Discover Mica Minerals: Comprehensive Guide to Properties and Applications

Mica minerals represent a distinct group of silicate minerals characterized by their unique layered crystal structure and exceptional physical properties. These naturally occurring minerals have established themselves as essential components across multiple industrial sectors, from electrical applications to cosmetics manufacturing. Understanding the fundamental characteristics, applications, and handling requirements of mica minerals is crucial for professionals seeking to optimize their material selection processes.

This comprehensive examination provides detailed specifications, application parameters, and operational considerations necessary for effective mica mineral utilization. The following sections present structured analysis of key properties, implementation protocols, and technical requirements essential for informed decision-making in mica mineral applications.

Key Properties and Specifications

Mica minerals exhibit distinct physical and chemical characteristics that determine their suitability for specific applications. The primary properties include:

Physical Properties:

Crystal structure: Layered silicate formation with perfect basal cleavage

Hardness rating: 2-3 on Mohs scale

Density range: 2.7-3.2 g/cm³

Dielectric strength: 20-200 kV/mm

Temperature resistance: Up to 600°C for muscovite, 1000°C for phlogopite

Chemical Composition:

Mica minerals contain varying concentrations of aluminum, potassium, magnesium, and iron silicates. The chemical formula varies by mica type:

Muscovite: KAl₂(AlSi₃O₁₀)(OH)₂

Phlogopite: KMg₃(AlSi₃O₁₀)(OH)₂

Biotite: K(Mg,Fe)₃(AlSi₃O₁₀)(OH)₂

Electrical Properties:

High dielectric constant

Excellent insulation characteristics

Low power loss factor

Stable electrical properties across temperature ranges

Critical Considerations and Handling Protocols

Proper handling and storage of mica minerals require adherence to established protocols to maintain material integrity and performance characteristics.

Storage Requirements:

Maintain ambient temperature between 15-25°C

Relative humidity levels below 65%

Protection from direct sunlight and moisture exposure

Sealed container storage to prevent contamination

Processing Considerations:

Mechanical processing must account for natural cleavage planes

Grinding operations require controlled environments to prevent moisture absorption

Quality control measures must monitor particle size distribution

Contamination prevention protocols during material transfer

Safety Specifications:

Personal protective equipment requirements for dust exposure prevention

Ventilation systems for processing areas

Material safety data sheet compliance

Regular air quality monitoring in work environments

Technical Tips for Optimal Performance

Implementation of best practices ensures maximum efficiency and performance in mica mineral applications:

Size Classification Optimization:

Select appropriate mesh sizes based on specific application requirements. Standard classifications include 20-40 mesh, 40-60 mesh, and 60-100 mesh grades for different performance specifications.

Purity Assessment:

Conduct regular purity analysis using X-ray diffraction methods to verify mineral composition and identify potential contaminants that may affect performance characteristics.

Processing Parameter Control:

Maintain consistent grinding parameters including speed, temperature, and duration to achieve uniform particle size distribution and preserve material properties.

Quality Assurance Protocols:

Implement systematic testing procedures for electrical properties, thermal stability, and mechanical characteristics to ensure compliance with application specifications.

Distinctive Characteristics and Performance Attributes

Mica minerals demonstrate exceptional performance attributes that distinguish them from alternative materials:

Thermal Stability:

Superior heat resistance enables applications in high-temperature environments where organic materials would degrade. This property is particularly valuable in electrical insulation applications requiring extended operational life.

Mechanical Properties:

The unique layered structure provides excellent flexibility while maintaining structural integrity. This characteristic allows for formation into complex shapes without compromising performance.

Chemical Inertness:

Resistance to chemical degradation ensures long-term stability in aggressive environments. This property makes mica suitable for applications involving exposure to acids, alkalis, and organic solvents.

Optical Properties:

Transparency and optical clarity in thin sheets enable specialized applications in optical instruments and decorative materials.

Industrial Applications and Use Cases

Mica minerals serve essential functions across diverse industrial sectors:

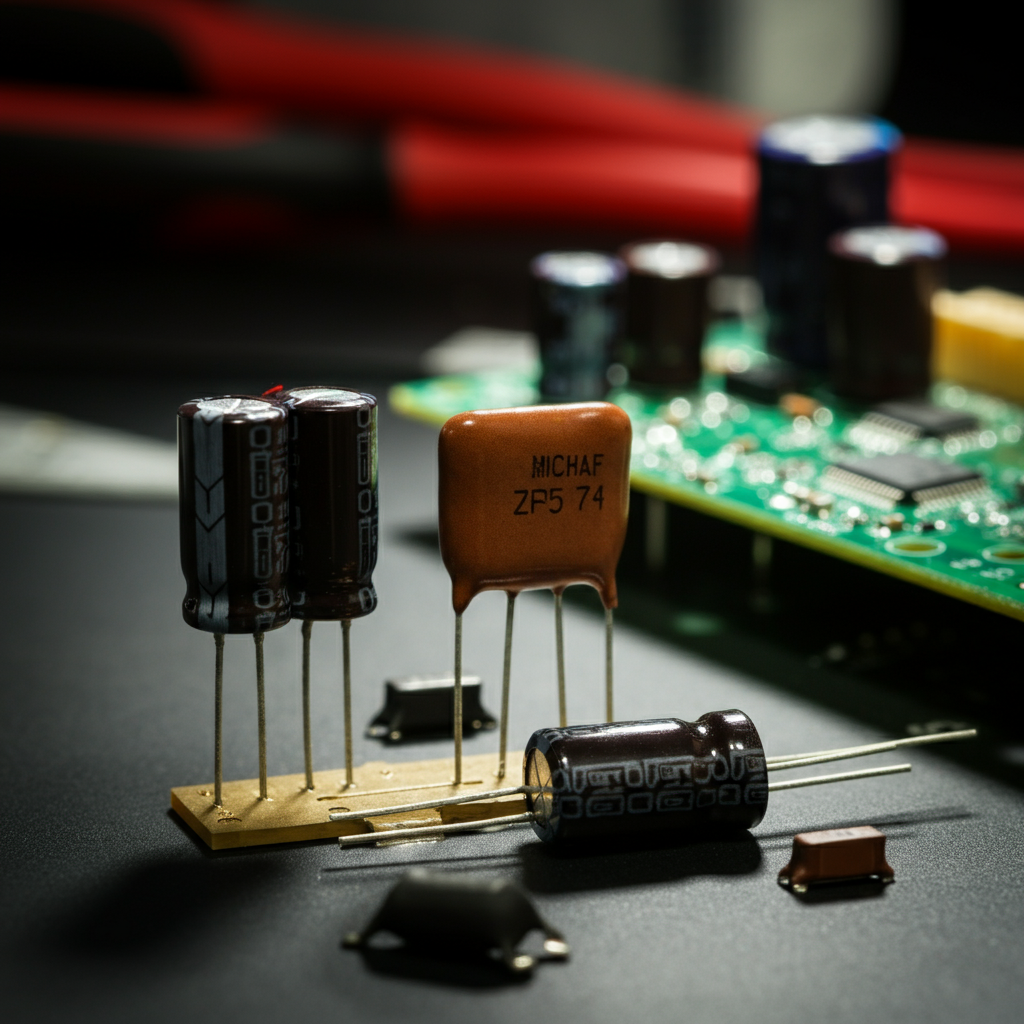

Electrical and Electronics Industry:

High-voltage insulation systems

Capacitor dielectrics

Electronic component substrates

Cable insulation materials

Construction and Building Materials:

Fire-resistant coatings

Decorative concrete additives

Roofing materials

Thermal barrier applications

Automotive Sector:

Brake pad formulations

Sound dampening materials

Heat-resistant gaskets

Electrical system insulation

Cosmetics and Personal Care:

Pearlescent pigments

Foundation formulations

Eye shadow applications

Skin care products

Frequently Asked Questions

What factors determine mica grade selection for specific applications?

Grade selection depends on particle size requirements, purity levels, electrical properties, and thermal performance specifications. Applications requiring high dielectric strength necessitate premium grades with minimal impurities.

How does moisture content affect mica performance?

Moisture absorption can significantly reduce electrical insulation properties and thermal stability. Maintaining low moisture content through proper storage and handling protocols is essential for optimal performance.

What quality control measures ensure consistent mica mineral properties?

Regular testing protocols include particle size analysis, chemical composition verification, electrical property assessment, and thermal stability evaluation. These measures ensure compliance with specified performance parameters.

Are there environmental considerations for mica mineral applications?

Mica minerals are naturally occurring and chemically inert, making them environmentally compatible. However, processing operations require dust control measures and proper waste management protocols.

Partner with Mica Mineral Specialists

Successful implementation of mica minerals in industrial applications requires technical expertise and reliable supply chain management. Professional consultation ensures optimal material selection, proper handling procedures, and performance optimization.

For detailed specifications, custom formulations, and technical support regarding mica mineral applications, contact certified mineral specialists who can provide comprehensive analysis of your specific requirements and recommend appropriate solutions based on proven performance data and industry standards.

Previous Page

Next Page