos minerals. Mica doesn't pose the same health risks associated with asbestos exposure.

Some assume synthetic alternatives always outperform natural materials. While synthetics offer consistency and controlled properties, they rarely match natural mica's unique combination of electrical, thermal, and mechanical characteristics, particularly over extended service periods.

The misconception that mica is inherently fragile stems from observing thin natural sheets. While individual layers are delicate, properly processed mica products offer excellent mechanical strength and durability for their intended applications.

Previous Page