Rigid Mica Sheet

Product Category:

Mica Sheet

Keywords:

Yuefeng Mica

- Description

-

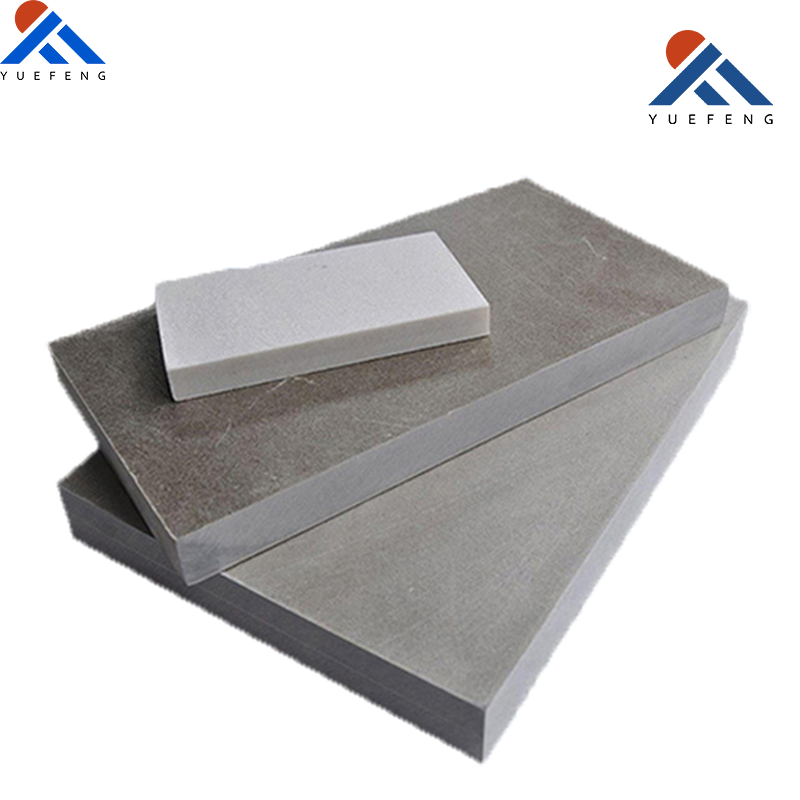

- Commodity name: Rigid Mica Sheet

Thickness: 0.1-100mmUL 94 V-0IEC 60371INDUSTRIAL INSULATIONRigid Mica Sheet (Muscovite & Phlogopite)

High-performance rigid laminate plates designed for high-voltage and high-temperature insulation up to 1000°C. Ideal for furnace linings, heating elements, and gaskets.

SELECT MATERIAL TYPE:

Phlogopite (1000°C) Muscovite (500°C)POPULAR THICKNESS:

0.5mm 1.0mm 5.0mm 20mmTechnical Specifications

Property HP-5 (Muscovite) HP-5P (Phlogopite) Binder Content approx. 10% (Silicone) approx. 10% (Silicone) Density (IEC 371-2) 2.15 - 2.30 g/cm³ 2.15 - 2.30 g/cm³ Heat Resistance (Cont.) 500°C (932°F) 750°C - 1000°C Dielectric Strength (20°C) > 20 kV/mm > 18 kV/mm Water Absorption < 1.0% < 1.0% Standard Sheet Size 1000mm x 600mm / 1000mm x 1200mm / 1000mm x 2400mm 🔥 Extreme Thermal Stability

Designed to maintain structural integrity under continuous high heat. Phlogopite sheets are perfect for open-flame applications up to 1000°C.

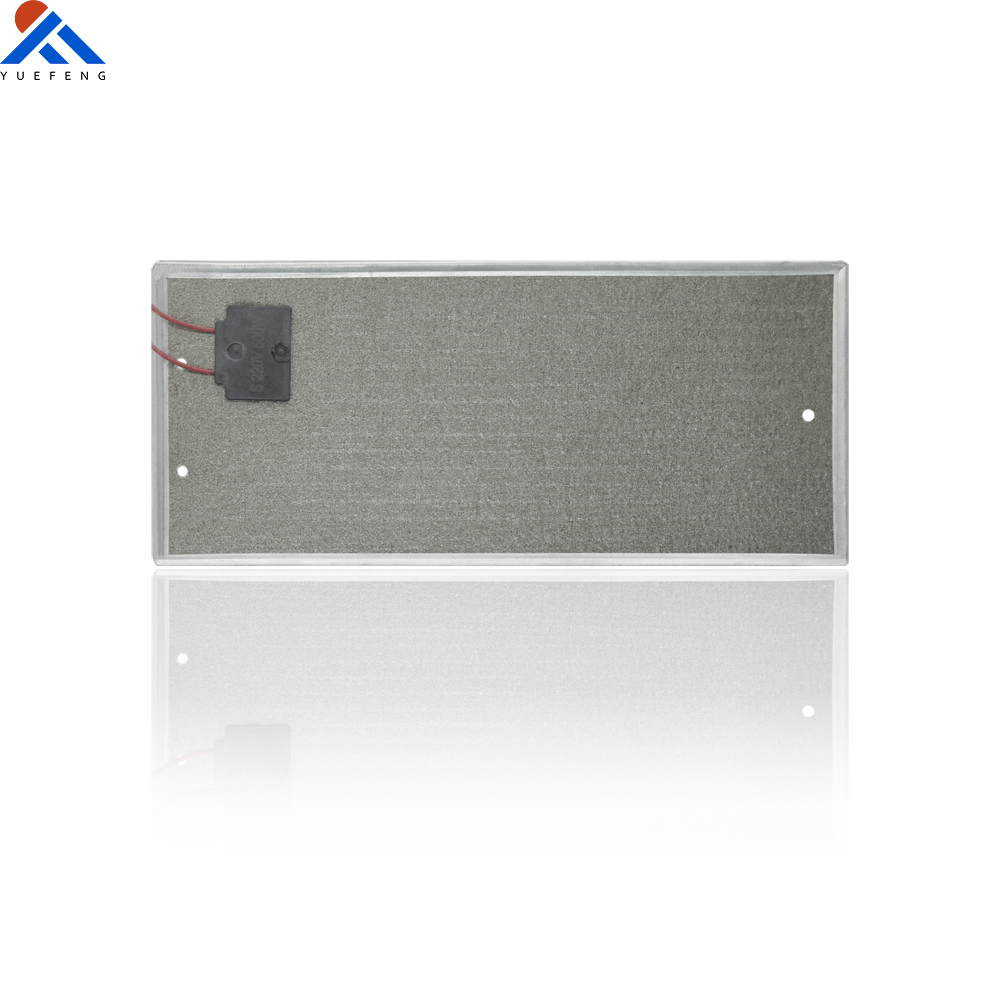

⚡ High Dielectric Strength

Excellent electrical insulation properties make it an ideal choice for switchgear, arc chutes, and transformer spacers.

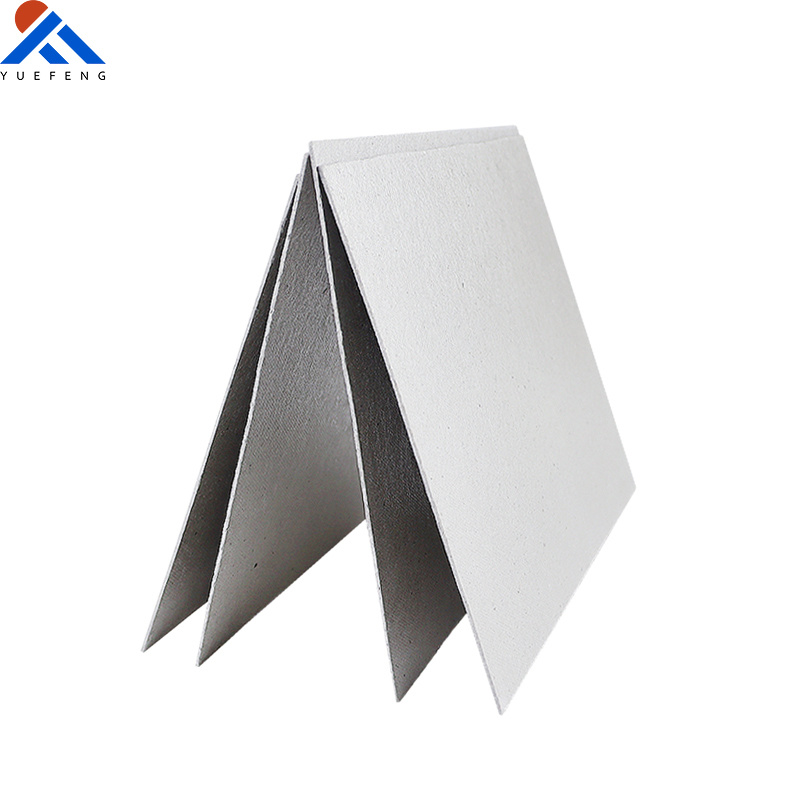

🛠️ Excellent Machinability

Rigid mica sheets can be easily cut, drilled, punched, or stamped into complex gaskets and parts without delamination.

Frequently Asked Questions

Comprehensive guide to Rigid Mica Sheet properties and usage.

What is the difference between rigid and flexible mica sheets? +

Rigid mica sheets contain less binder and are heat-pressed to form a hard, board-like material for structural support. Flexible mica sheets use a different binder system or curing process to remain pliable, allowing them to wrap around coils or curved surfaces.How do you cut rigid mica sheets? +

Thin sheets (<2mm) can be stamped or cut with heavy shears. Thicker sheets (up to 100mm) require CNC milling, band saws, or water jet cutting. We recommend using carbide-tipped tools to prevent edge wear and delamination.What is rigid mica sheet used for? +

It is used for high-temperature electrical and thermal insulation. Common applications include furnace linings, heating element supports, induction furnace insulation, high-voltage switchgear barriers, and microwave waveguide covers.Can rigid mica sheets be machined? +

Yes, they have excellent machinability. They can be sawed, drilled, milled, and turned into complex shapes and gaskets. However, dust extraction is recommended during machining.What is the maximum temperature for rigid mica sheets? +

Muscovite rigid sheets can withstand continuous temperatures up to 500°C (932°F). Phlogopite rigid sheets are designed for extreme heat and can withstand up to 1000°C (1832°F).How is rigid mica sheet manufactured? +

High-quality mica paper is impregnated with heat-resistant silicone resin. Multiple layers are stacked to the desired thickness and then subjected to high pressure and heat in a press to cure the resin, forming a dense, rigid board.Is rigid mica sheet waterproof? +

Rigid mica sheets have very low water absorption (<1%) and are moisture-resistant due to the silicone resin binder. However, they are not typically designed for long-term submersion in water.Does rigid mica sheet contain asbestos? +

No. All our mica products are 100% asbestos-free and non-toxic. They are safe, eco-friendly alternatives to asbestos insulation.What is the dielectric strength of rigid mica sheet? +

Rigid mica sheets have excellent electrical insulation properties, typically exceeding 20 kV/mm. This makes them suitable for high-voltage applications.Can I drill holes in rigid mica sheet? +

Yes. To prevent edge chipping or delamination, it is recommended to clamp the mica sheet between two sacrificial boards (like wood or acrylic) and drill through the stack using high-speed steel or carbide bits.Is rigid mica sheet suitable for furnace insulation? +

Yes, Phlogopite rigid mica sheets are specifically designed for furnace insulation. They can withstand temperatures up to 1000°C and are resistant to open flames and thermal shock.What thickness does rigid mica sheet come in? +

We offer a wide range of thicknesses, typically from 0.1mm up to 100mm. Standard sheets are available in 1000x600mm or 1000x1200mm sizes, but can be custom cut.Can rigid mica sheet be used in a microwave? +

Yes, it is commonly used as a waveguide cover. Rigid mica is transparent to microwave energy but blocks steam and food particles from entering the electronic components.What is the density of rigid mica sheet? +

The density typically ranges from 2.15 g/cm³ to 2.45 g/cm³, depending on the specific mica content and resin type used in manufacturing.Is rigid mica sheet chemically resistant? +

Yes, it has excellent resistance to oils, solvents, acids, and alkalis. This chemical inertness ensures longevity even in harsh industrial environments.How to glue rigid mica sheets together? +

For high-temperature applications, use silicone-based adhesives (up to 250°C) or inorganic silicate/ceramic adhesives (up to 1000°C) to bond sheets together or to other substrates.What are the mechanical properties of rigid mica sheet? +

Rigid mica has high compressive strength (excellent for washers and supports) and good flexural strength (>150 MPa). However, it is relatively brittle compared to metals, so it should not be subjected to extreme impact or bending stress.

Recommended Products