Calcined mica paper

Product Category:

Mica Paper

Keywords:

Yuefeng Mica

- Description

-

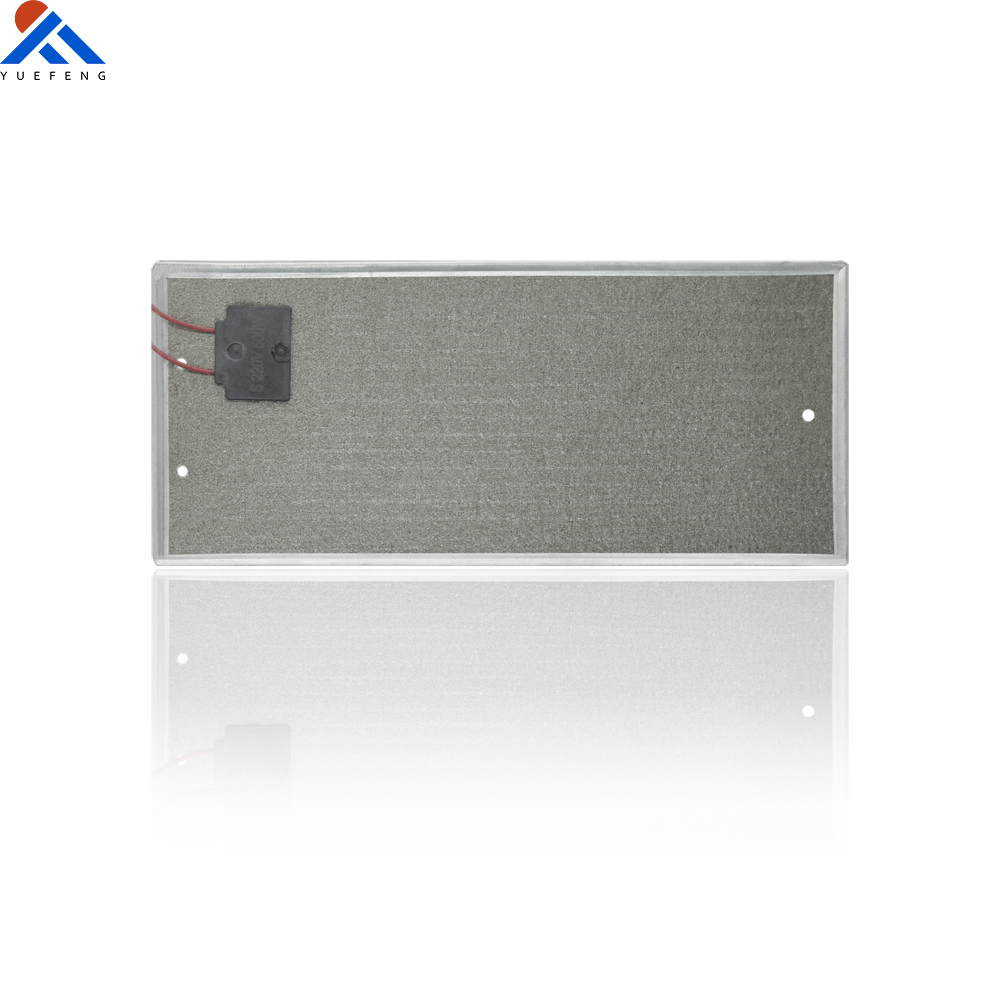

- Commodity name: Calcined mica paper

Product Overview

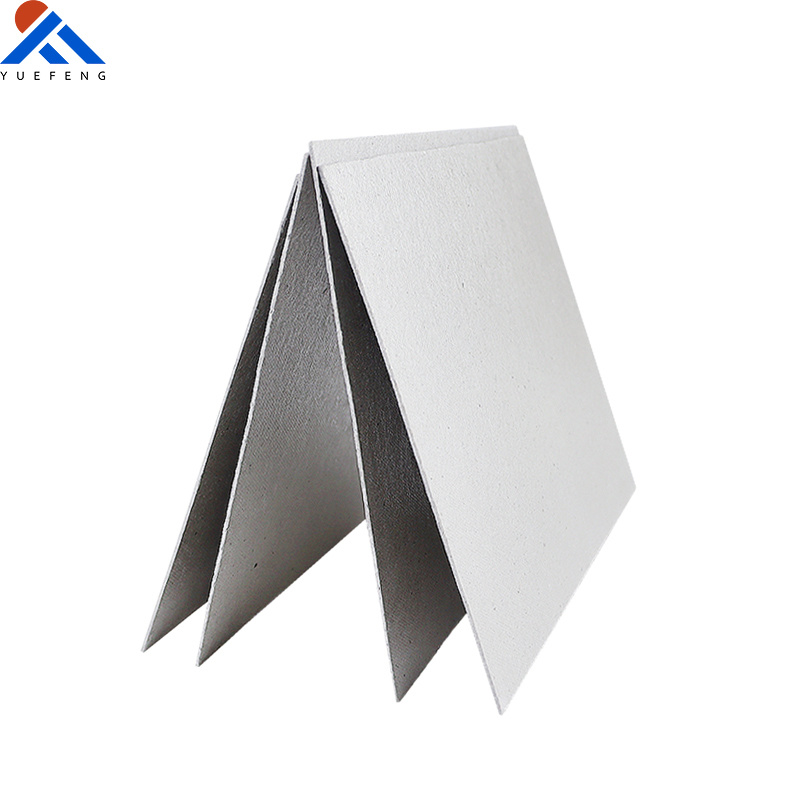

Calcined mica paper is a sophisticated insulation material crafted through the thermal processing of mica to enhance its structure and performance. The calcination process removes any organic content or impurities, resulting in a denser, more durable material with improved thermal stability and superior insulation properties. Engineered for high-demand industrial applications, calcined mica paper provides reliable protection against extreme temperatures, electrical discharges, and mechanical stresses.

With its outstanding resilience and versatility, calcined mica paper is the insulation material of choice for industries seeking durability, efficiency, and precision.

Key Features

Thermal Stability

Withstands continuous exposure to temperatures exceeding 1000°C, retaining its integrity even in harsh environments.

Enhanced Electrical Insulation

Offers excellent dielectric strength, minimizing risks of electrical breakdown in high-voltage systems.

Improved Mechanical Durability

Calcined mica paper’s densified construction ensures exceptional wear resistance and dimensional stability.

Non-Combustible and Fire-Resistant

Provides high levels of safety in applications requiring flame retardance.

Chemical and Moisture Resistance

Performs reliably even when exposed to oils, solvents, and humid conditions, making it ideal for diverse industrial environments.

Applications

Calcined mica paper excels in a broad spectrum of high-performance applications, including but not limited to:

Electrical Insulation in High-Voltage Systems

Used in generators, transformers, and motors to ensure safe and consistent insulation under demanding conditions.

Thermal Barriers in Furnaces and Industrial Ovens

Acts as a protective lining or barrier against excessive heat, improving equipment efficiency and durability.

Fire-Resistant Components

Key element in fire-resistant cables, ensuring operational continuity of critical systems during emergencies.

Aerospace and Defense

Provides heat shielding and insulation for high-performance components, ensuring reliability and safety.

Petrochemical and Manufacturing Industries

Insulates sensitive equipment exposed to extreme temperature fluctuations and aggressive chemicals.

Benefits at a Glance

Reliable performance under high-temperature and high-voltage conditions.

Reduced risk of electrical and thermal failures, enhancing operational safety.

Durable composition minimizes replacement and maintenance costs over time.

Versatile material adapts to diverse industrial needs and specifications.

Eco-friendly and compliant with industry safety and environmental standards.

Specifications

Material: High-purity calcined mica

Temperature Resistance: Over 1000°C

Thickness Range: Customizable based on application

Format: Supplied as sheets or rolls for easy integration into various systems

Technical Parameters:

Nominal Value (g/m²) Average Tolerance (%) Individual Tolerance (%) Air Permeability (S/100ml) Permeation Time (Time) Water Extract Conductivity (μS/cm) Mass Loss (%) Tensile Strength (N/cm) Dielectric Strength (KV/mm) 50 ±3 ±5 ≤900 ≤20 15 0.5 ≥3 ≥24 60 ±3 ±5 ≤1000 ≤25 15 0.5 ≥3.2 ≥24 70 ±3 ±5 ≤1100 ≤30 15 0.5 ≥3.3 ≥24 100 ±3 ±5 ≤2100 ≤55 15 0.5 ≥3.9 ≥26 120 ±3 ±5 ≤3000 ≤65 15 0.5 ≥4.0 ≥26 160 ±3 ±5 ≤3500 ≤90 15 0.5 ≥6.0 ≥26 Call to Action

Recommended Products