Mica Tapes | Heat Resistant Fireproof Electrical Insulation

Product Category:

Mica Tape

Keywords:

Yuefeng Mica

- Description

-

- Commodity name: Mica Tapes | Heat Resistant Fireproof Electrical Insulation

📖 Table of Contents

- What are Mica Tapes?

- Types of Mica Tapes

- Key Features & Benefits

- Manufacturing Process & Quality Control

- Technical Specifications

- Performance Comparison

- Applications & Use Cases

- Design & Selection Guide

- Installation & Handling

- Packaging & Delivery

- Certifications & Compliance

- FAQ

- Inquiry / Contact Us

What are Mica Tapes?

Mica tapes are flexible, fire-resistant insulating materials composed of engineered mica paper backed with reinforcing substrates and bonded with high-temperature resin systems. Unlike conventional electrical tapes that soften, melt, or carbonize at elevated temperatures, mica tapes retain structural integrity and insulation properties even in direct flame exposure. This capability enables cables and components to survive fire long enough to maintain critical circuits—supporting safe evacuation, emergency communications, and essential controls.

At the heart of mica tapes lies the unique phyllosilicate structure of mica minerals. Their sheet-like crystals provide natural dielectric strength, outstanding thermal stability, and chemical inertness. When processed into uniform mica paper and laminated with glass cloth or polymer films, these layers create a composite that is both resilient and easy to process—ideal for precision slitting into narrow rolls that wrap neatly around conductors and windings.

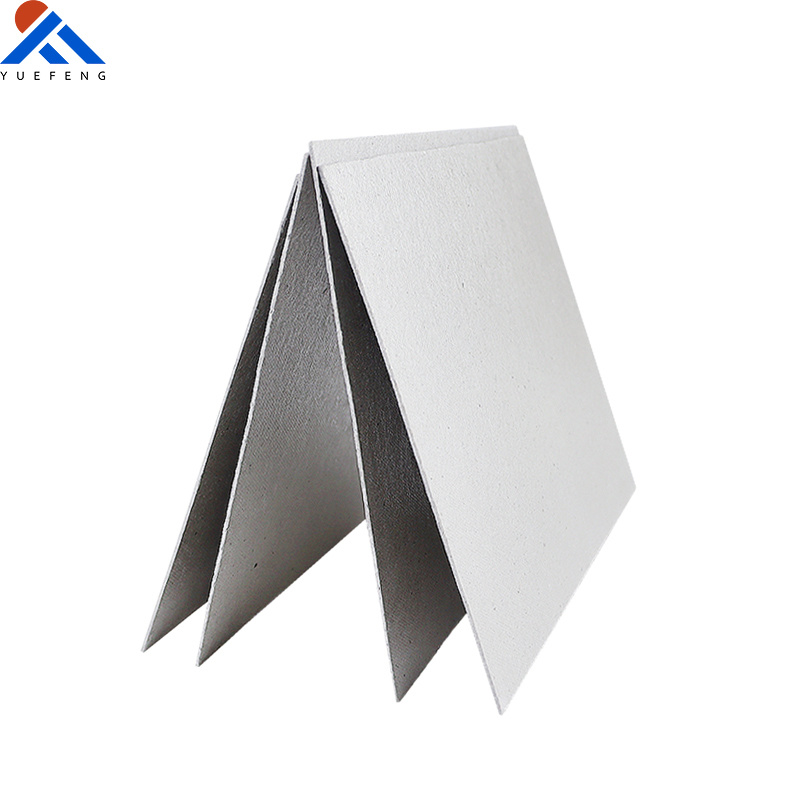

Typical constructions may include one or multiple mica layers, reinforced by glass cloth for tensile strength or polyester film for handling and dimensional stability. The result is a tape that can be applied with consistent tension, overlaps predictably, and forms a reliable insulation barrier after installation and curing (if applicable).

Types of Mica Tapes

Mica tapes are categorized by the mica mineral, the reinforcement, and the target application. Selecting the right combination ensures the best balance of fire endurance, dielectric performance, mechanical flexibility, and process efficiency.

Phlogopite Mica Tape

Phlogopite exhibits superior high-temperature behavior and thermal shock resistance. Tapes based on phlogopite are widely used in fire-resistant (fire survival) cables required by safety regulations in tunnels, subways, high-rise buildings, hospitals, and airports. They maintain insulation during flame exposure and resist cracking during rapid heating and cooling cycles.

- Best for: fire survival cables, furnace-adjacent wiring, high-heat environments.

- Strengths: excellent flame resistance, robust under thermal cycling, good mechanical flexibility.

- Trade-offs: slightly lower dielectric strength than muscovite; typically brownish color.

Muscovite Mica Tape

Muscovite provides higher inherent dielectric strength and good mechanical properties at moderate temperatures. In motors and transformers where long-term electrical performance is critical, muscovite-based tapes are preferred for interturn, interlayer, and phase insulation.

- Best for: motors, generators, transformers (slot liners, turn insulation, layer barriers).

- Strengths: high dielectric strength, dimensional stability, cleaner edge finish in slitting.

- Trade-offs: not as thermally extreme as phlogopite under flame shock.

Glass-Mica Tape

By laminating mica paper to glass cloth, the tape gains tensile strength and tear resistance, allowing tight winding around small diameters without tearing. This construction is common where mechanical robustness during processing is essential.

- Best for: high-speed cable wrapping machines, tight-bend applications.

- Strengths: improved handling, stable overlaps, consistent thickness during wrapping.

Polyester/PET-Mica Tape

When mica is reinforced with polyester (PET) film, the tape benefits from improved dimensional stability and ease of handling. PET-mica tapes are often selected for cost-effective electrical insulation where exposure to open flame is not continuous but thermal margin is still needed.

- Best for: appliance wiring, auxiliary insulation, moderate heat environments.

- Strengths: good tensile stability, economical, easy processing.

Adhesive Systems & Specials

Depending on the process, tapes may be supplied with dry-bond resin systems that activate at elevated temperature, or with pressure-sensitive adhesive (PSA) for positioning. Specialty versions include low-smoke/halogen-free constructions, double-side mica for symmetrical builds, and ultra-thin tapes for compact windings.

Key Features & Benefits

Fire Resistance

Mica tapes are engineered to maintain electrical insulation under direct flame for extended periods—commonly 90–180 minutes, depending on construction and thickness. In cable applications, this helps circuits remain operational during evacuation and emergency response, complying with fire survival standards such as IEC 60331 (circuit integrity under fire).

Thermal Endurance

Continuous operation up to 500°C and short-term peaks to 1000°C are achievable in well-designed systems. The low thermal conductivity of mica reduces heat transfer between layers, protecting sensitive components and preventing premature insulation breakdown.

Electrical Insulation

Dielectric strength typically exceeds 20 kV/mm, with high insulation resistance and low dielectric loss. This ensures stable performance under elevated voltage stress, even in humid conditions—an advantage over many polymer-only tapes that absorb moisture or soften with heat.

Mechanical Flexibility & Processability

Despite their ceramic-like thermal properties, mica tapes remain flexible and can be wound around tight radii without cracking. Reinforcements (glass cloth, PET) increase tensile strength and help achieve uniform wraps with predictable overlap ratios on high-speed equipment.

Chemical & Environmental Stability

Mica is inherently inert to oils, greases, and many solvents, and shows low moisture uptake. Formulations are asbestos-free and designed to meet RoHS and REACH requirements, supporting global market access and environmentally responsible design.

Customizable Formats

Available in a wide range of widths (5–1000 mm) and thicknesses (0.1–1.0 mm). Constructions can be tailored (muscovite vs. phlogopite, glass vs. PET backing, single vs. multiple mica layers) to optimize for a specific application, line speed, and regulatory target.

Manufacturing Process & Quality Control

The production of mica tapes begins with mineral selection. Raw mica is evaluated for purity, flake size, moisture, and mineral composition. It is then converted to mica paper via splitting or pulping processes that produce uniform fibers. The paper is impregnated with a high-temperature silicone or epoxy resin to achieve the desired dielectric and mechanical properties.

Next, mica paper is laminated to a reinforcing substrate such as glass cloth or PET film. Controlled lamination pressure and temperature ensure intimate bonding and consistent thickness across the web. After curing and conditioning, the laminate is slit into tapes with tight width tolerance and clean edges to prevent fiber loose ends that could lead to partial discharge.

Quality control includes: thickness measurement, tensile/elongation tests, dielectric strength verification, fire endurance trials (e.g., IEC 60331), and visual inspection for defects. Batch traceability is maintained, and certificates can be issued upon request (RoHS/REACH, asbestos-free declarations, and test reports).

Technical Specifications

Parameter Typical Value / Range Notes Material System Muscovite or Phlogopite mica paper + glass cloth / PET Resin-bonded laminates Working Temperature Up to 500°C continuous Application-dependent Peak Temperature Up to 1000°C short-term Depends on exposure duration Fire Resistance 90–180 minutes Refer to IEC 60331 Dielectric Strength >20 kV/mm Measured on standard thickness Thickness 0.10 – 1.00 mm Other thicknesses on request Width 5 – 1000 mm Custom slitting available Moisture Absorption <0.5% Low uptake Chemical Resistance Good – Excellent Oils, greases, many solvents Compliance RoHS, REACH, asbestos-free Documentation available Values are typical and not guaranteed. Final performance depends on tape construction, wrapping tension, overlap ratio, curing conditions (if applicable), and the operating environment.

Performance Comparison

The table below compares mica tapes with fiberglass and ceramic tapes in key attributes important to electrical safety and reliability.

Property Mica Tape Fiberglass Tape Ceramic Tape Fire Resistance Excellent (90–180 min) Poor Good Max Temperature Up to 1000°C ~500°C ~800°C Dielectric Strength High Low–Medium Medium Flexibility High Medium Low (brittle) Chemical Resistance Good – Excellent Good Moderate Processability Good (consistent wrapping) Good Poor (fragile) In practice, fiberglass tapes may be adequate for moderate-temperature insulation but lack the circuit integrity under fire that mica tapes provide. Ceramic tapes tolerate heat but can be brittle and challenging to process at high speeds. Mica strikes a balance: fire survival + dielectric strength + flexibility.

Applications & Use Cases

Fire-Resistant (Fire Survival) Cables

Mica tapes are the backbone of fire survival cable constructions used in tunnels, subways, high-rise buildings, data centers, chemical plants, and public venues. When wrapped around conductors and insulated cores, the tapes help the cable continue carrying current during direct flame exposure—maintaining power to critical systems like emergency lighting, smoke extraction, alarms, and communication networks.

Regulatory frameworks often specify performance time (e.g., 90 or 180 minutes) and electrical integrity criteria under flame, shock, and water spray. By choosing the appropriate phlogopite-based tape and ensuring proper overlap and wrapping tension, cable makers can meet stringent standards while optimizing manufacturing throughput.

Motors & Generators

Within rotating machinery, mica tapes serve as turn insulation, interlayer barriers, and slot liners. Their dielectric strength prevents partial discharge, while their thermal stability withstands hot spots near windings and iron cores. Muscovite-based tapes are favored where voltage stress dominates; phlogopite may be used in zones that experience greater heat.

Transformers & High-Voltage Equipment

Transformers rely on stable insulation to prevent arcing between windings and structural components. Mica tapes provide robust barriers in layer-to-layer builds, tap-changer sections, and lead exits. Low moisture uptake and chemical inertness support long service life in humid or polluted environments.

Household & Commercial Appliances

Appliances such as ovens, heaters, hair dryers, and coffee makers benefit from mica’s fire resistance and insulation capacity. Tapes insulate heating elements, protect metallic housings, and add thermal margin to wiring harnesses—helping products meet safety standards without compromising form factor.

Railway, Marine & Aerospace

In transportation, flame spread and smoke generation are tightly regulated. Mica tapes contribute to cable systems that maintain function during fire events, improving survivability for signaling, communications, and emergency circuits. Their reliability in vibration-prone environments also makes them suitable for aerospace auxiliary systems.

Design & Selection Guide

- Define Objectives: Is the priority fire survival time, dielectric performance, or mechanical handling? This guides the choice between phlogopite vs. muscovite and glass vs. PET backing.

- Set Wrapping Parameters: Establish overlap ratio (e.g., 50–66%), tension, and line speed. Uniform overlap ensures consistent insulation thickness and prevents pinholes.

- Choose Thickness & Width: Balance the required insulation margin with processing efficiency. Thicker tapes increase dielectric spacing but may reduce flexibility on small diameters.

- Assess Environment: Consider exposure to oils, solvents, humidity, and thermal cycles. Select resins and backings that maintain properties in those conditions.

- Compliance: For cables, confirm applicable IEC 60331 or regional fire survival standards. For motors/transformers, verify insulation class and voltage requirements.

- Prototyping: Run pilot wraps to validate machine settings, cure schedules (if used), and final electrical tests before full-scale production.

Installation & Handling

- Storage: Keep tapes in dry, shaded conditions; avoid temperature extremes. Re-seal opened rolls to limit moisture uptake.

- Preparation: Ensure clean conductors and remove burrs that could snag or cut the tape. Calibrate wrapping tension for the chosen backing.

- Application: Maintain steady overlap and avoid wrinkles. For multi-layer builds, stagger joints and verify layer count.

- Quality Checks: Inspect for edge fraying, pinholes, and uniformity. Perform dielectric and insulation resistance tests on representative samples.

- Safety: Although asbestos-free, handle in ventilated areas if dust is generated. Follow PPE guidelines in line with factory policies.

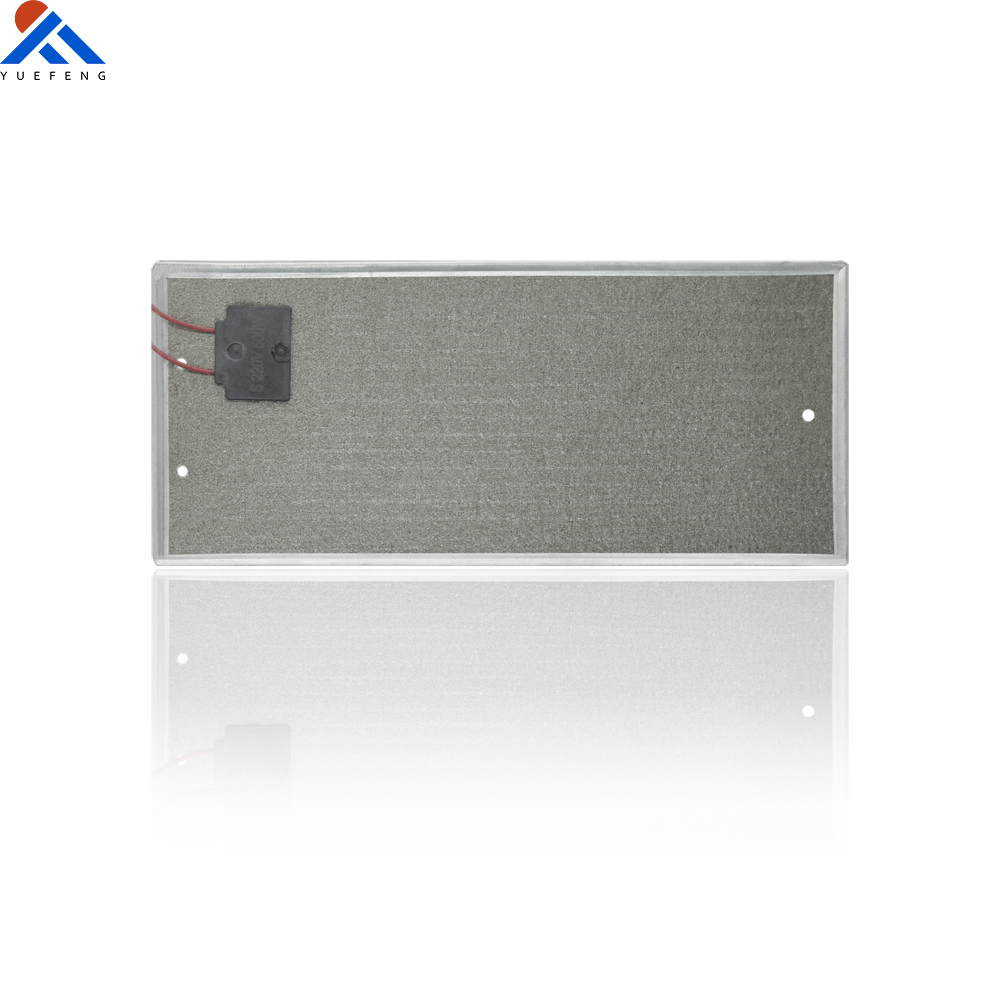

Packaging & Delivery

Mica tapes are supplied in sealed rolls to minimize moisture ingress. Standard packaging includes individual bags with desiccant, carton boxing, and palletization for bulk shipments. Lead times are typically 7–15 business days for stocked constructions; custom builds may require additional time for lamination and QA approvals. Global delivery is available by courier, air freight, or sea, with commercial documentation (invoices, packing lists, certificates) prepared upon request.

Certifications & Compliance

- IEC 60331 (circuit integrity under fire) for cable applications.

- ISO 9001:2015 quality management across production and QA.

- RoHS & REACH compliance; asbestos-free declarations available.

- Additional tests (thermal aging, moisture conditioning, chemical resistance) on request.

FAQ

1) How long can mica tapes withstand fire?

Depending on tape construction (mica content, backing type, thickness) and the cable design (overlap ratio, number of wraps), mica tapes can maintain electrical integrity under flame for 90–180 minutes. Compliance is verified with standards such as IEC 60331.

2) Which type should I choose: phlogopite or muscovite?

Choose phlogopite for maximum fire endurance and thermal shock tolerance (typical for fire survival cables). Select muscovite when high dielectric strength is paramount (motors, transformers). Hybrid solutions are possible where zones face different stresses.

3) Can I customize width and thickness?

Yes. Standard widths span 5–1000 mm with typical thicknesses of 0.1–1.0 mm. We offer custom slitting for tight tolerance needs and narrow-slot winding.

4) Are mica tapes asbestos-free and eco-compliant?

All mica tapes are 100% asbestos-free and designed to meet RoHS and REACH requirements. Low-smoke and halogen-free constructions are available for regulated sectors.

5) What’s the typical lead time and MOQ?

Standard items ship in 7–15 business days. MOQs are flexible for prototyping; production volumes benefit from planning forecasts to optimize lamination schedules and logistics.

6) How do I ensure consistent quality on my winding line?

Run a short DOE (design of experiments) on tension, overlap, and line speed; inspect edges for fray; and validate dielectric performance post-wrap. We can provide guidance and sample rolls for trials.

Inquiry / Contact Us

Ready to specify mica tapes for cable, motor, or transformer applications? Our engineering team can help select the optimal construction, define wrapping parameters, and provide datasheets and samples for validation.

Recommended Products