Mica paper

Product Category:

Mica Paper

Keywords:

Yuefeng Mica

- Description

-

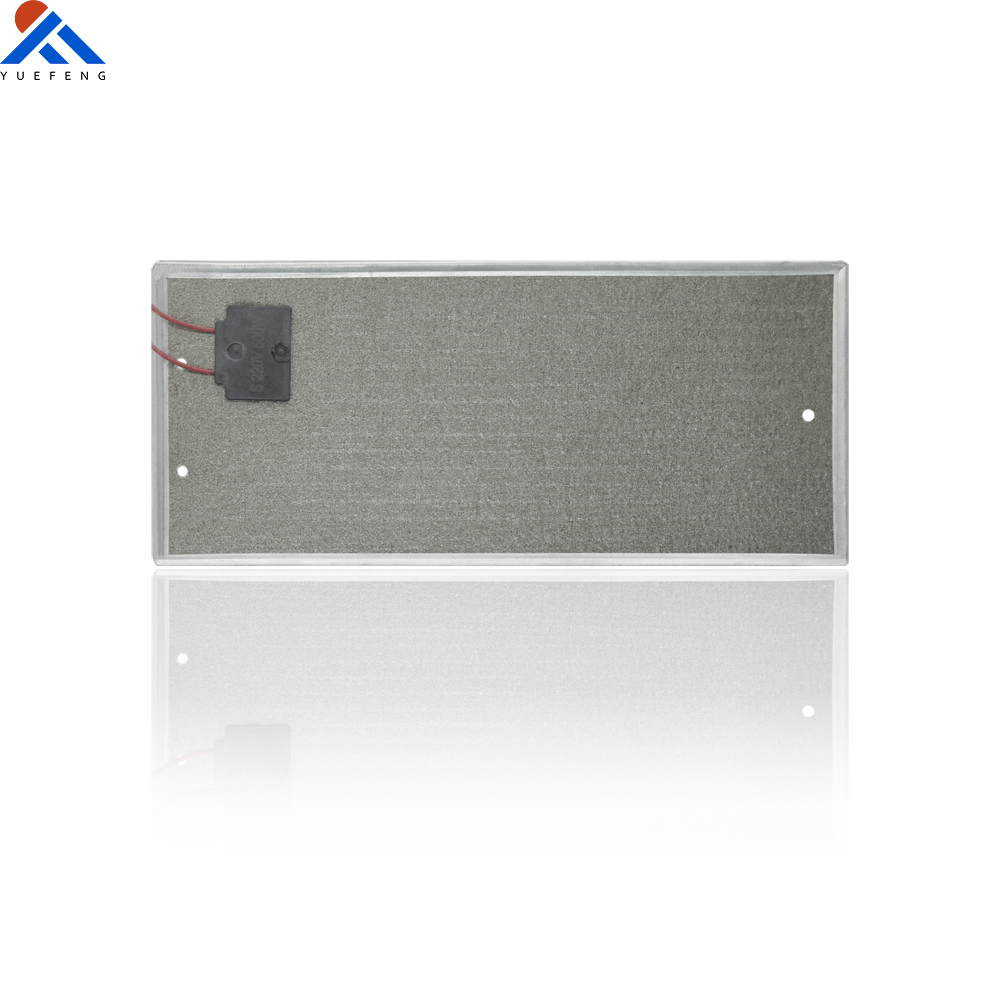

- Commodity name: Mica paper

RAW MATERIALElectrical Grade Mica Paper (Muscovite & Phlogopite)

Premium reconstituted mica paper manufactured by hydraulic separation. Designed as the core substrate for mica tapes, sheets, and laminates. Offers excellent permeability for resin impregnation.

- ✓ High Dielectric Strength (> 20kV/mm)

- ✓ Uniform Tensile Strength

- ✓ Available in Rolls (Width: 900-1040mm)

Product Overview

Our Mica Paper is produced using high-quality natural mica scraps (Muscovite or Phlogopite). Through a specialized hydro-pulping process, the mica is broken down into flakes and reconstituted into a continuous paper sheet without the use of chemical binders.

This process ensures a highly porous structure, making it ideal for impregnation with silicone or epoxy resins. It serves as the base material for manufacturing fire-resistant mica tapes, rigid mica sheets, and heating elements.

Excellent Impregnability

High air permeability allows resins to penetrate fully, creating strong bonds in laminated products.

Voltage Resistance

Exceptional corona resistance and breakdown voltage, ensuring safety in high-voltage motors.

Thermal Stability

Muscovite maintains integrity up to 500°C, while Phlogopite withstands up to 1000°C.

Technical Specifications

Properties Muscovite Paper (Standard) Phlogopite Paper (High Temp) Basis Weight (g/m²) 50 - 160 g/m² 80 - 250 g/m² Tensile Strength (N/10mm) ≥ 4.0 ≥ 2.0 Penetration (s/100ml) ≤ 80 ≤ 70 Dielectric Strength (kV/mm) ≥ 20 ≥ 16 Standard Width 960mm / 1000mm / 1040mm (Slitting Available) Frequently Asked Questions about Mica Paper

What is mica paper used for? +

Mica paper is primarily used as an electrical and thermal insulation material. It is commonly found in high-voltage motors, generators, transformers, and cables. It is often reinforced with glass fiber and resin to create mica tapes or rigid sheets for industrial furnaces and aerospace applications.Is mica paper electrically conductive? +

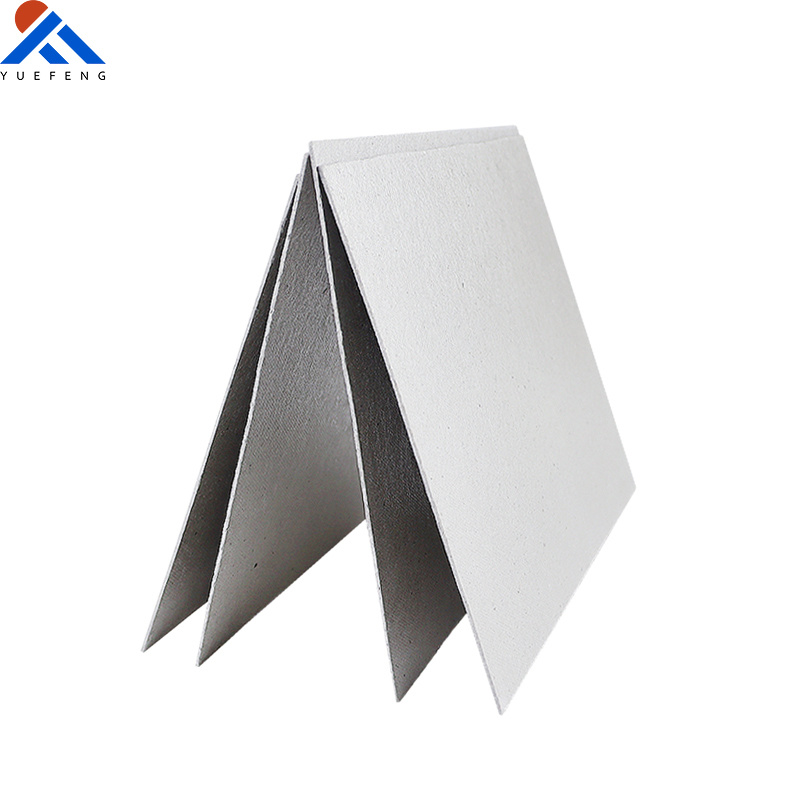

No, mica paper is an excellent electrical insulator (dielectric). It has high dielectric strength, typically exceeding 20 kV/mm, which allows it to prevent the flow of electricity and protect equipment from short circuits and electrical breakdown.What is the difference between mica paper and mica sheet? +

Mica paper is the raw material made from reconstituted mica flakes, similar to how pulp makes paper. It is thin and fragile on its own. Mica sheet is the finished product made by stacking layers of mica paper, impregnating them with resin (like silicone or epoxy), and pressing them under heat to form rigid or flexible boards.How is mica paper manufactured? +

Mica paper is produced by a process called "reconstitution." High-quality natural mica scraps are heated (calcined) and then crushed into tiny flakes using high-pressure water jets (hydro-pulping). This mica pulp is then processed on a specialized Fourdrinier paper machine to form a continuous, uniform sheet of pure mica paper without any binders.What temperature can mica paper withstand? +

The temperature resistance depends on the mineral type. Muscovite mica paper can withstand temperatures up to approximately 500°C (932°F). Phlogopite mica paper has higher thermal stability and can withstand continuous temperatures up to 1000°C (1832°F).What is the difference between Muscovite and Phlogopite mica paper? +

Muscovite (White Mica) is known for its superior electrical properties, transparency, and mechanical strength, but has a lower temperature limit (500°C). Phlogopite (Green/Gold Mica) is softer but offers superior heat resistance (up to 1000°C), making it ideal for high-heat applications like furnace linings and fire-resistant cables.Is mica paper hazardous to health? +

Finished mica paper products are generally non-hazardous. However, during manufacturing or machining (cutting/drilling), mica dust can be generated. Inhaling fine mica dust over long periods can be harmful to the lungs. Proper ventilation and dust masks are recommended when working with mica mechanically.Is mica paper waterproof? +

Pure mica paper has low water absorption but is not entirely waterproof due to its layered structure. However, when impregnated with resins (like silicone or epoxy) to create mica sheets or tapes, it becomes highly moisture-resistant and suitable for humid environments.How do you cut mica paper? +

Raw mica paper is very fragile and can be cut with standard paper cutting tools. However, reinforced mica sheets or laminates require more robust tools. Thin sheets can be cut with shears or utility knives, while thicker rigid sheets often require band saws, laser cutters, or CNC machines to prevent delamination.Why is mica paper used in electrical insulation? +

It is used because of its unique combination of properties: high dielectric strength (prevents arcing), high thermal resistance (does not melt or burn), and excellent chemical stability. It ensures the safety and longevity of electrical systems even under extreme stress and heat.

Recommended Products