Mica machining parts

Product Category:

Mica Machining Parts

Keywords:

Yuefeng Mica

- Description

-

- Commodity name: Mica machining parts

Excellent Electrical Insulation Performance : Mica parts have a dielectric strength ranging from 15-40kV/mm (depending on the mica type), effectively preventing leakage current across a wide voltage range from 1kV low-voltage systems to 110kV high-voltage systems. This makes them ideal for protecting electrical components and ensuring smooth operation.

High-Temperature Resistance : Depending on the mica type, they can withstand continuous operating temperatures between 400°C and 1000°C while maintaining structural integrity and insulation properties. This characteristic makes them suitable for applications frequently exposed to extreme high temperatures, such as industrial furnaces, motor housings, and exhaust systems.

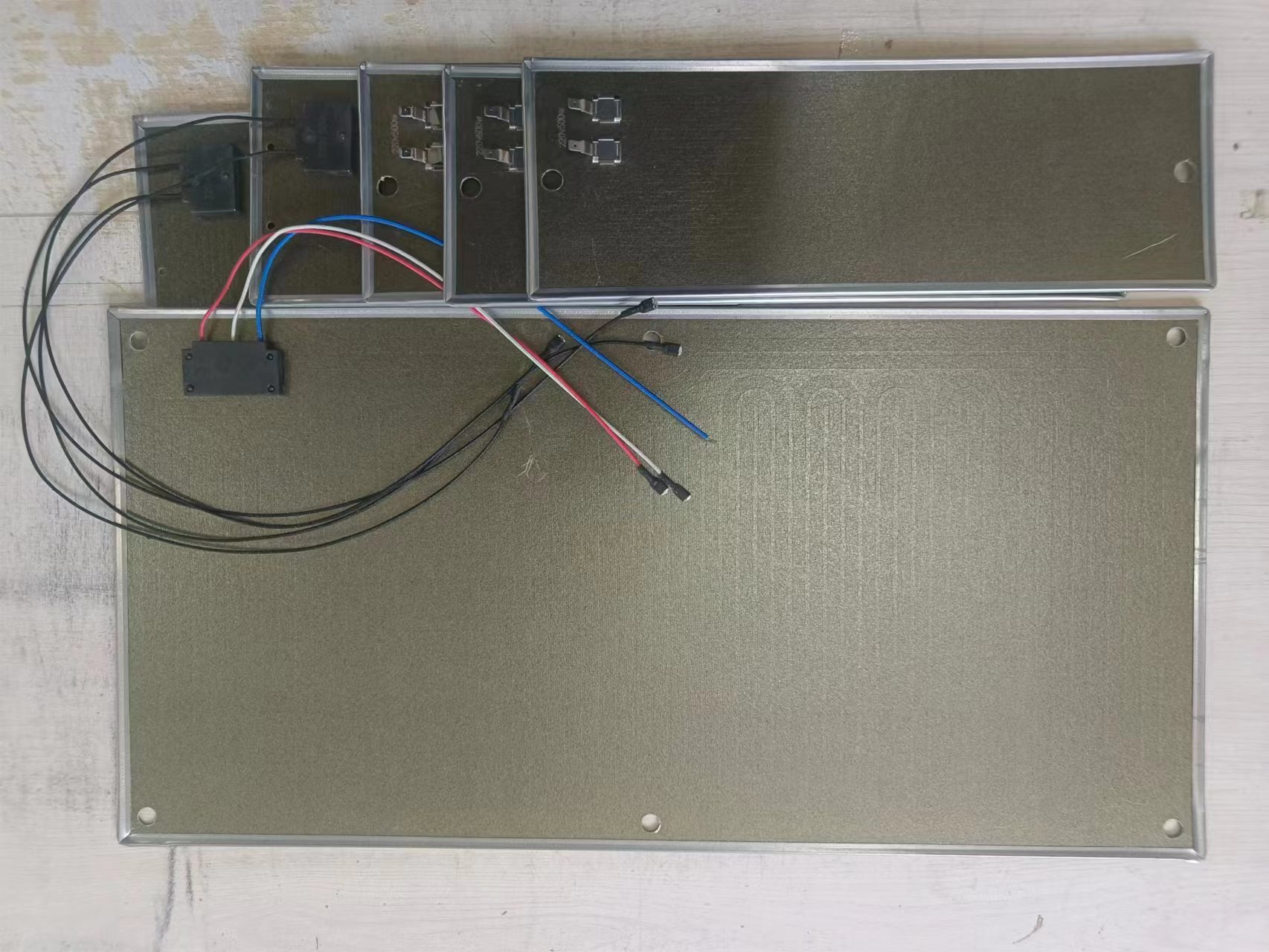

Precision Machining : These parts can be customized into complex shapes such as washers, rings, slots, and irregular geometries, with high machining accuracy, typically with tolerances as low as ±0.05mm. This precision ensures a perfect fit in mechanical equipment, minimizing the risk of mechanical failure and improving overall equipment efficiency.

Mechanical Durability : Despite their lightweight nature, they possess very high rigidity and can resist deformation caused by mechanical stress or vibration. This characteristic makes them suitable for long-term use in moving parts, contributing to the durability and reliability of industrial equipment.

Flame Retardant and Chemical Corrosion Resistance : Rated as non-combustible material according to UL94 V-0 standard, they do not contribute to combustion and do not produce toxic fumes in case of fire. In addition, they have strong oil resistance, weak acid resistance, and alkali resistance, suitable for harsh industrial environments with high risk of chemical exposure.

Low Thermal Conductivity : By reducing heat transfer between components, they play a crucial role in improving energy efficiency in high-temperature systems. This characteristic helps maintain the optimal operating temperature of mechanical equipment and reduces energy consumption.

Specifications

Material Selection : White mica is suitable for applications with temperature requirements of 400-600°C, with good insulation and mechanical properties. Golden mica has a temperature range of 600-800°C, with higher heat resistance. Synthetic mica can withstand temperatures up to 1000°C and is the preferred material for extreme high-temperature applications.

Dimensions : Custom sizes are available, with length and width ranging from 5mm to 500mm and thickness ranging from 0.1mm to 10mm. Precision grinding services are also available to meet the requirements for more precise fitting.

Tolerances : Standard tolerances are maintained at ±0.1mm, but high-precision options as low as ±0.02mm can be achieved for critical applications. This precision ensures consistent performance and compatibility with other components.

Surface Finish : Surface finish can be customized to a smooth surface (Ra ≤0.8μm) to reduce friction; or a textured surface can be customized according to application needs to enhance bonding or meet other specific requirements.

Application Areas

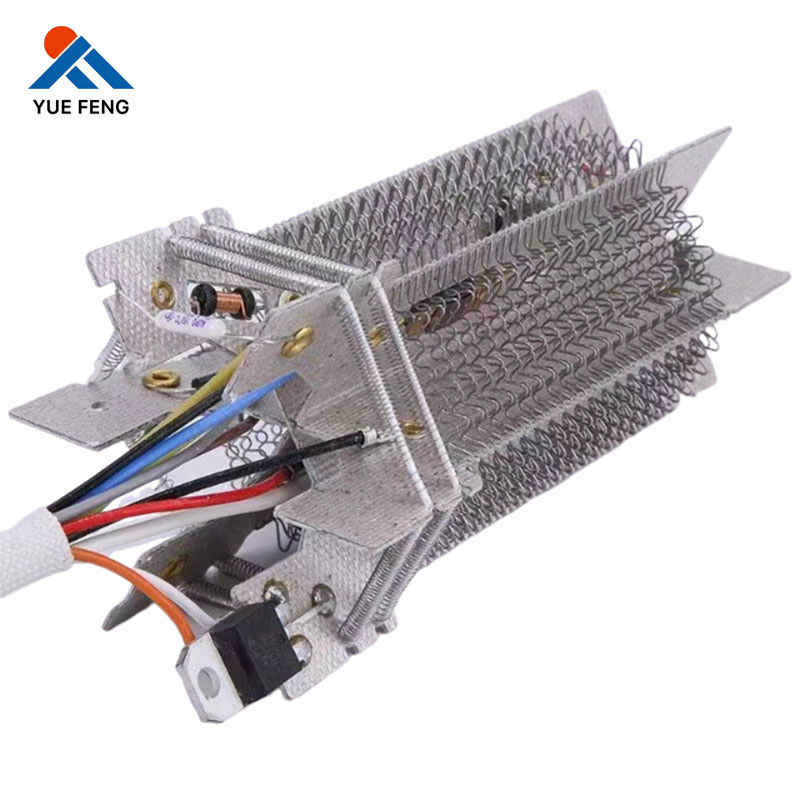

Electrical Equipment : In motors, they are used as insulating washers to prevent short circuits and ensure smooth rotation of the shaft. In transformers, they are used as separators between windings to enhance insulation and heat dissipation. In switching equipment, they are used as seals to provide sealing and prevent arcing.

Industrial Furnaces : They act as heat-resistant barriers in kilns, furnace doors, and heating elements, protecting metal parts from high temperatures, extending equipment life, and ensuring safe operation.

Automotive and Aerospace : In automotive applications, they are used as insulating components in engine compartments, exhaust systems, and battery packs, where they need to withstand high temperatures and vibrations. In the aerospace field, they play a similar role in aircraft engines and electrical systems, where reliability and performance are critical.

High-Voltage Systems : Custom rings and sleeves made of mica components are used for busbars, cables, and reactors in power distribution networks. These components ensure reliable insulation, prevent electrical breakdown, and maintain the stability of the power grid.

Medical and Scientific Instruments

Category Detailed Description Processing Capabilities Designed and molded according to customer requirements, processed into various mica products (tubes, stamped parts, molded parts, gaskets) through stamping, sawing, milling, turning, drilling, grinding, etc. Equipment Configuration Automated production equipment, including high-precision large CNC lathes, laser engraving machines, 3D molding machines, etc. Service Advantages 1. Years of practical experience

2. Capable of customized R&D design and collaborative development

3. High value-added product experience and solutionsApplication Areas Home appliances, electromagnets, power engineering, metallurgy

Ships, energy storage, new energy vehicles, military industry

Recommended Products