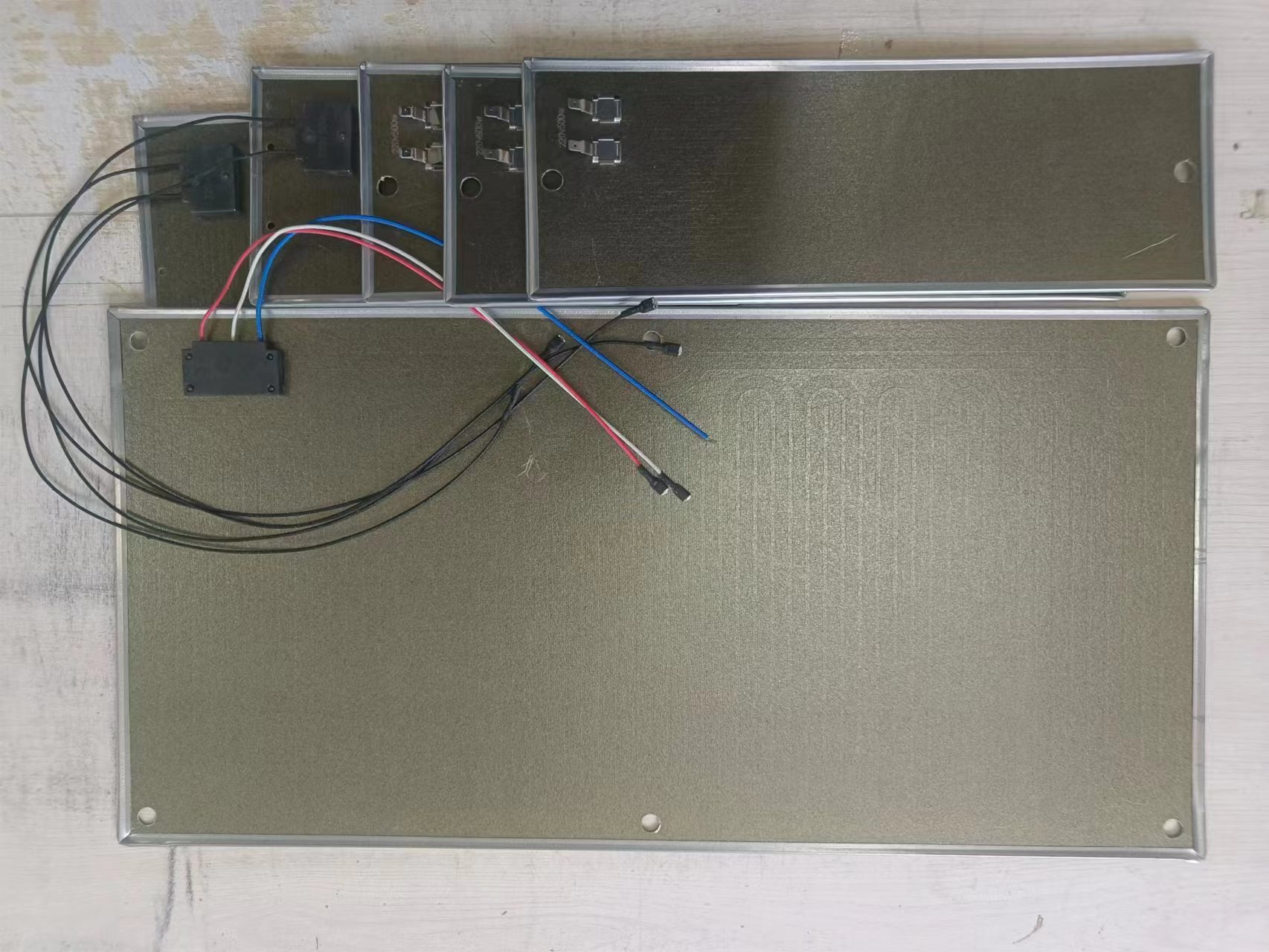

Thick mica plate

Product Category:

Mica Plate

Keywords:

Yuefeng Mica

- Description

-

- Commodity name: Thick mica plate

Superior Structural Strength :With a thickness of 3mm or more, it has high bending strength (≥120MPa), can withstand heavy loads and vibrations without deformation, and can be used as a reliable spacer or baffle plate in large machinery.

Enhanced Heat Resistance :Remains stable at continuous operating temperatures of 400°C to 1000°C (depending on the mica type), superior to thinner sheets in extreme high-temperature environments such as kilns and foundry equipment.

High Electrical Insulation :Dielectric strength of 15-30kV/mm, suitable for medium and high voltage (10kV-50kV) systems, effectively preventing arcs and short circuits in power distribution equipment.

Flame Retardancy :Classified as non-combustible material according to UL94 V-0 standard, it is flame retardant and does not release toxic fumes, ensuring the safety of enclosed industrial sites.

Excellent Dimensional Stability :Low coefficient of thermal expansion (≤7×10⁻⁶/°C) minimizes warping under temperature fluctuations and maintains precise fit during long-term use.

Chemical and Moisture Resistance :Resistant to oil, weak acids and alkali corrosion, moisture absorption rate ≤1.0%, ensuring service life in humid or industrial environments.

Specifications

Thickness :3mm-20mm, customizable options to meet specific insulation and structural requirements.

Sheet Size :Standard size range is 400×400mm to 1200×1200mm; can be customized cutting according to the integration needs of large equipment.

Density :1.8-2.3g/cm³, balancing strength and weight in heavy-duty applications.

Resin Type :Silicone resin, with the highest high-temperature resistance (up to 1000°C); epoxy resin, cost-effective performance at moderate temperatures (up to 500°C).

Application Areas

Industrial Furnaces :Used as insulation lining, door seals and heat shields for high-temperature furnaces, protecting structural components from extreme high temperatures and reducing energy loss.

Large Transformers and Generators :Used as a thick insulating layer between windings and core structures, providing both electrical insulation and mechanical support in power generation equipment.

Heavy Machinery :Used as insulating spacers in hydraulic systems, large motors and mining equipment, where durability and vibration resistance are critical.

Nuclear Power and Energy Facilities :Used in high-voltage switchgear and reactor components, capable of withstanding the harsh conditions of nuclear power plants and thermal power systems.

Aerospace and Defense

Unit UTM - M (Ultra-Thick White Mica Mica Sheet) UTM - P (Ultra-Thick Phlogopite Mica Sheet) Test Method Mica Paper / Muscovite Phlogopite / Mica Content % ≥90 ≥90 IEC 60371 - 2 Binder Content % ≤10 ≤10 IEC 60371 - 2 Density g/cm³ 2.0 - 2.35 2.0 - 2.35 IEC 60371 - 2 Temperature Resistance (Continuous Use) ℃ 500 750 / Temperature Resistance (Intermittent Use) ℃ 700 900 / Heat Loss at 500℃ % ≤3.5 ≤3.5 IEC 60371 - 2 Heat Loss at 700℃ % ≤2 ≤2 IEC 60371 - 2 Bending Strength MPa >200 >200 GB/T 5019.2 Compressive Strength MPa >300 >300 Internal Standard Water Absorption % <1 <1 GB/T 5019.2 Electrical Strength kV/mm ≥15 ≥14 IEC 60243 - 1 Flammability Rating / UL94 V - 0 UL94 V - 0 UL94 Volume Resistivity Ω·cm >10¹⁷ (23℃), >10¹² (500℃) >10¹⁷ (23℃), >10¹² (500℃) IEC 60093 Thickness Range mm 2 - 150(Tolerance: 2 - 7 mm ±8/-6%; 8 - 30 mm ±7/-5%; 31 - 150 mm ±5/-3%) 2 - 150(Tolerance: 2 - 7 mm ±8/-6%; 8 - 30 mm ±7/-5%; 31 - 150 mm ±5/-3%) Technical Parameters

Recommended Products