How to Choose Phlogopite Mica Sheets for Your Project

Have you ever struggled to find an insulation material that can withstand extreme heat without losing its mechanical strength? Many industrial users face this issue when working with high-temperature applications. Ordinary insulation often breaks down under stress, causing equipment failure and safety risks.

This is where Phlogopite mica sheets come in. With their excellent thermal resistance and mechanical stability, they provide a reliable solution for industries requiring safe and durable insulation. In this guide, we’ll explain what Phlogopite mica sheets are, why they matter, how they work, and what to look for when choosing them.

Definition and Importance

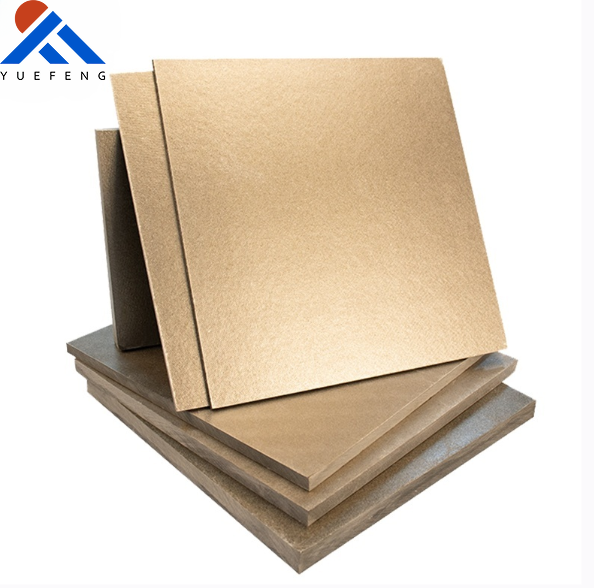

What are Phlogopite mica sheets? Phlogopite mica sheets are rigid insulating boards manufactured from phlogopite mica paper bonded with high-temperature resistant silicone resin. Known for their golden-brown appearance, they are designed to handle continuous high temperatures up to 1000°C, making them indispensable in environments where other insulating materials fail.

Why are they important?

Ensure thermal and electrical insulation in demanding conditions

Maintain structural stability under mechanical stress

Widely used in steel, foundry, glass, and electrical industries

Enhance safety and energy efficiency of equipment

How They Work / Main Types

How do Phlogopite mica sheets work? Phlogopite mica has a layered crystal structure, which gives it excellent cleavage and flexibility. When processed into sheets, it retains high thermal resistance and provides stable electrical insulation even under direct flame exposure.

Main types of mica sheets include:

Phlogopite Mica Sheets – Best for high-temperature applications

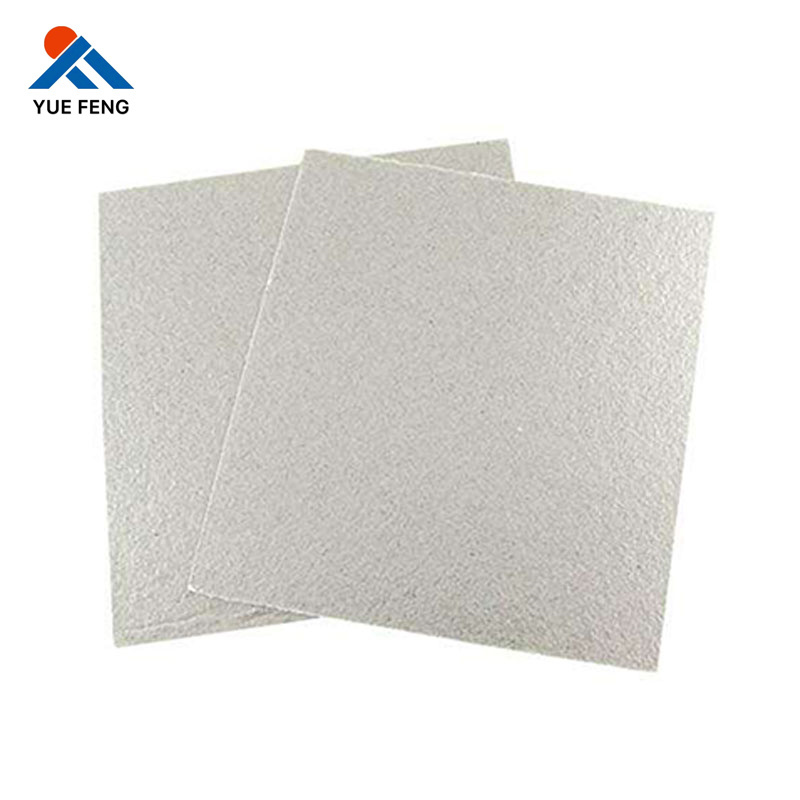

Muscovite Mica Sheets – Superior electrical insulation, lower heat resistance

Synthetic Mica Sheets – Consistent quality, used in specialized industries

Key Decision Factors

When selecting Phlogopite mica sheets, consider:

Temperature resistance – Can it withstand up to 1000°C?

Mechanical strength – Ability to resist cracking under load

Electrical insulation – Compliance with safety standards

Thickness & density – Fit for the intended industrial use

Certification – ISO, RoHS, REACH compliance

| Attribute | Value Example | Why It Matters |

|---|---|---|

| Material | Phlogopite mica + resin | Ensures thermal & mechanical stability |

| Thickness | 0.1–100 mm | Determines flexibility & durability |

| Temperature limit | Up to 1000°C | Essential for furnace & foundry use |

| Dielectric strength | >15 kV/mm | Provides electrical insulation |

| Applications | Furnace, foundry, glass | Defines industrial suitability |

FAQ: Phlogopite Mica Sheets

Q1: What is the difference between Phlogopite and Muscovite mica sheets? Phlogopite mica sheets withstand higher temperatures (up to 1000°C) but offer slightly lower electrical insulation compared to muscovite sheets.

Q2: Are Phlogopite mica sheets safe for electrical applications? Yes. They provide excellent dielectric strength and thermal stability, making them ideal for motors, transformers, and heating elements.

Q3: Where are Phlogopite mica sheets commonly used? They are widely used in furnace insulation, glass production, metallurgy, and high-temperature sealing applications.

Q4: Where can I buy high-quality Phlogopite mica sheets? You can explore industrial-grade mica products at .

Conclusion

In summary, Phlogopite mica sheets are an essential insulating material for industries that require both high thermal resistance and mechanical strength. By understanding their properties, differences from other mica sheets, and the factors to consider when purchasing, you can make better decisions for your applications.

Previous Page