Ceramic fiber mica roll

Product Category:

Mica Roll

Keywords:

Yuefeng Mica

- Description

-

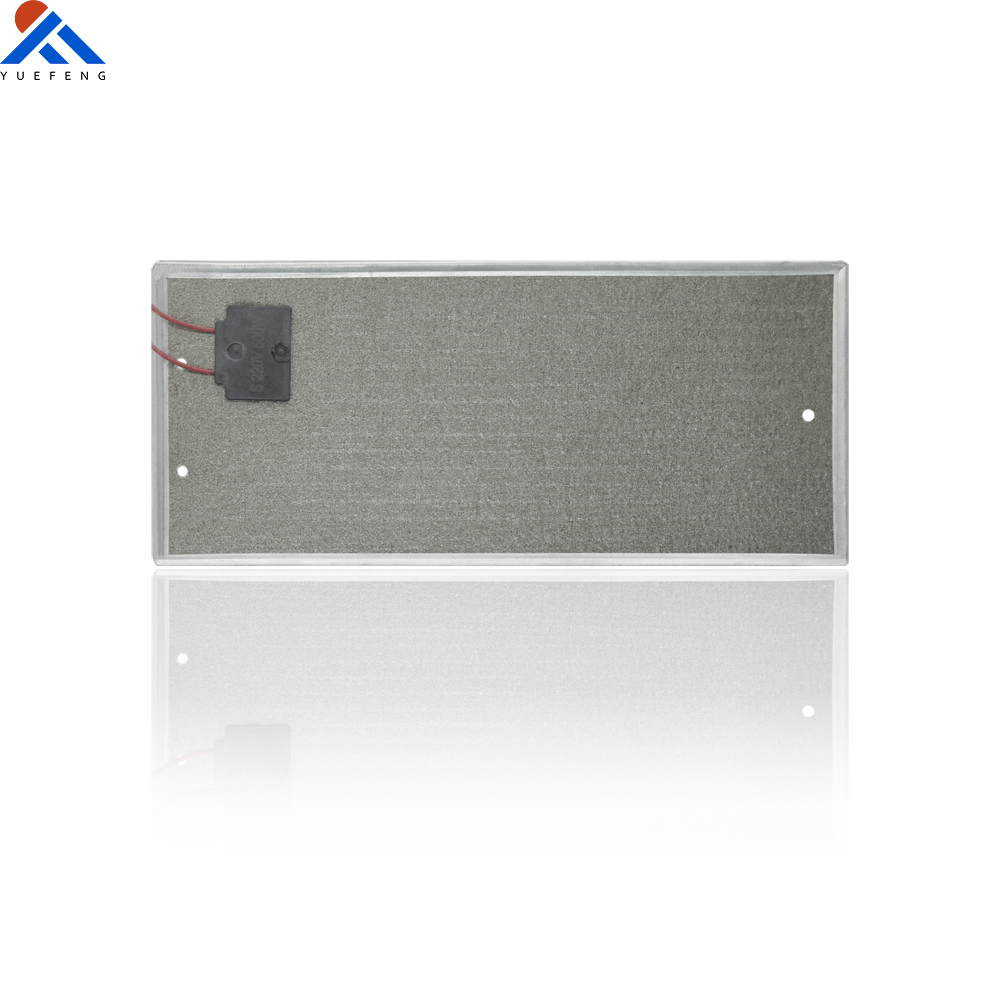

- Commodity name: Ceramic fiber mica roll

Ceramic fiber mica rolls are high-performance thermal insulation materials made from ceramic fibers and high-quality mica flakes through a special process. They combine the high-temperature resistance and low thermal conductivity of ceramic fibers with the excellent insulation and pressure resistance of mica, forming a composite roll material with multiple functions such as heat insulation, insulation, and chemical corrosion resistance. They are widely used in various high-temperature industrial scenarios.

Core Features

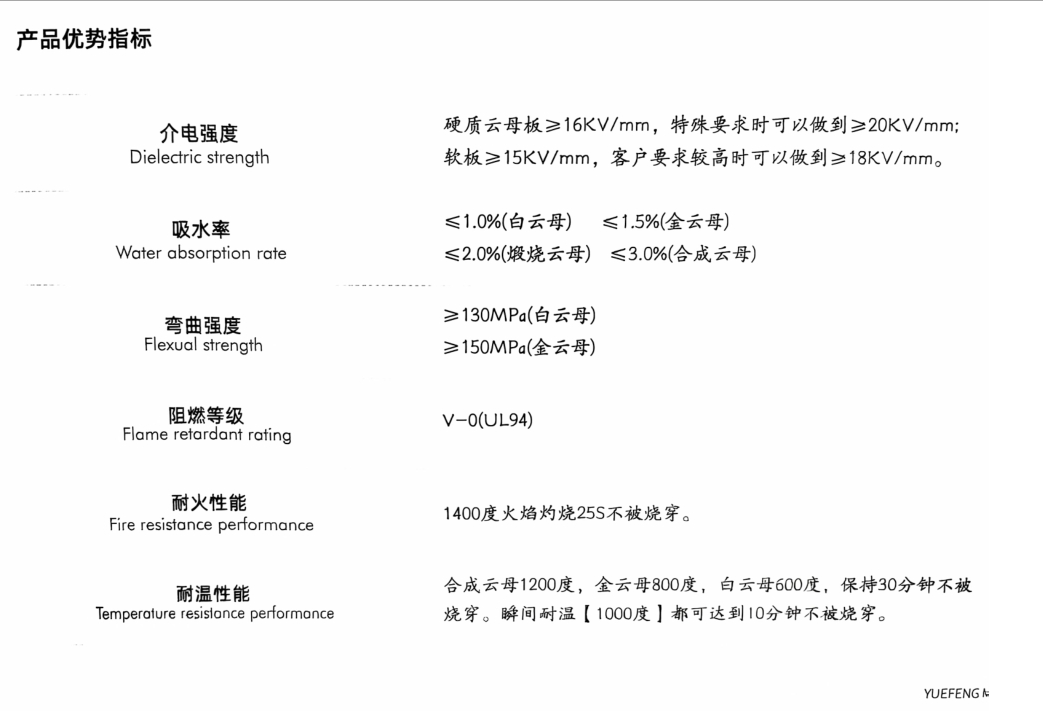

Excellent High-Temperature Resistance: Able to withstand high-temperature environments of 600-1000℃ for extended periods (specific temperature resistance varies by model) and can withstand short-term high temperatures up to 1200℃. Maintains structural stability under open flames or high-temperature radiation without melting or shedding.

Excellent Electrical Insulation: Breakdown voltage up to 20-50kV/mm, insulation resistance ≥10¹⁴Ω・cm, meeting the insulation protection needs of high-voltage electrical equipment and effectively reducing the risk of leakage current.

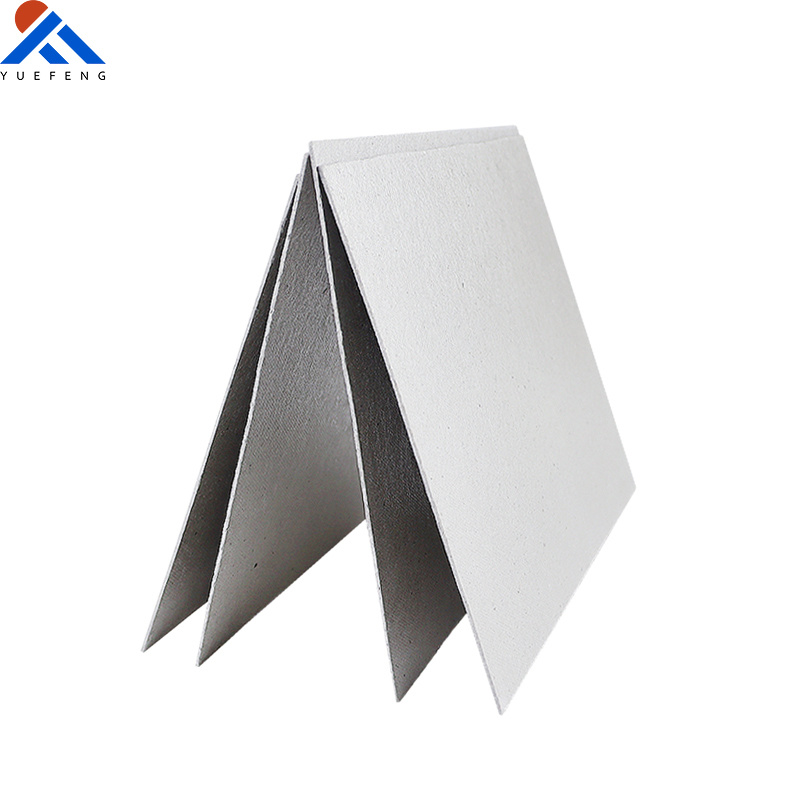

Good Flexibility and Processability: The rolls are flexible and can be cut, bent, and wrapped according to actual needs. They are easy to apply to irregularly shaped equipment surfaces (such as pipes, kiln walls, motor coils, etc.), resulting in high installation efficiency.

Low Thermal Conductivity and Energy Saving: Thermal conductivity ≤0.12W/(m・K) (at 25℃), significantly reducing heat transfer, reducing equipment energy consumption, and improving the thermal efficiency of high-temperature systems.

Weather Resistance and Corrosion Resistance: Exhibits good resistance to most acids, alkalis, oils, and organic solvents and is not easily affected by moisture or aging. Its service life is more than 30% longer than traditional insulation materials.

Applicable Scenarios

Industrial Kiln Field: Used for kiln linings, furnace door seals, and flue insulation to reduce heat loss and protect the furnace structure.

Electrical Equipment Field: Used as insulation gaskets or coil winding materials for equipment such as motors, transformers, and reactors to improve the equipment's temperature resistance and operational safety.

High-Temperature Piping Field: Wrapped around the outer layer of steam pipes and high-temperature air ducts to provide heat insulation and anti-scalding protection.

Metallurgical Machinery Field: Used as a heat insulation layer for steelmaking and casting equipment, as well as a surface protective layer for high-temperature molds.

Why Choose Ceramic Fiber Mica Rolls?

Recommended Products