Fabricated Mica Parts

Product Category:

Fabricated Mica Parts

Keywords:

Yuefeng Mica

- Description

-

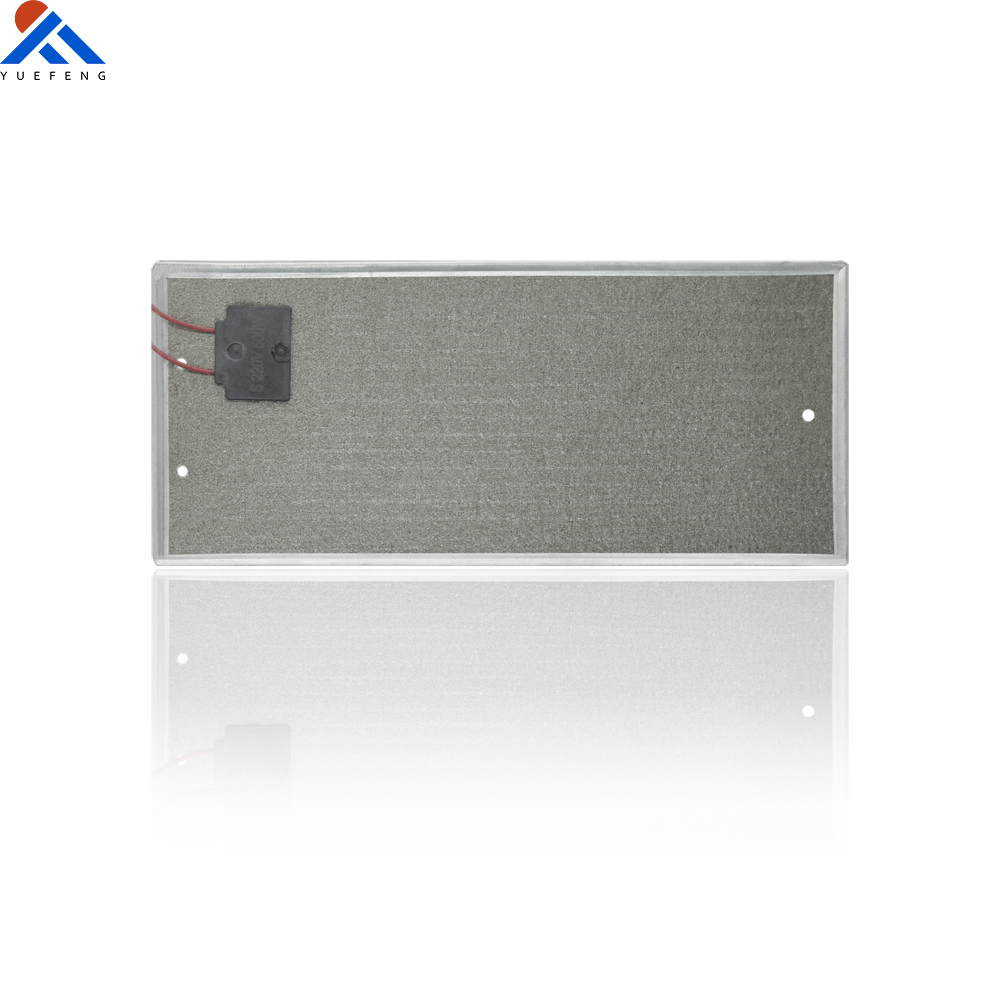

- Commodity name: Fabricated Mica Parts

Precision Cutting CNC Machining Custom ShapesCUSTOM COMPONENTS

Precision Cutting CNC Machining Custom ShapesCUSTOM COMPONENTSFabricated Mica Parts & Precision Machined Components

High-performance custom mica components designed for extreme environments. We offer precise CNC machining, laser cutting, and stamping services to meet your exact specifications.

Fabrication Capabilities:

- ● Laser & Water Jet Cutting

- ● Stamping & Punching

- ● CNC Milling & Drilling

- ● +/- 0.05mm Tolerance

Why Choose Fabricated Mica?

🌡️ Extreme Thermal Stability

Withstands temperatures up to 1000°C (Phlogopite) without losing structural integrity or shape.

⚡ High Dielectric Strength

Excellent electrical insulation properties prevent current leakage and short circuits in high-voltage equipment.

📐 Precision Dimensionality

Retains precise shape and size even under severe temperature fluctuations and mechanical stress.

🛡️ Chemical Inertness

Resistant to oils, solvents, and acids, ensuring longevity in corrosive industrial environments.

Material Specifications

Property Muscovite (Standard) Phlogopite (High Temp) Max Operating Temp 500°C - 600°C 800°C - 1000°C Density (g/cm³) 2.6 - 3.2 2.6 - 3.2 Breakdown Voltage 120 - 200 kV/mm High (Varies by grade) Hardness (Mohs) 2.8 - 3.2 2.3 - 3.0 Key Applications

- Electrical: Insulators for commutators, transformers, and capacitors.

- Aerospace: Thermal shielding and high-temp gaskets.

- Industrial: Wear-resistant linings for chemical equipment.

Our Manufacturing Process

1. Material Selection: Choosing best-fit Muscovite or Phlogopite sheets.

2. Precision Prototyping: CAD design verification.

3. Advanced Cutting: Laser / Water Jet / CNC Machining.

4. Surface Treatment: Polishing and coating per request.

5. Quality Control: 100% dimensional inspection.

Frequently Asked Questions

Technical guide to machining, properties, and applications of custom mica parts.

How do you machine mica parts without delamination? +

To prevent delamination, the mica sheet must be securely clamped during machining. We use sharp, carbide-tipped tools operating at high speeds with low feed rates. Sandwiching the mica between sacrificial boards (like plywood) during drilling or cutting also effectively stops edge flaking.Can mica sheets be laser cut? +

Yes, especially for thin sheets (under 2mm). Laser cutting seals the edges as it cuts, reducing the risk of fraying. However, for thicker rigid sheets, CNC machining or water jet cutting is often preferred to avoid charring the edges.What is the tolerance level for fabricated mica parts? +

For CNC machined parts, we typically achieve tolerances of +/- 0.05mm to +/- 0.1mm. Stamped parts usually have a tolerance of +/- 0.1mm to 0.2mm depending on the thickness and complexity of the die.What tools are best for cutting mica? +

Due to the abrasive nature of mica minerals, Tungsten Carbide or Diamond-tipped tools are essential for longevity and clean cuts. High-Speed Steel (HSS) tools dull very quickly and cause rough edges.Is mica dust hazardous during the fabrication process? +

Finished mica parts are safe, but machining generates fine dust. While mica itself is non-toxic, inhaling high concentrations of dust can irritate the lungs. We use strict dust extraction systems, and operators wear protective masks (PPE) during fabrication.What are the common applications for fabricated mica parts? +

They are widely used as insulating washers in semiconductors, waveguide covers in microwaves, commutator segments in motors, thermal barriers in aerospace black boxes, and observation windows in high-temp furnaces.How do you bond mica parts to metal components? +

We use high-temperature adhesives such as silicone-based glues (for up to 250°C) or ceramic/silicate-based cements (for up to 1000°C), depending on the application's operating temperature.What is the difference between stamped and machined mica parts? +

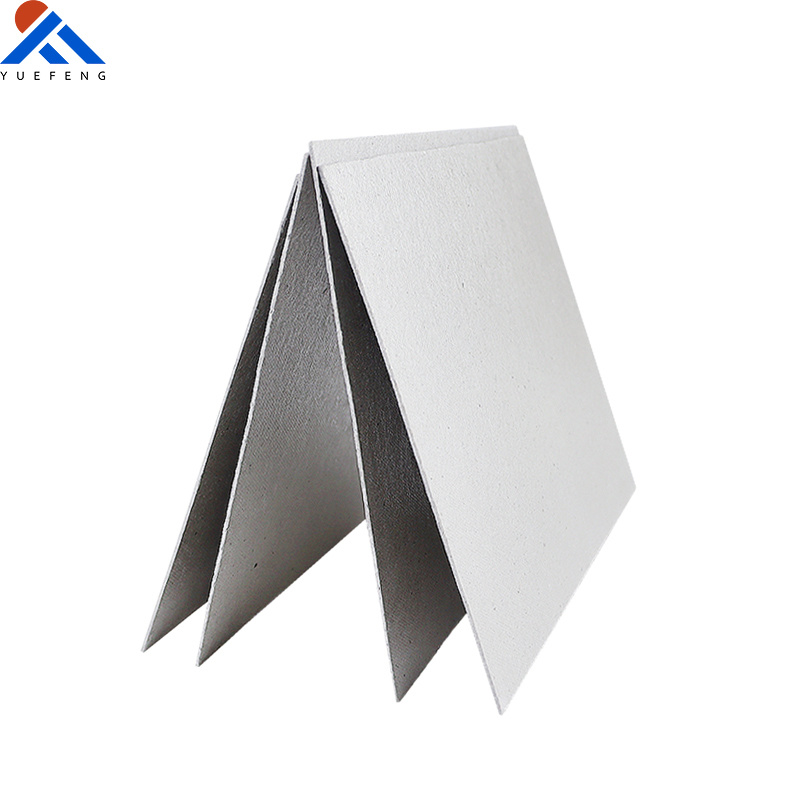

Stamped Parts: Best for high-volume production of thin parts (< 2mm). Requires a custom die but lower unit cost.

Machined Parts: Best for thicker parts, low volume, or complex 3D shapes. Uses CNC mills/lathes with no tooling cost but higher unit time.Can mica parts withstand high voltage arcing? +

Yes, mica has excellent arc resistance and high dielectric strength (>20 kV/mm). It does not carbonize easily, making it an ideal material for arc chutes and high-voltage switchgear insulation.Why is mica used for microwave waveguide covers? +

Mica is transparent to microwaves (low dielectric loss), meaning it allows energy to pass through without heating up. Simultaneously, it withstands high temperatures and blocks food/steam from entering the waveguide.What is the maximum thickness for stamped mica parts? +

Typically, we recommend stamping for mica sheets up to 2.0mm thick. Beyond this thickness, the material tends to delaminate or crack under the impact of the punch. Thicker parts should be CNC machined or water-jet cut.How do you design a mica gasket for high-temperature sealing? +

Designing a mica gasket requires accounting for its lack of compressibility compared to rubber. It is often used in combination with a metallic layer (spiral wound) or graphite. The surface finish of the mating flanges must be smooth to ensure a tight seal.Is fabricated mica brittle? +

Yes, rigid mica parts are relatively brittle compared to plastics or metals. They have high compressive strength but low tensile strength. Designs should avoid sharp internal corners (use fillets) and excessive bending stress.Difference in machinability between Muscovite and Phlogopite? +

Muscovite is harder and allows for cleaner, sharper edges during machining. Phlogopite is softer and slightly more prone to flaking or creating dust, requiring more careful tool speed adjustments for precision parts.How to prevent edge flaking when drilling mica? +

We use a "sandwich" technique: the mica part is clamped tightly between two sacrificial boards (like wood or acrylic). The drill bit passes through the top board, the mica, and the bottom board, preventing the mica layers from lifting on entry or exit.Can fabricated mica parts be used in vacuum environments? +

Yes, high-grade mica with low-outgassing binders (or pure natural mica) is suitable for vacuum applications. It is stable and does not release significant volatiles that would contaminate the vacuum chamber.What surface finishes are available for custom mica parts? +

Standard finish is natural matte. We can also provide sanded (thickness calibration), polished, or silicone-coated finishes depending on the requirement for smoothness or moisture resistance.What cutting technologies do you use to ensure the precision of mica parts? +

We utilize a combination of CNC machining and advanced laser cutting technologies for intricate designs. By adhering to equipment standards comparable to a professional Fiber Laser Cutting Machine manufacturer, we ensure that every fabricated mica part meets tight tolerances with smooth, clean edges.

Recommended Products