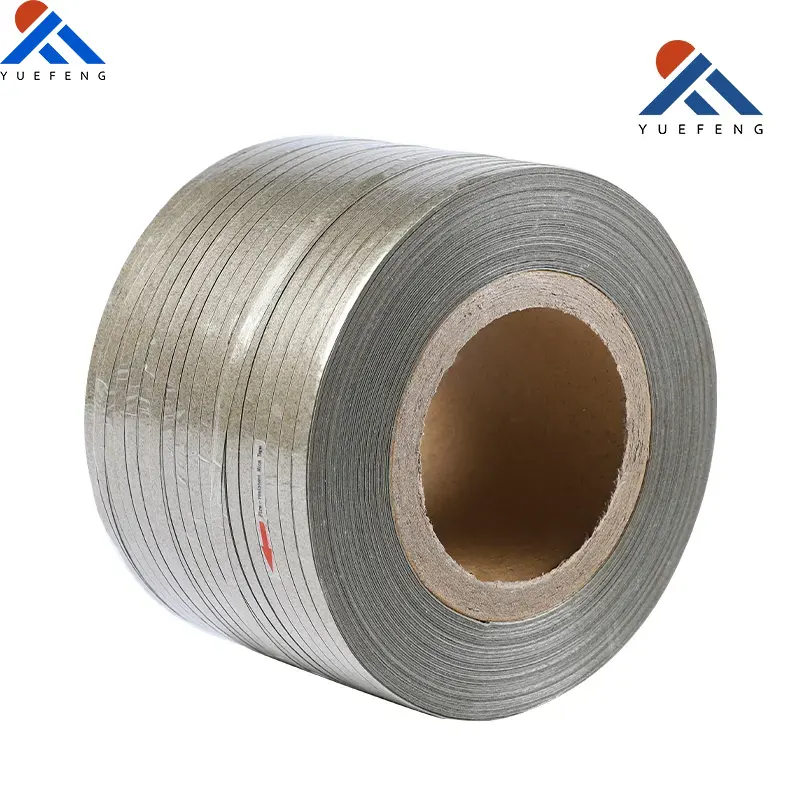

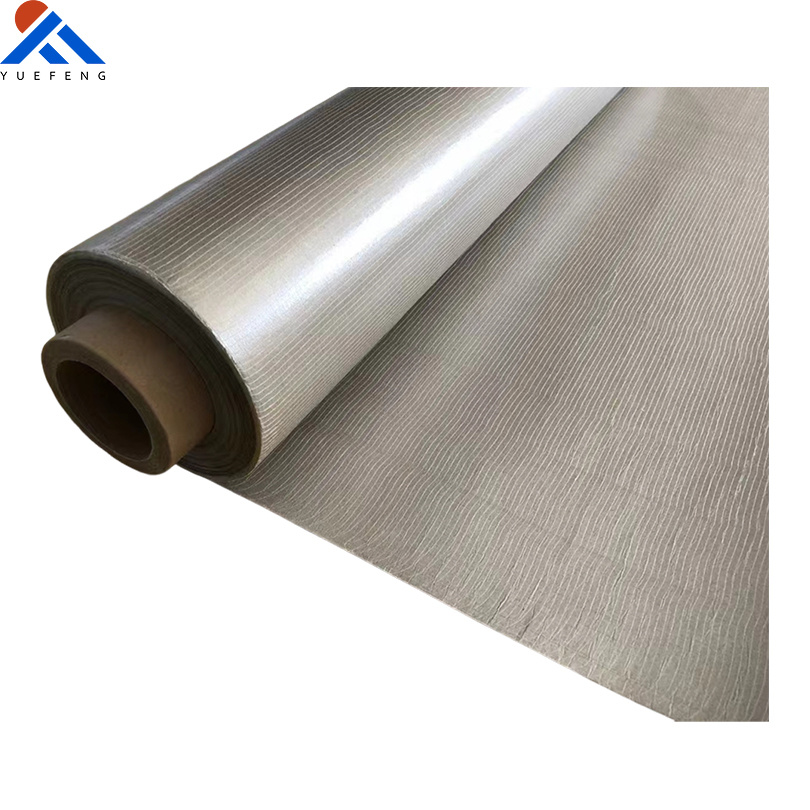

Mica Paper

Product Category:

Mica Paper

Keywords:

Yuefeng Mica

- Description

-

- Commodity name: Mica Paper

Key Types of Mica Paper

1. Muscovite Mica Paper

-

Source: Derived from natural muscovite mica (aluminum-rich).

-

Core Properties

-

Dielectric strength: 15-28 kV/mm.

-

Continuous operating temperature: 400-500°C (short-term: 600°C).

-

Cost-effective with high availability.

-

-

Best For: Low to medium-voltage electrical equipment (motors, transformers), household appliances, and construction wiring.

2. Phlogopite Mica Paper

-

Source: Made from natural phlogopite mica (magnesium-rich).

-

Core Properties

-

Dielectric strength: 12-25 kV/mm.

-

Continuous operating temperature: 600-700°C (short-term: 800°C).

-

Superior resistance to high heat and mild alkalis.

-

-

Best For: High-temperature industrial furnaces, metallurgy equipment, and aerospace engine insulation.

3. Synthetic Mica Paper

-

Source: Artificial fluorophlogopite mica (lab-synthesized).

-

Core Properties

-

Dielectric strength: 25-40 kV/mm.

-

Continuous operating temperature: Up to 1000°C.

-

Ultra-pure (99%+ mica content) with minimal impurities.

-

-

Best For: High-precision applications (nuclear reactors, advanced electronics, and aerospace components) requiring extreme reliability.

4. Calcined Mica Paper

-

Source: Processed from natural or synthetic mica via high-temperature calcination (800-1000°C).

-

Core Properties

-

Dielectric strength: 20-35 kV/mm.

-

Continuous operating temperature: 600-900°C.

-

Enhanced thermal stability (moisture and volatile-free).

-

-

Best For: Industrial kilns, exhaust systems, and solar thermal equipment exposed to prolonged high heat.

Why Mica Paper?

Across all types, mica paper delivers unmatched “insulation + heat resistance” duality, outperforming materials like fiberglass or plastic films in harsh environments. Its flexibility allows use in tight spaces (e.g., coil windings, furnace linings), while its compatibility with adhesives and resins enables integration into composite insulation systems. Choosing the right type depends on temperature requirements, voltage levels, and cost—whether for everyday electrical devices or extreme aerospace conditions, mica paper offers a tailored solution.

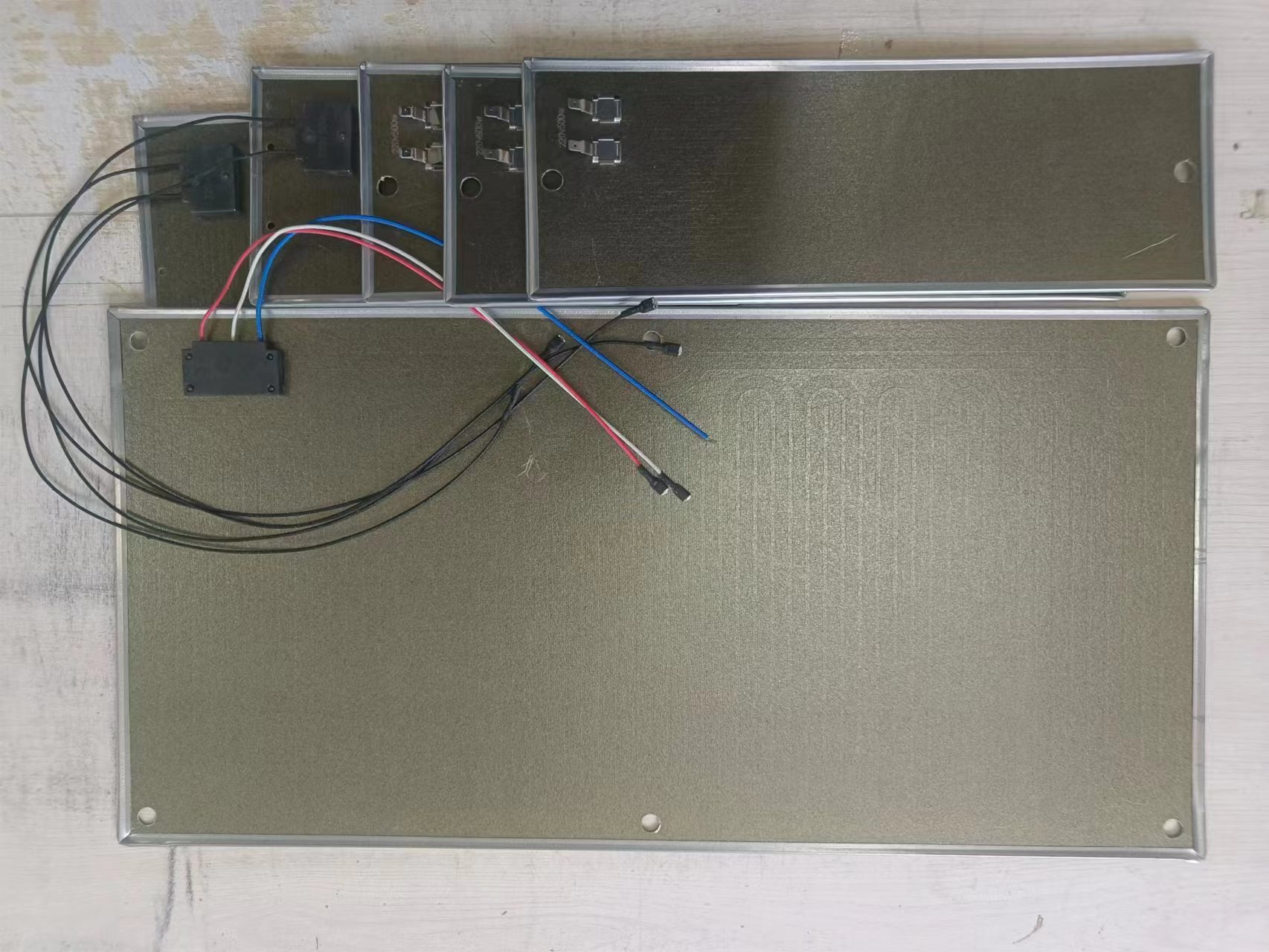

Recommended Products