What is mica?

Mica is a general term for a group of layered aluminosilicate minerals. Its main components are silicate compounds of metals such as potassium, aluminum, magnesium, iron, and lithium. Its unique crystal structure gives it excellent insulation, heat resistance, and peelability. It can be peeled into extremely thin, elastic sheets and is widely used in electronics, building materials, cosmetics, and other industrial fields. According to its source and production method, mica is mainly divided into Natural mica and Synthetic mica

Main Types and Properties

Natural mica can be divided into several varieties according to its chemical composition and color. The most widely used in industry include:

Muscovite :Colorless and transparent or light-colored, with a chemical formula of KAl₂(AlSi₃O₁₀)(OH,F)₂, it has excellent electrical insulation and heat resistance (continuous use temperature 550℃), Mohs hardness 2-2.5, density 2.76g/cm³. The main production areas are Altay, Xinjiang, and Danba, Sichuan, China.

Phlogopite :Yellow, brown, or dark brown, with a chemical formula of KMg₃(AlSi₃O₁₀)(F,OH)₂, it has better heat resistance than muscovite (continuous use temperature 850℃), density 2.78-2.85g/cm³, mainly produced in Tuguiwula, Inner Mongolia, and Canada.

Biotite :Black due to its high iron content, it has poor chemical stability and is mainly used to refine vermiculite as a heat-insulating material.

Lepidolite :A light purple mica containing lithium, it is an important mineral raw material for extracting lithium.

Formation and Distribution

Natural mica is formed through magma crystallization, metamorphism, or feldspar alteration, mainly found in pegmatites and gneisses. Global high-quality mica deposits are concentrated in India (accounting for 60% of production), Brazil, Russia, and China 。China's mica resources are mainly distributed in Xinjiang (accounting for 67% of the national reserves), Sichuan, and Inner Mongolia, with the main deposit type being granite pegmatite.

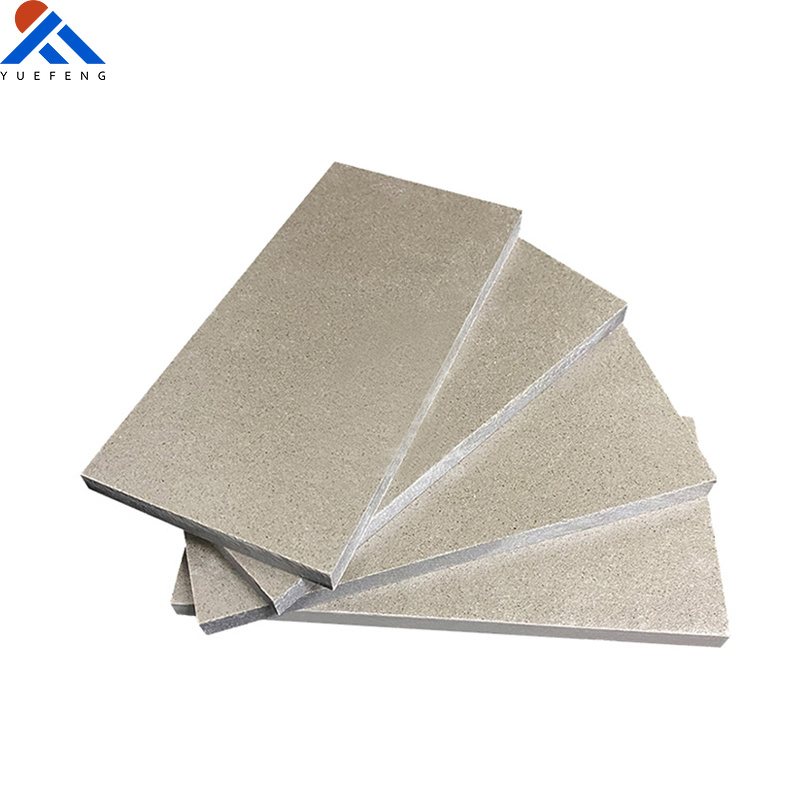

Production Process and Properties

Synthetic mica (also known as fluorophlogopite) is prepared by high-temperature melting method ,melting electrofused magnesia, potassium fluorosilicate, and other raw materials in a 1450-1600℃ electric furnace, and controlling the cooling crystallization. Its chemical formula is KMg₃AlSi₃O₁₀F₂, and the key difference from natural mica is:

Purity :Impurity content <0.2%, very low iron content, whiteness can reach more than 92%.

Heat Resistance :Continuous use temperature 1200℃, short-term temperature resistance 1600℃, far exceeding natural mica.

Insulation Performance :Volume resistivity is 1000 times higher than natural mica at high temperatures, dielectric strength reaches 150-200kV/cm.

Chemical Stability :Resistant to strong acids and alkalis (pH 1-14), insoluble in water and organic solvents.

Application Field Expansion

New Energy :Lithium battery separator coating material (improved thermal runaway protection), photovoltaic panel backsheet insulation layer (weather resistance improved by 25%).

High-end Cosmetics :Replacing natural mica used in brands such as Dior and Lancôme, avoiding the risk of heavy metal residue, and complying with the EU REACH standard.

Aerospace :High-temperature resistant window materials for satellites, insulating gaskets for rocket engines, withstanding extreme temperature differences from -270℃ to 1200℃.

Special Ceramics

Conclusion

Recommended news