Mica tube

Product Category:

Mica Tube

Keywords:

Yuefeng Mica

- Description

-

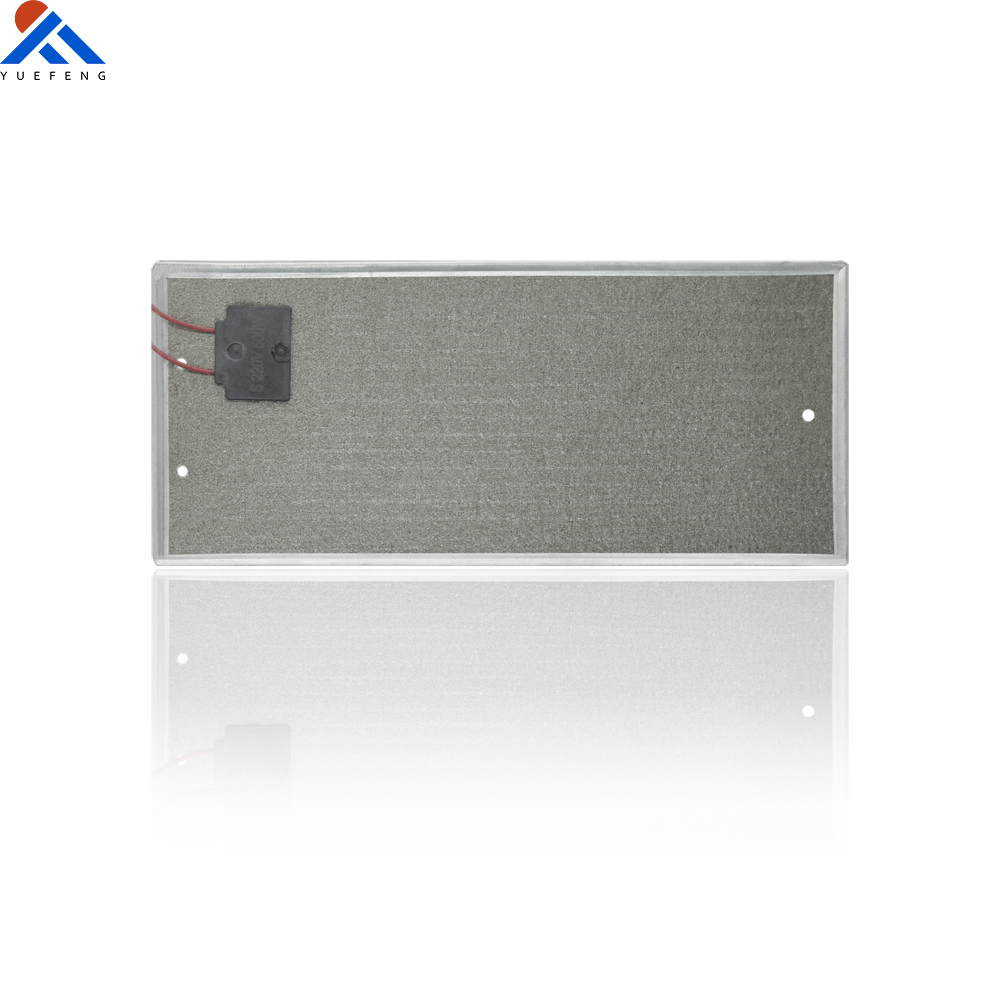

- Commodity name: Mica tube

INSULATION TUBING

INSULATION TUBINGHigh-Temp Mica Insulation Tube (Rigid & Flexible)

Engineered from premium mica paper and silicone resin. Provides exceptional dielectric strength (>20kV/mm) and thermal resistance up to 1000°C. Ideal for motors, furnaces, and heating elements.

- ✓ Heat Resistance: Up to 1000°C (Peak)

- ✓ Diameter Range: 5mm - 150mm (Customizable)

- ✓ Eco-Friendly: 100% Asbestos-Free

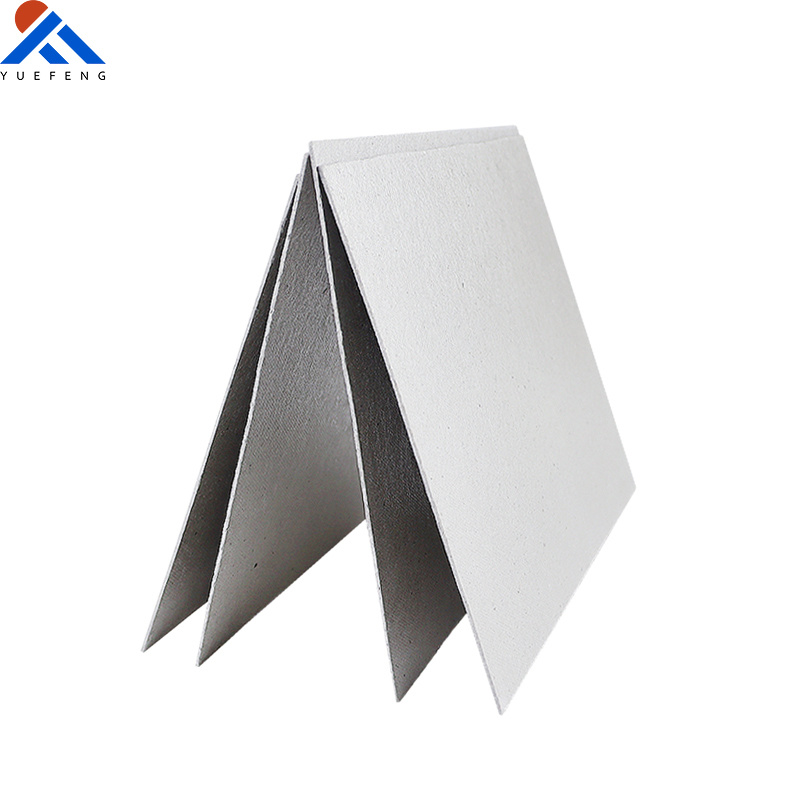

Product Overview

Our Mica Tubes are rigid or flexible insulating materials manufactured from high-quality mica paper bonded with high-temperature resistant silicone or epoxy resin. Formed through precise molding or rolling processes, they offer superior structural integrity.

Compared to traditional ceramic or fiberglass tubes, mica tubes combine better machinability with superior heat endurance, making them an ideal choice for high-demand industrial environments such as electric arc furnaces and high-voltage switchgear.

🔥 Extreme Heat Resistance

Continuous working temperature of 500°C with short-term resistance up to 1000°C.

⚡ Superior Insulation

Dielectric strength >20 kV/mm ensuring stable performance under high voltage.

⚙️ Mechanically Stable

Resistant to cracking, deformation, and high pressure loads. Easily machinable.

Technical Specifications

Parameter Value / Range Material Composition Muscovite / Phlogopite Mica + Silicone Resin Working Temperature 500°C (Continuous) / 1000°C (Peak) Dielectric Strength > 20 kV/mm Density 2.2 – 2.4 g/cm³ Diameter Range 5 mm – 150 mm (Customizable) Flame Resistance UL 94 V-0 Compliant Frequently Asked Questions about Mica Tubes

Comprehensive guide to mica tube properties, usage, and selection.

What is a mica tube used for? +

Mica tubes are primarily used for electrical and thermal insulation in high-temperature environments. Common applications include insulating sleeves for heating elements (in toasters, hair dryers), coil formers in motors and generators, and protective barriers in metallurgical furnaces and high-voltage switchgear.How are mica tubes manufactured? +

They are made by bonding high-quality mica paper (Muscovite or Phlogopite) with heat-resistant silicone or epoxy resin. The material is wound or rolled onto a mandrel under high pressure and heat to form a dense, rigid tube, which is then cured to ensure structural stability.Difference between Muscovite and Phlogopite mica tubes? +

Muscovite (White/Grey): Offers superior mechanical strength and electrical properties but is limited to 500°C continuous use.

Phlogopite (Green/Gold): Slightly softer but offers higher thermal resistance, capable of withstanding up to 700°C - 1000°C, making it better for extreme heat applications.What is the maximum operating temperature of a mica tube? +

Muscovite mica tubes can operate continuously at 500°C (932°F). Phlogopite mica tubes can withstand continuous temperatures of 700°C (1292°F) and short-term peaks up to 1000°C (1832°F).Is mica tube waterproof? +

Mica itself has very low water absorption. The silicone resin binder adds moisture resistance, making the tubes suitable for humid environments. However, they are not typically designed to be fully submerged in water for long periods.What does dielectric strength mean for a mica tube? +

Dielectric strength measures the tube's ability to resist electrical breakdown under high voltage. Our mica tubes typically have a dielectric strength greater than 20 kV/mm, meaning a 1mm thick wall can withstand 20,000 volts without conducting.Can mica tubes be machined or customized? +

Yes. Unlike ceramic tubes, rigid mica tubes have excellent machinability. They can be sawed, drilled, milled, or turned to precise tolerances without cracking. We also offer customization for inner/outer diameters and lengths.Why is silicone resin used as a binder? +

Silicone resin is used because it has exceptional thermal stability and flexibility. It does not degrade or carbonize at high temperatures (unlike standard organic glues), ensuring the mica tube maintains its structural integrity up to 500-1000°C.Are mica tubes mechanically strong? +

Yes, rigid mica tubes have good compressive strength and are resistant to mechanical shock. While not as load-bearing as steel, they are significantly tougher and less brittle than ceramic or glass tubes.Do mica tubes absorb moisture? +

They have very low moisture absorption rates (<1%). However, for applications in high-humidity environments, specific resin treatments can be applied to further enhance water resistance.Can I use a mica tube as a simple bushing or spacer? +

Absolutely. Due to their rigidity and thermal stability, mica tubes are excellent choices for electrically insulating bushings, spacers, and standoffs in industrial machinery.How do I choose the right type of mica tube? +

Consider the operating temperature first. If it's below 500°C, Muscovite is suitable and cost-effective. For >500°C, choose Phlogopite. Also consider if you need rigid (structural) or flexible (wrapping) characteristics.What are the signs that a mica tube needs replacement? +

Signs include visible delamination (layers peeling apart), surface carbonization (blackening due to arcing), or physical cracks. If the dielectric strength drops, it should be replaced immediately to prevent safety hazards.How should mica tubes be handled and stored? +

Store in a dry, cool place away from direct moisture. Handle with care to avoid dropping or crushing, as strong impacts can cause delamination of the mica layers.What are the advantages of mica tubes over ceramic tubes? +

Mica tubes are less brittle, can be machined into complex shapes, and can be produced with thinner walls than ceramics while maintaining comparable thermal resistance. They are also generally more cost-effective for custom sizes.Can mica tubes be used in high-voltage switchgear? +

Yes, their high dielectric strength and resistance to electrical arcing make them ideal for insulating phases, arc chutes, and other components in high-voltage switchgear systems.Are mica tubes suitable for aerospace applications? +

Yes. Due to their lightweight nature, flame retardancy (UL 94 V-0), and ability to withstand extreme thermal cycling, they are used in aerospace for battery insulation, wire protection, and thermal barriers.

Recommended Products