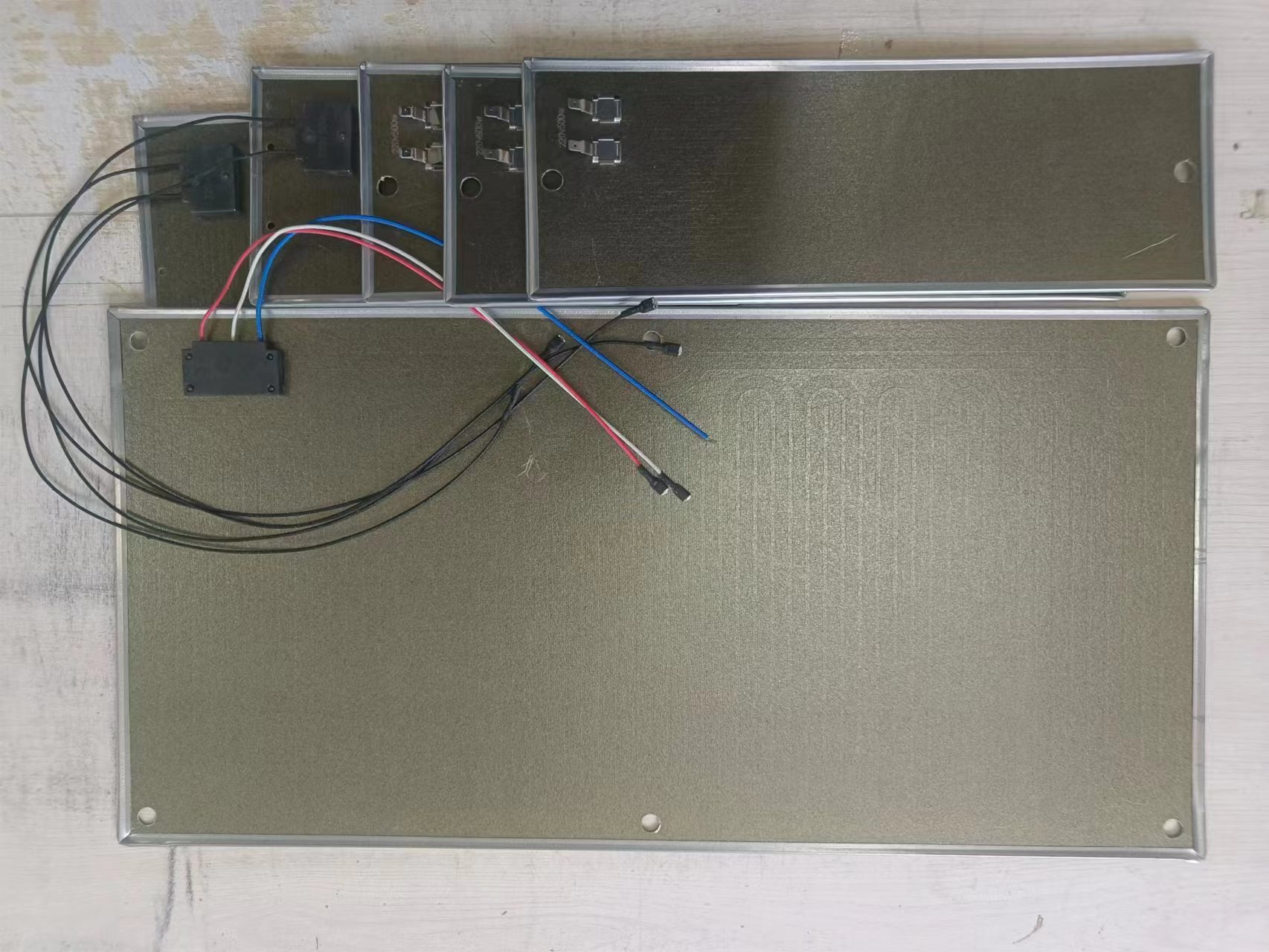

Mica heating component

Mica heating components are functional assemblies made by fixing or embedding heating elements such as resistance wires and electric heating films with mica materials as insulating substrates.

They combine the excellent insulation and high-temperature resistance of mica (long-term service temperature can reach above 500℃) with the efficient heating capacity of heating elements, featuring uniform heating, high heat conversion efficiency and stable safety performance.

They are widely used in household appliances (such as electric irons, ovens), industrial heating equipment, medical instruments and other fields to provide stable heat output for equipment.

Product Category:

Heating Film

Keywords:

Yuefeng Mica

- Description

-

- Commodity name: Mica heating component

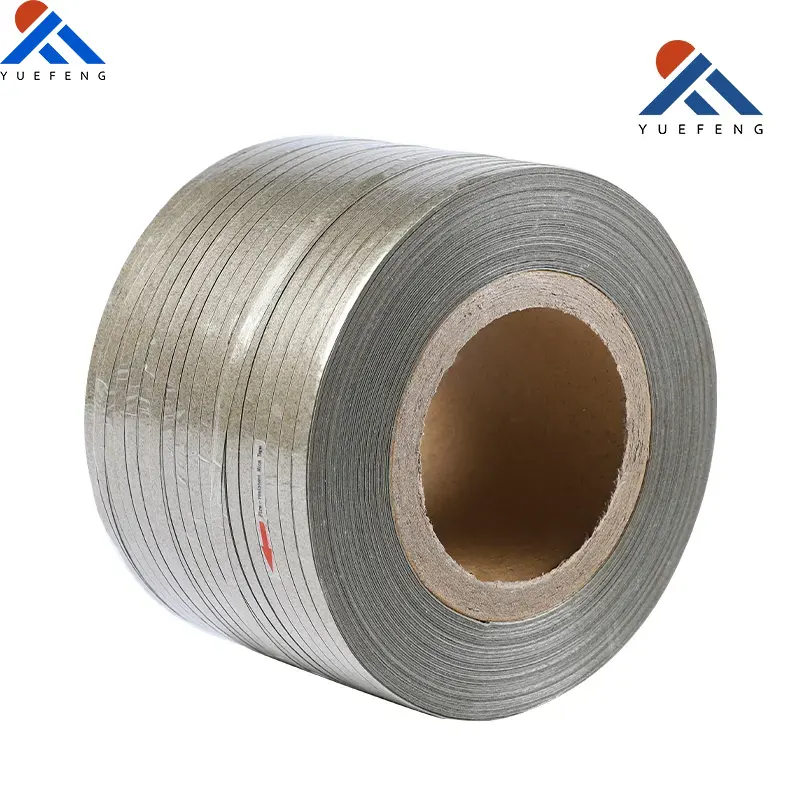

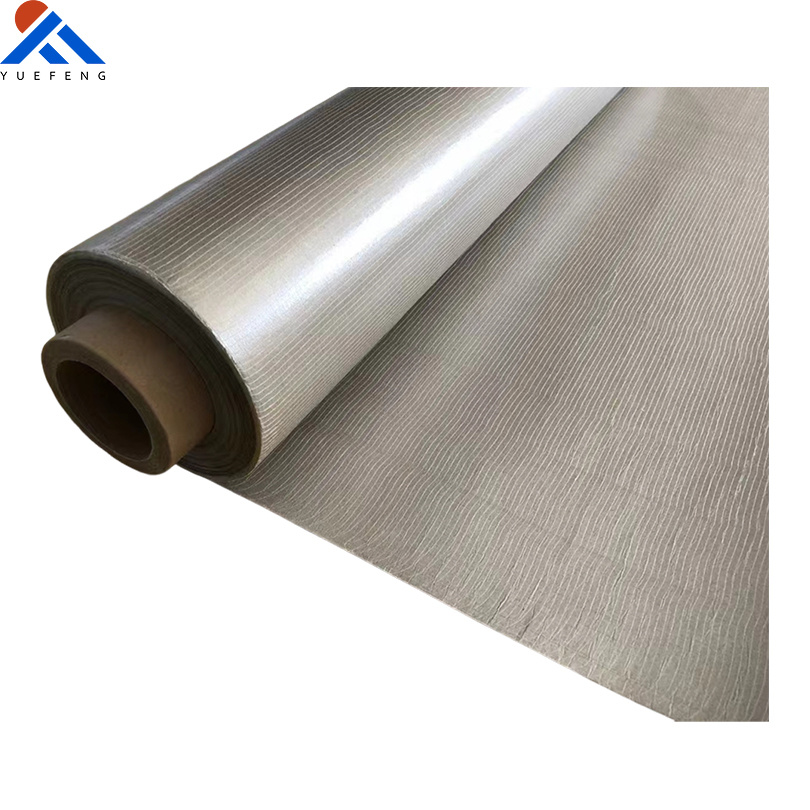

Mica heating components are composite heating devices that organically combine heating elements with mica substrates. Their structure usually consists of mica plates (or mica paper) as the insulating framework, with resistance wires, electric heating sheets, carbon fiber heating elements and other core heating units embedded or attached inside. Some products are also equipped with leads, terminals and protective shells to ensure safety during installation and use.The performance advantages of this component are very prominent: Firstly, relying on the excellent electrical insulation of mica materials (breakdown voltage ≥ 10kV/mm), it can effectively isolate the heating element from external metal parts and avoid the risk of electric leakage; Secondly, it has significant high-temperature resistance, which can work stably in a wide temperature range from -20℃ to 500℃, with short-term tolerance up to 600℃ or more, and extremely low thermal shrinkage; Thirdly, the heat conduction efficiency is high. The thermal conductivity of mica is moderate, and with the uniform arrangement of heating elements, it can achieve rapid temperature rise and uniform heat diffusion, with a thermal response time usually within 3-5 seconds; In addition, it has good mechanical strength, excellent anti-vibration and anti-impact performance, a service life of more than 5000 hours, and strong chemical stability, which is not easily affected by humid, acid and alkali environments.In terms of application fields, mica heating components are widely used in household and industrial equipment: In household scenarios, the heating modules of electric irons, hair dryers, heaters, microwave ovens and other electrical appliances mostly use such components; In industrial production, it is a key heating component of plastic molding molds, medical equipment (such as hot compress instruments), food processing machinery, and laboratory constant temperature devices; In the agricultural field, it can also be used in the constant temperature heating system for greenhouse seedling raising.

Recommended Products