Mica Heating Film

Discover reliable and efficient mica heating film engineered for uniform heat distribution. Perfect for industrial, medical, and home applications demanding consistent high performance.

Product Category:

Mica heating film

Keywords:

Yuefeng Mica

- Description

-

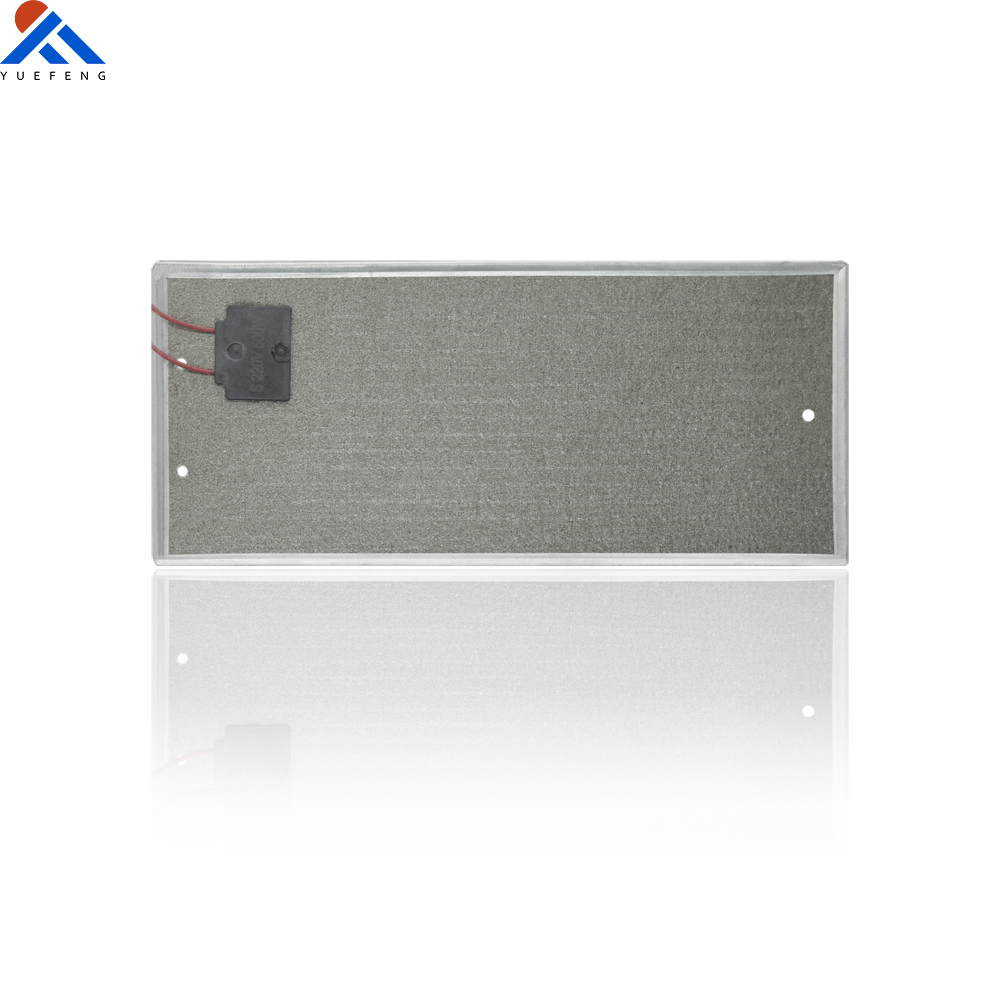

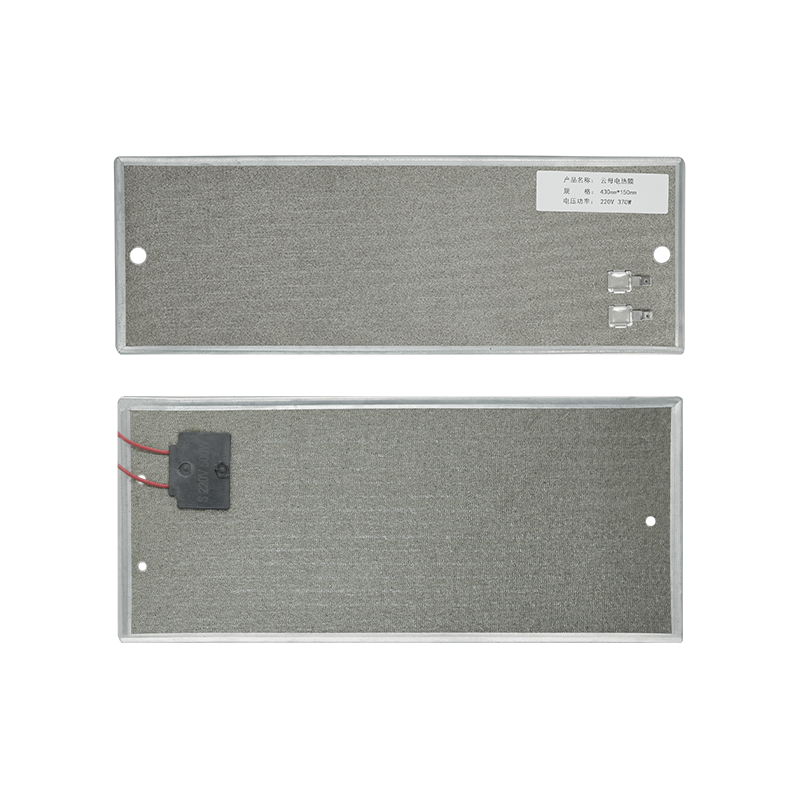

- Commodity name: Mica Heating Film

3-Sec Rapid Heat Ultra-Thin RoHS CompliantHEATING ELEMENTS

3-Sec Rapid Heat Ultra-Thin RoHS CompliantHEATING ELEMENTSMica Heating Film & Etched Foil Elements

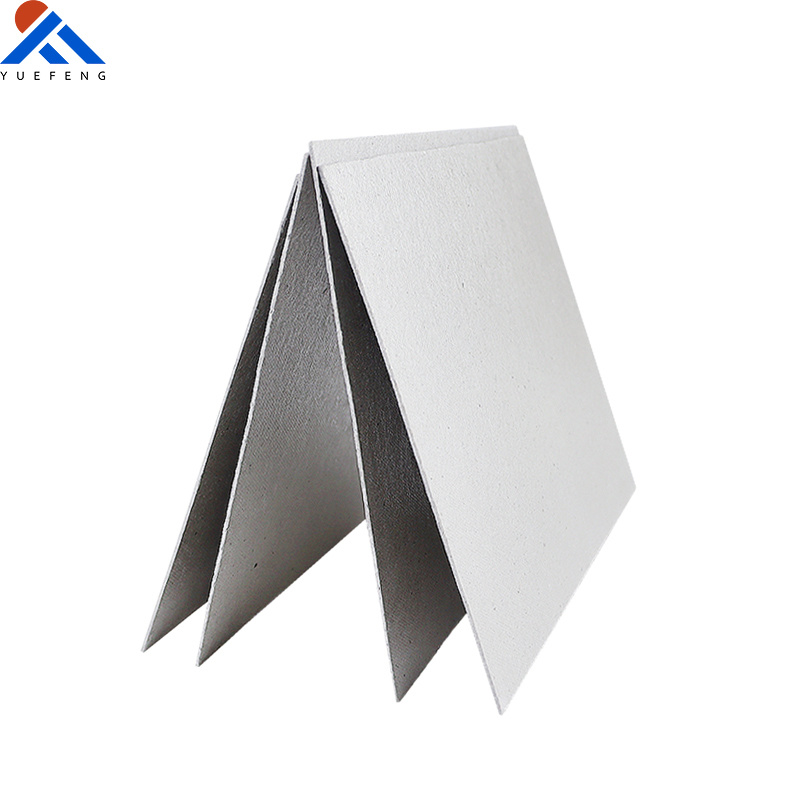

High-performance etched foil heating elements sandwiched between mica sheets. Delivers rapid, uniform heat distribution with exceptional thermal stability up to 500°C.

- ⚡Rapid Response: Heats up in < 3 seconds.

- 🔋Stable Power: No attenuation over 30,000+ hours.

- 🛠️Customizable: Voltage (5V-380V), Wattage, Shape & Holes.

Technical Specifications

Parameter Standard Value / Range Surface Temperature 50°C ~ 330°C (Custom up to 500°C) Input Voltage AC/DC 5V ~ 380V Power Density ≤ 0.85 W/cm² Dielectric Strength 1800V / 1min (No Breakdown) Insulation Resistance ≥ 100 MΩ Heating Element Type Etched Foil (Nickel-Chrome Alloy) Service Life > 30,000 Hours (Semi-permanent) Target Applications

🏠 Home Appliances

Toasters, Radiant Heaters, Electric Irons, Rice Cookers, Hair Dryers.

🏭 Industrial Equipment

Plastic Molding Machinery, Laminators, Sealing Machines, 3D Printers.

🚗 Automotive & EV

Battery Heating Systems, Seat Heaters, Mirror Defrosters.

Frequently Asked Questions

What is mica heating film?

Mica heating film is a flat, thin heating element consisting of an etched metal foil (usually nickel-chrome) sandwiched between two layers of mica insulation. It provides efficient, uniform heat transfer.What is the difference between etched foil and wire wound mica heaters?

Etched foil heaters cover a larger surface area with a flat element, providing more uniform heat distribution and faster response times than round wire wound elements, which can create hot spots.What is the maximum temperature for mica heating film?

Standard mica heating films operate efficiently up to 300-350°C. However, with high-temperature phlogopite mica and special alloys, they can withstand up to 500-600°C.Can I customize the shape and voltage?

Yes, absolutely. Since we use etching technology, we can design custom circuit patterns for any voltage (12V, 24V, 110V, 220V) and cut the mica into any shape with holes or cutouts.Does mica heating film require a heat sink?

It depends on the power density. For high wattage densities (>0.5 W/cm²), clamping the heater to a heat sink (metal plate) is recommended to prevent overheating and ensure efficient heat transfer.Is mica heating film waterproof?

No, standard mica heaters are not waterproof as mica layers are mechanically bonded. For moisture-prone environments, we recommend enclosing the heater in a metal sheath or using silicone rubber heaters instead.How fast does it heat up?

Mica heating films have very low thermal mass, allowing them to heat up extremely fast—typically reaching operating temperature within 3 to 10 seconds.Can you integrate a thermostat or sensor?

Yes, we can integrate bimetallic thermostats, thermal fuses, or NTC thermistors directly onto the mica heater assembly for temperature control and overheat protection.What is the typical thickness of the film?

The typical thickness ranges from 0.5mm to 1.0mm, depending on the thickness of the mica sheets used for insulation (usually 0.2mm - 0.5mm per layer).Is it safe? Does it emit smoke?

High-quality mica heaters are smokeless and odorless after the initial first-use "burn-in". Mica is naturally fire-retardant (UL 94 V-0) and does not emit toxic fumes.How do I mount the heater?

Mica heaters are typically mounted by clamping them between a metal heat sink and a backing plate. We can also provide holes for screws or spring-loaded clamps. Adhesive backing is not recommended for high temperatures.Can it work with DC power?

Yes, resistive heating elements work equally well with AC or DC power. We can design low-voltage DC heaters (e.g., 12V, 24V) for automotive or portable applications.What is the lifespan of mica heating film?

Under proper usage conditions (not exceeding max temperature), the lifespan typically exceeds 30,000 hours, making it a semi-permanent heating solution.What certifications do your heaters have?

Our materials comply with RoHS and REACH standards. The finished heating elements are designed to meet UL and CE safety requirements for electrical appliances.Can I use it for space heating (convection)?

Yes, "Micathermic" heaters are a popular application. Large mica heating panels are used to heat air via convection and radiation, providing efficient and silent room heating.

Recommended Products