Synthetic mica tape

Product Category:

Mica Tape

Keywords:

Yuefeng Mica

- Description

-

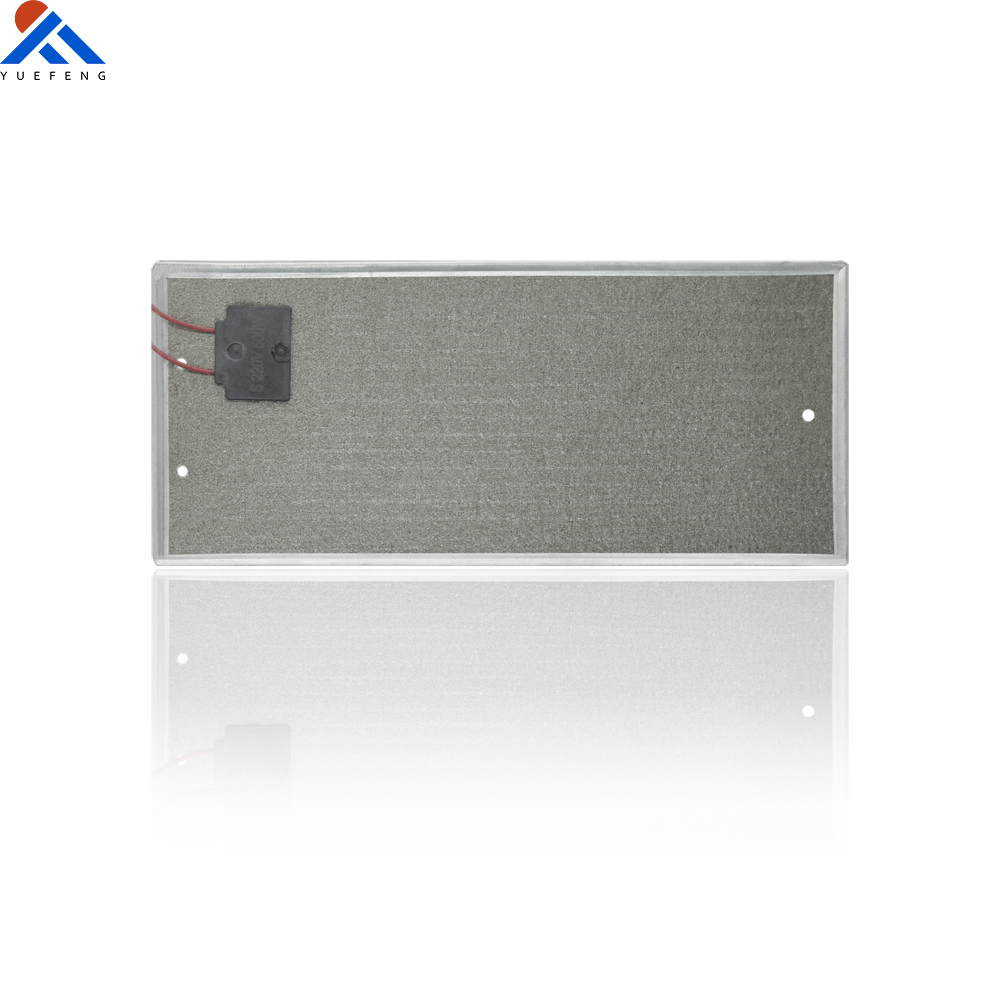

- Commodity name: Synthetic mica tape

Product Overview

Synthetic mica tape stands out as a cutting-edge insulating material, engineered to tackle the most demanding industrial applications. Crafted from superior-quality synthetic mica, this tape mimics the natural mineral’s structure but offers enhanced purity, performance consistency, and environmental benefits. Designed for both thermal and electrical insulation, synthetic mica tape boasts excellent resistance to high temperatures, exceptional dielectric strength, and an unmatched flame-retardant capability.

Whether used in fire-resistant cables, high-voltage equipment, or other crucial systems, synthetic mica tape delivers precision, reliability, and safety.

Key Features

High Thermal Resistance

Operates effectively at temperatures exceeding 1000°C, maintaining structural integrity under extreme conditions.

Outstanding Electrical Insulation

Provides high dielectric strength to prevent current leakage and ensure consistent performance.

Non-Combustible and Flame-Resistant

Ideal for fire safety systems, synthetic mica tape offers reliable protection against fire hazards, adhering to strict safety regulations.

Enhanced Durability

Resistant to mechanical wear and chemical exposure, ensuring long-lasting insulation in harsh environments.

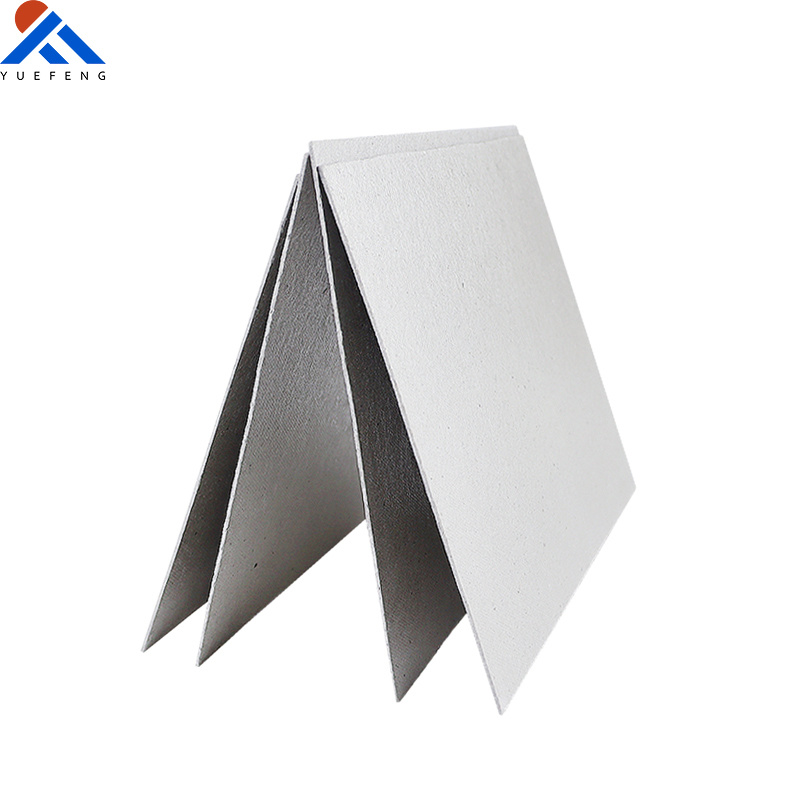

Flexible Construction

Easily wraps around irregular components, providing seamless coverage for intricate or complex structures.

Key Applications

Synthetic mica tape is a versatile solution across numerous industries, including but not limited to:

Fire-Resistant Cables

Ensures operational continuity in critical applications, such as emergency lighting, alarm systems, and transportation networks.

Generators and Transformers

Enhances reliability by insulating and protecting high-voltage systems from electrical faults.

Aerospace and Automotive

Provides durable fireproof insulation for advanced engines and other high-performance systems.

Industrial Ovens and Furnaces

Safeguards equipment in high-temperature environments, extending their operational lifespan.

Chemical and Petrochemical Plants

Resists chemical degradation while maintaining insulation in challenging industrial environments.

Benefits at a Glance

Superior safety with enhanced flame resistance.

High performance under extreme temperatures and voltages.

Long-term cost-effectiveness thanks to outstanding durability.

Customizable in thicknesses and sizes to meet application-specific requirements.

Certified to meet rigorous industrial and environmental standards.

Call to Action

Recommended Products