How to Manufacture Mica Parts: A Complete Guide

Key Takeaways:

Manufacturing mica parts requires precision, expertise, and understanding of this unique mineral's properties. From electrical insulators to heat-resistant components, mica parts serve critical functions across industries. This comprehensive guide walks you through every step of the manufacturing process, from raw material preparation to final quality control.

Understanding the complete manufacturing workflow helps engineers specify the right processes for their applications and ensures optimal part performance. Whether you need thin insulation sheets or complex shaped components, proper manufacturing techniques make all the difference.

Understanding Raw Mica Materials

Before diving into manufacturing processes, it's essential to understand the starting materials. Natural mica comes in various forms, with muscovite and phlogopite being the most common for industrial applications. Each type offers different properties that affect manufacturing approaches.

Raw mica arrives as large sheets or flakes that must be processed into usable forms. The quality of raw material directly impacts the final product's performance, so careful selection and inspection are crucial first steps in any manufacturing operation.

Manufacturers typically sort raw mica by size, thickness, and quality grade. Higher-grade materials command premium prices but deliver superior electrical and thermal properties in finished parts.

Preparing Mica for Manufacturing

The first manufacturing step involves cleaning and preparing raw mica materials. This process removes impurities, foreign materials, and damaged sections that could compromise final part quality.

Cleaning typically involves dry brushing or air blasting to remove loose particles without damaging the delicate mica structure. Some applications require washing with deionized water, followed by careful drying to prevent delamination.

After cleaning, manufacturers sort mica by thickness and quality grades. This sorting ensures consistent properties within each production batch and helps optimize cutting and forming processes.

Creating Mica Sheets and Composites

Many mica parts start as engineered sheets created through specialized bonding processes. This involves combining mica paper or flakes with binding agents to create uniform, workable materials.

The bonding process uses high-temperature silicone resins or other specialized adhesives applied uniformly across mica layers. These materials are then compressed under hydraulic pressure while being heated to specific temperatures, typically between 150-200°C.

This hard-pressing technique, combined with controlled heat application, creates composite sheets with consistent thickness and improved mechanical properties. The resulting material maintains mica's excellent electrical and thermal characteristics while offering better workability for subsequent manufacturing steps.

Cutting and Shaping Techniques

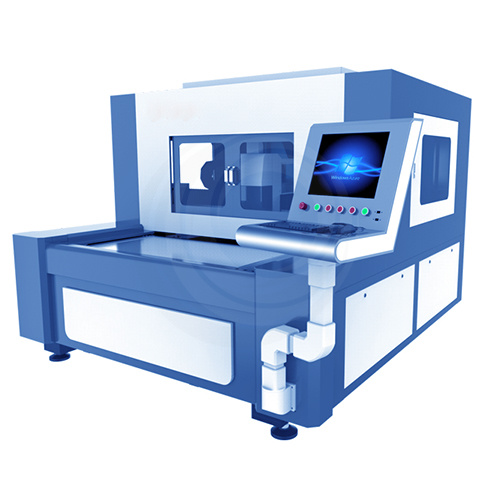

Modern mica parts manufacturing employs various cutting and shaping technologies, each suited to different applications and precision requirements. The choice of cutting method depends on part complexity, thickness, and required tolerances.

Water Jet Cutting

Water jet cutting offers exceptional precision for complex mica parts. This process uses high-pressure water streams to cut through mica materials without generating heat that could damage the mineral structure. Water jet cutting works particularly well for intricate shapes and tight tolerances.

The cold cutting process preserves mica's natural properties and produces smooth, precise edges. However, proper drying after water jet cutting is essential to prevent moisture-related issues in electrical applications.

Laser Cutting

Laser cutting provides high precision and excellent edge quality for thinner mica materials. This thermal cutting process requires careful parameter control to prevent overheating and preserve mica's structure.

Modern laser systems offer programmable cutting patterns, making them ideal for complex shapes and small production runs. The process produces minimal waste and allows for tight nesting of parts to optimize material usage.

Dry Milling

Traditional dry milling uses rotating cutting tools to shape mica parts. This mechanical cutting method works well for thicker materials and simpler geometries. Proper tool selection and cutting parameters are essential to prevent chipping or delamination.

Dry milling typically requires multiple passes for complex shapes, with careful attention to cutting speeds and feed rates. The process generates dust that requires proper collection and disposal.

Stamping and Punching

For high-volume production of simple shapes, stamping and punching offer cost-effective manufacturing solutions. These processes use precision dies to cut mica materials quickly and consistently.

Die design is critical for successful stamping operations. Sharp, well-maintained cutting edges minimize material distortion and ensure clean cuts. Regular die maintenance prevents quality issues and extends tooling life.

Precision Machining Operations

Some mica parts require additional machining operations beyond basic cutting. These may include drilling, threading, or surface finishing to meet specific application requirements.

Drilling mica requires specialized techniques to prevent cracking or chipping. Sharp drill bits, controlled feed rates, and proper support backing help ensure clean holes without material damage. For threading operations, careful tap selection and lubrication prevent material fracture.

Surface finishing may involve sanding, grinding, or polishing to achieve required surface quality or dimensional accuracy. These operations must be performed carefully to avoid removing too much material or damaging mica's structure.

Quality Control and Testing

Comprehensive quality control ensures manufactured mica parts meet specifications and performance requirements. This involves both dimensional inspection and performance testing.

Dimensional inspection uses precision measuring equipment to verify part geometry, thickness, and tolerances. Surface quality inspection checks for cracks, delamination, or other defects that could affect performance.

Performance testing may include dielectric strength testing, thermal cycling, and mechanical stress testing, depending on the intended application. These tests verify that parts will perform reliably under actual operating conditions.

Assembly and Secondary Operations

Many mica parts require assembly or secondary operations before final delivery. This might include bonding multiple components, installing mounting hardware, or applying protective coatings.

Assembly operations require careful handling to prevent damage to delicate mica components. Proper fixtures and handling procedures ensure parts maintain their integrity throughout the assembly process.

Secondary operations like coating application or marking must be compatible with mica's properties and intended operating environment.

Best Practices for Mica Parts Manufacturing

Successful mica parts manufacturing requires attention to detail throughout every process step. Key best practices include maintaining clean work environments, using appropriate handling procedures, and implementing robust quality control systems.

Storage conditions for both raw materials and finished parts significantly impact quality. Mica materials should be kept dry and protected from contamination that could affect electrical properties.

Previous Page

Next Page