Mica Washers

Product Category:

Mica Gasket Flange

Keywords:

Yuefeng Mica

- Description

-

- Commodity name: Mica Washers

📖 Table of Contents

- What are Mica Washers?

- Why Mica: Material Science in Brief

- Key Features & Benefits

- Manufacturing Process & Quality Control

- Technical Specifications

- Performance Comparison

- Applications & Use Cases

- Design & Selection Guide

- Installation & Handling

- Packaging & Delivery

- Certifications & Compliance

- FAQ

- Inquiry / Contact Us

What are Mica Washers?

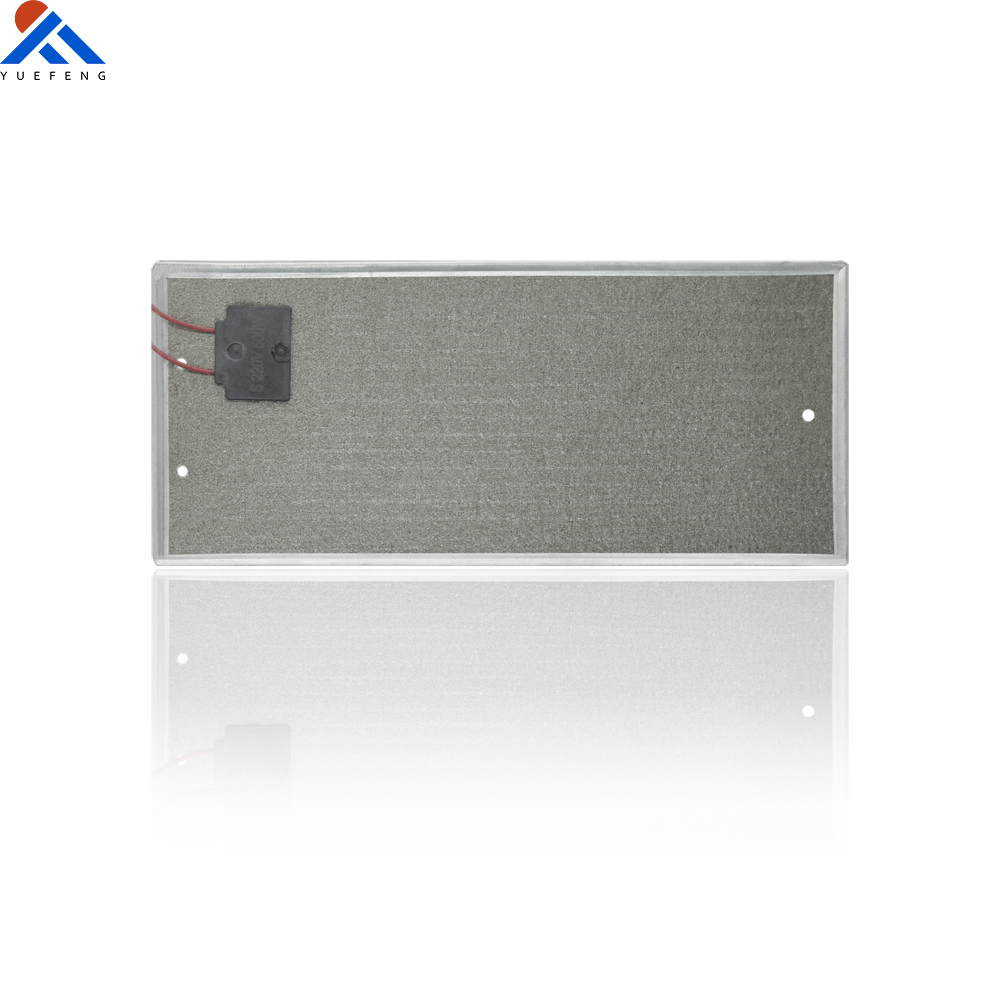

Mica washers are precision-cut insulating gaskets manufactured from layered mica paper (muscovite or phlogopite) bonded with high-temperature resins. They provide a rare combination of thermal endurance, dielectric strength, and dimensional stability that conventional rubber, plastic, or even ceramics struggle to match across all three dimensions.

In demanding systems, heat and voltage often coexist: a fastening point near a heating element, a coil termination inside a motor, or a standoff in a transformer. A single failure at these interfaces can lead to thermal runaway, short circuits, or costly downtime. Mica washers mitigate these risks by maintaining insulation integrity at 500°C continuous and tolerating up to 1000°C short-term, while resisting mechanical compression and vibration.

Typical washer geometries include circular, slotted, oval, multi-hole, and keyed shapes. Dimensions are customized to match bolt sizes and contact areas, ensuring uniform pressure distribution, tight tolerance fit, and consistent electrical isolation.

Why Mica: Material Science in Brief

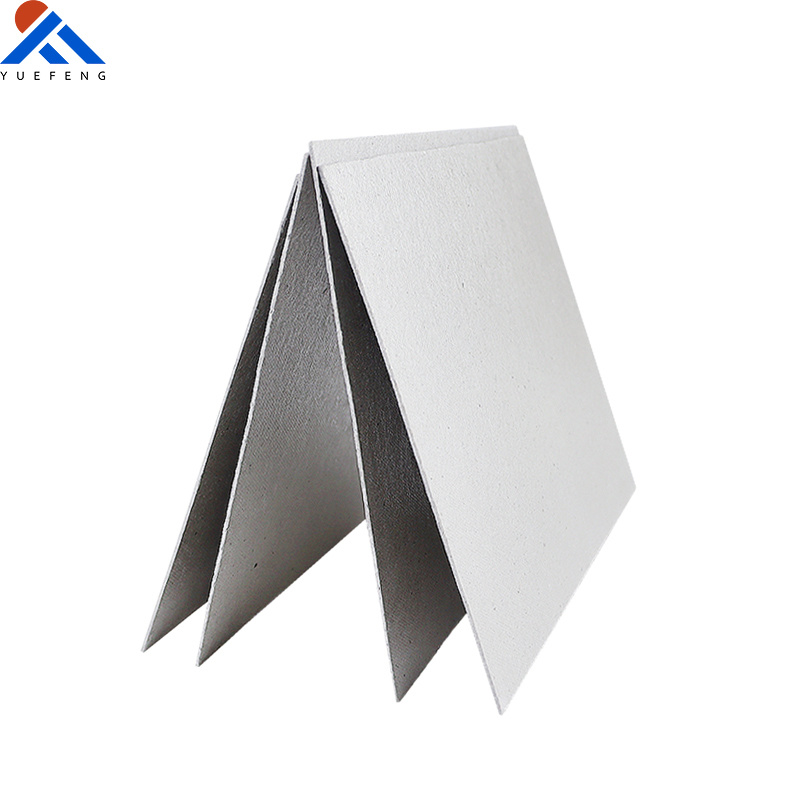

Mica is a group of silicate minerals with a sheet-like (phyllosilicate) crystal structure. This layered structure yields natural cleavage into thin, flexible sheets that are inherently electrically insulating, chemically stable, and thermally robust. Two types dominate industrial insulation:

- Muscovite: Excellent dielectric performance and mechanical strength, preferred for high-voltage insulation where stability is crucial.

- Phlogopite: Superior high-temperature endurance and thermal shock resistance, suitable for applications near heating elements and furnaces.

When processed into mica paper and laminated with silicone/epoxy resins, these minerals form engineered sheets with predictable thickness, improved machinability, and enhanced flexural strength—perfect for mass production of washers with tight tolerances.

Key Features & Benefits

1) Thermal Endurance

- Continuous service temperature: 500°C.

- Short-term peaks: up to 1000°C (application-dependent).

- Low thermal degradation and excellent flame resistance (UL 94 V-0 equivalent systems available).

2) Electrical Insulation

- Dielectric strength typically >20 kV/mm.

- High insulation resistance with minimal leakage even at elevated humidity.

- Reduced risk of partial discharge and arcing at interfaces.

3) Mechanical Stability

- High compressive strength; resists creep under bolt preload.

- Non-brittle compared with ceramics; better vibration tolerance.

- Dimensional stability across thermal cycles; maintains gasket integrity.

4) Chemical & Environmental

- Resistant to oils, greases, many solvents, and weak acids/alkalis.

- Low moisture absorption (<0.3%) supports stable dielectric behavior.

- Asbestos-free, low smoke, RoHS/REACH friendly.

5) Customization

- Inner diameter: 2–100 mm; Outer diameter: 5–150 mm; Thickness: 0.1–5 mm (other sizes by request).

- Flat, countersunk, slotted, keyed, and multi-hole geometries per drawing.

- Material selection: muscovite, phlogopite, or hybrid laminate by application.

Manufacturing Process & Quality Control

Production begins with raw mica mineral selection and incoming inspection (purity, flake size, moisture). Mica is processed into paper or thin sheets, then impregnated with a controlled resin system. Lamination, hot pressing, and curing consolidate the structure and set final mechanical properties. After conditioning, sheets are slit and die-cut or CNC milled into washers to drawing specifications.

Quality control includes thickness tolerance checks, visual/optical inspection for defects, dielectric strength testing, and dimensional verification (ID/OD/flatness). For critical industries (HV equipment, aerospace), traceability and batch-level certificates are issued. On request, samples undergo thermal aging, salt-fog, and chemical resistance testing to validate lifecycle performance.

Technical Specifications

Parameter Value / Range Notes Material Muscovite / Phlogopite + resin Select by temperature and dielectric priority Working Temperature 500°C continuous Short-term peaks up to 1000°C Dielectric Strength >20 kV/mm Depends on thickness and preparation Density 2.2 – 2.4 g/cm³ Typical laminated sheet values Thickness Range 0.1 – 5.0 mm Tighter tolerances available Outer Diameter 5 – 150 mm Larger OD by stitched/segment methods Inner Diameter 2 – 100 mm Match common fastener sizes Thermal Conductivity 0.3 – 0.5 W/m·K Low; supports heat isolation Moisture Absorption <0.3% Promotes insulation stability Flame Resistance UL 94 V-0 (systems) Asbestos-free laminates Chemical Resistance Good – Excellent Oils, greases, many solvents Color Natural brown/gray Varies with mica type Values are typical and not guaranteed; final performance depends on geometry, assembly preload, environment, and operating profile. Please request a datasheet for certified values.

Performance Comparison

Mica washers outperform plastics/PTFE in heat and flame resistance while avoiding the brittleness of ceramics. This balance of properties reduces risk at mechanical–electrical interfaces. Below is a high-level comparison.

Property Mica Washer Ceramic Washer Plastic/PTFE Washer Max Temp Resistance Up to 1000°C ~800°C ~200°C Dielectric Strength High Medium Medium Mechanical Robustness High (non-brittle) Brittle Moderate Flame Resistance Excellent Good Poor Chemical Resistance Excellent Moderate Low–Moderate Machinability Good Poor Excellent Cost-Effectiveness High Medium High In practice, engineers choose mica washers when thermal margin and electrical safety are non-negotiable. For example, around cartridge heaters, band heaters, or transformer terminals, mica offers a stable insulation barrier without the cracking risk of ceramics.

Applications & Use Cases

1) Electric Motors & Generators

Mica washers isolate fastening points, coil terminals, and bus connections from grounded frames. They also distribute preload forces uniformly, protecting enamel insulation on windings. In traction motors and industrial drives, their resistance to vibration and thermal cycling extends service intervals.

2) Household & Commercial Appliances

Common in ovens, irons, toasters, coffee makers, and hair dryers, mica washers separate heating elements from metallic housings, preventing nuisance trips, leakage currents, and burn hazards. Their low smoke behavior and asbestos-free formulation support consumer safety requirements.

3) Transformers & High-Voltage Equipment

Power transformers, capacitors, and switchgear require controlled clearances and reliable insulation at mounting points. Mica washers help prevent arcing at bolt interfaces and maintain dielectric spacing under mechanical stress. Their low moisture uptake maintains insulation resistance in humid sites.

4) Industrial Heating & Metallurgy

In arc furnaces, kilns, and metallurgical equipment, mica withstands radiant heat and thermal shock around refractory interfaces, heater stands, and coil fixtures. Compared with ceramics, mica tolerates handling shock during maintenance—reducing breakage and downtime.

5) Automotive & New Energy

From exhaust systems and engine bay sensors to battery module fixtures in EVs, mica washers provide heat shielding and electrical isolation. Their performance across a wide temperature range supports reliable signal integrity and prevents ground loops in mixed-voltage architectures.

6) Aerospace & Defense

Avionics, engine controls, and high-power electronics demand components that survive extreme vibration, heat, and rapid thermal events. Mica’s stability and low outgassing make it a trusted choice where maintenance windows are scarce and reliability is paramount.

Design & Selection Guide

- Temperature profile: Define continuous vs. peak temperatures. Choose phlogopite for higher peaks, muscovite for stronger dielectric stability.

- Electrical clearance: Consider required dielectric strength and creepage distances. Thicker washers may raise isolation margins.

- Mechanical preload: Validate compressive stress vs. thickness to avoid creep. Distribute load via larger OD where needed.

- Chemical environment: Check exposure to oils/solvents; mica generally resists most industrial fluids.

- Geometry: Match ID to bolt/screw with proper tolerance; consider keyed/slotted designs to prevent rotation.

- Compliance: Determine if UL, RoHS, REACH, or industry-specific standards apply to the end product.

Installation & Handling

- Surface prep: Ensure mating surfaces are clean, flat, and free of burrs to prevent stress concentrations.

- Torque control: Apply recommended torque to avoid crushing thin sections; validate via assembly trials.

- Stacking: Where additional isolation is needed, stacked washers can be used—verify heat transfer and preload.

- Storage: Keep in dry, shaded conditions; avoid high humidity prior to assembly for best dielectric results.

- Inspection: Periodically check for mechanical damage during service intervals, especially in high-vibration systems.

Packaging & Delivery

Standard export packaging uses inner poly bags and outer cartons with protective labeling. Bulk shipments can be palletized to prevent compression. Typical lead times are 7–15 business days for standard sizes; custom geometries follow drawing confirmation and tooling (if required). We ship globally via air express (DHL/UPS/FedEx), air freight, or sea freight with commercial documentation prepared on request.

Certifications & Compliance

- UL 94 flame performance (V-0 systems available).

- ISO 9001:2015 quality management.

- RoHS & REACH compliance for restricted substances.

- Asbestos-free declaration with third-party test options.

FAQ

1) What is the maximum working temperature?

Mica washers handle 500°C continuously and short-term peaks to 1000°C, depending on airflow, load, and dwell time. For applications with prolonged peaks, we’ll recommend material pairing and thickness.

2) Can I customize size and geometry?

Yes. Provide ID/OD/thickness or a drawing (DXF/DWG/PDF). We also support slots, countersinks, keys, and multi-hole patterns. Tolerances are tailored to the assembly stack-up.

3) Can mica replace PTFE washers?

If your application faces heat >200°C or requires flame resistance, mica is typically superior. For low-temperature chemical resistance where flexibility dominates, PTFE may suffice.

4) What dielectric strength should I expect?

Typical values exceed 20 kV/mm, but assembly cleanliness, humidity, and edge finish matter. Request a datasheet and consider testing in your exact assembly.

5) What are the MOQs and lead times?

We offer flexible MOQs for prototypes and scale with volume. Standard sizes ship in 7–15 days; custom parts follow tool-up (if needed) and validation runs.

6) Can you supply certificates?

Yes—material certificates, RoHS/REACH statements, and test reports are available per order. For regulated sectors, we provide batch traceability.

Contact Us

Ready to specify mica insulation washers for your project? Our engineering team can validate material selection, recommend thickness and geometry, and provide rapid samples for fit and function testing.

Recommended Products